Outdoor lighting is necessary for the normal functioning of cities. First of all, street lamps provide safety, but can also be used to decorate parks and squares. When installing a street lighting system, an important point is the choice of lampposts. The most popular are reinforced concrete and concrete lighting poles, due to its strength and reasonable price..

Content

- Light support classification

- Features of reinforced concrete structures

- Installation of outdoor light poles

Trunk lighting provides good visibility on highways in the dark

Light support classification

1. According to the material of manufacture:

- reinforced concrete – able to withstand heavy loads and sudden changes in temperature;

- concrete – durable, but have an unattractive appearance;

- metal – durable and aesthetically attractive;

- fiberglass – lightweight, more weather-resistant than metal, are available in a variety of colors;

- wooden – subject to faster decay, break when strong winds.

2. By type of construction – can be tubular, multifaceted, conical or trellised.

3. According to the purpose of use, they distinguish:

- street;

- trunk;

- decorative.

Features of reinforced concrete structures

Reinforced concrete lighting poles inside are hollow, but reinforced with metal fittings for added strength. Granite crushed stone is used as a filler, which has high frost resistance.

It is important that reinforced concrete is not susceptible to corrosion and is very resistant to destruction. Such supports, although not aesthetically attractive, are reliable and can last up to 50 years. They do not collapse when the temperature drops from -55 to +50 degrees Celsius.

Advantages include fire resistance and ease of maintenance. And thanks to the reinforcement, they can withstand loads many times greater than those that withstand concrete columns of lighting.

The movement and installation of lighting poles is carried out using special equipment.

It is important to know that in case of emergency, the reinforced concrete structure can cause great harm. The weight of such supports is much more than metal or wooden.

The advantage of reinforced concrete light poles is their resistance to adverse environmental influences.

Installation of outdoor light poles

Installation of lighting poles is an important stage of construction work in the integrated development and installation of an outdoor lighting system.

In order to do this correctly, it is required:

- develop a lighting network diagram;

- mark up on the ground;

- dig trenches for cable;

- drill holes;

- prepare the foundation;

- mount poles;

- install electrical wires.

The distance between the lighting poles must be calculated in accordance with the planned loads and power..

When developing a scheme, you immediately determine the optimal location of the lights and their number. It is important to immediately select the method of turning on and disconnecting from the network.

Also, depending on the purpose of using the lighting design, the height of the lighting column is selected.

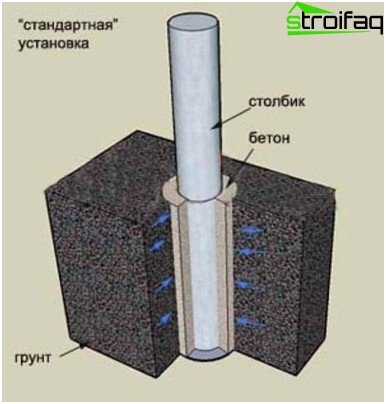

The concreting method can be used to strengthen supports made of reinforced concrete and metal. For this, the soil is first drilled taking into account preliminary marking. Given the height and thickness of the column, the depth of the hole is determined. This work is performed by special equipment with earthen or telescopic drills, which are placed on a car platform..

The concreting method is simple and reliable.

The diameter of the hole should be 20 cm larger than the diameter of the column. If the soil is very soft, then sand and granite crushed stone are laid in the pit, about 15 cm. And only after that we install the column. In order for it to be strictly upright, special temporary struts are used. The remaining voids are poured with concrete to the soil level..

For higher lampposts, a flange fixing method is used. It is necessary to use a ready-made monolithic concrete block with a mortgage anchor with studs to which the flange is attached. The block is lowered into a pit with a pillow of sand and gravel, the soil around this block is carefully rammed. Flange must be secured with nuts..

Installation is best done using special equipment

It is important to remember that the installation of lighting poles, especially work with wiring, requires certain knowledge and the use of special equipment and technology. Therefore, it is better not to undertake this work on your own, but to trust specialists in this field.