Lighting poles

It has long been customary to understand that lighting poles (also called street lighting poles or lampposts) are public lighting equipment, state-owned, and therefore no man’s. The issue of choosing lampposts, as well as information about the features of installation and fastening passed by ordinary inhabitants, were beyond their interests. It goes without saying that the equipment for parks and squares, highways and shopping centers should be efficient and low cost, the aesthetic side of the issue usually remains on the side. So how to be happy owners of country houses and household plots? Is it possible to combine optimal photometric characteristics, ease of use, modern design and a high degree of protection against environmental influences in relation to a lighting installation for a personal plot? – Let’s try to figure it out. Lampposts are different both in the material of manufacture, and in the type of construction, and in the method of installation, and in the purpose of use. Consider the varieties in more detail.

Content

- Post classification for lighting

- Reinforced concrete lighting poles

- Lighting poles made of metal

- Galvanized metal surface

Post classification for lighting

- According to the material of manufacture (reinforced concrete, metal, fiberglass, wooden).

- By type of support structure (tubular, multifaceted, conical, trellised).

- By purpose of use.

Lampposts are made of metal (simple or galvanized), reinforced concrete, composite materials (fiberglass), sometimes you can even find wooden lampposts, often used in villages and forest areas. Wood, even after processing with special impregnations, is still less resistant to atmospheric conditions than steel and concrete, with a strong wind or when the wires freeze, a wooden pillar can break, unable to withstand the loads. Therefore, it is logical that wooden structures are often replaced by more modern ones: metal, reinforced concrete or fiberglass.

Reinforced concrete lighting poles

Reinforced concrete lighting poles inside are hollow, reinforced with metal fittings for extra strength. Routing street lighting or transmitting electricity over significant distances is possible using reinforced concrete lighting poles of the proper size and type. The cost of reinforced concrete lighting poles is significantly lower than metal. But the appearance of massive structures is a little aesthetic, in addition, moving and installing them, very time-consuming and costly, is possible only with the use of heavy special equipment. Another important feature: in the event of an emergency, a reinforced concrete structure will do much more harm than a less heavy metal.

Reinforced concrete lighting poles are not easy to install, they are not attracted by their massiveness and lack of aesthetics

Technological progress is not limited to the search for high-strength materials for sustainable designs. The ability to smoothly adjust lighting (depending on the natural level of illumination), the use of lamps with increased light output, which, in fact, will significantly increase the distance between the lighting poles, without compromising the level of illumination – this is an incomplete list of tasks that are relevant today.

Recently, cheaper metal posts with iron castings have been replaced by cheaper plastic and composite materials, and instead of traditional incandescent lamps, more economical LED light sources are used.

Lighting poles made of metal

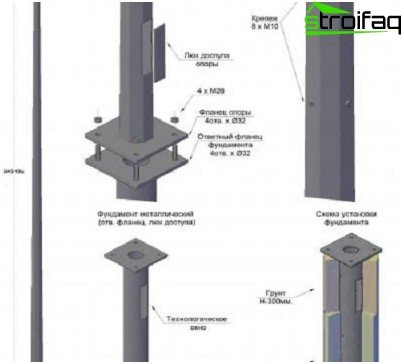

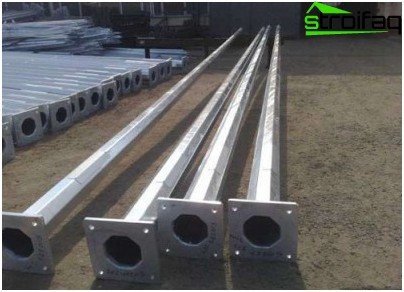

Lampposts made of 4 mm sheet steel, usually conical, multifaceted, height from 3 to 12 m. The lower part of the support is equipped with a hatch with a cover of the proper size (for installation and repair). Using the appropriate type of flange, underground installation or fastening and installation on a concrete foundation is carried out at the bottom of the column.

Lamppost mounting flanges

Lighting fixtures are usually mounted at the top of the column. The height of the lighting column, as well as the power of electric lighting devices affect the degree of illumination. The height of decorative park fixtures usually does not exceed 3 m. The weight of the structure depends on the thickness of the metal and the height of the support. Usually for metal fixtures up to 1 m long (various decorative lampposts for the garden), a weight of about 30 kg is typical. In the upper part of the supports, brackets for mounting fixtures are attached, with further attachment of lighting devices. The cost of the metal structure largely depends on the applied anti-corrosion coating. The most commonly used method of hot galvanizing, it is possible to use paint coatings or powder coating in the factory.

Lighting poles made of metal are durable, elegant, poles with a galvanized surface are not oxidized and do not rust

Galvanized metal surface

Is it advisable to expose an already strong metal structure to hot-dip galvanizing? In the process of galvanizing, zinc atoms penetrate the metal on the metal surface (diffusion), and a high-strength alloy is formed on the surface, which reliably protects the metal structure from corrosion (the ability of zinc, as a more active metal, to oxidize in the first place, guarantees the safety of the metal due to the active electrochemical protection).

Under the influence of weather conditions, the protective layer is gradually thinning (about 1.5 microns per year), a layer thickness of 80 microns guarantees the protection of the metal structure for 30 years. As you can see, the use of galvanized structures guarantees a significant excess of the normal life of the lighting support.

The distance between the lighting poles is calculated in accordance with the planned loads and power. Metal poles are resistant to moisture and temperature changes, wind resistance, durability (the service life of metal poles up to 75 years). Galvanized coating significantly extends the service life and saves money on maintenance (periodic painting is not required). The form for the lighting poles can be multifaceted, round or conical, and a lighting device (spotlight, lamp, lamp) is held on a support and.

Distinguish between decorative, trunk, sports, street supports. The use of metal poles is possible for arranging both functional and decorative lighting; suspended, console and floor lamps are installed on poles. The steel lighting poles can be painted, and the aluminum poles are very light, which simplifies the transportation and installation of lighting poles.

Installation of lighting poles

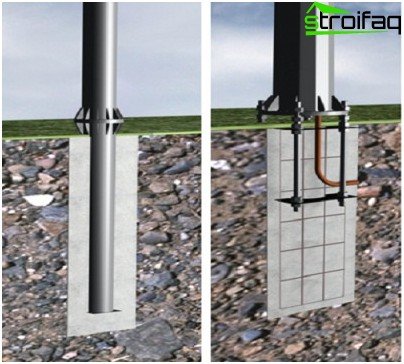

To install a lighting column, a reinforced concrete foundation with a mortgage anchor with studs, to which the column flange is attached, is required. Such a foundation can be a finished block reinforced concrete product or made on site by pouring concrete into a specially prepared formwork with a welded reinforcing structure.

Installation of lighting poles requires foundation

We examined the features of various types of lighting poles. Concrete lighting poles – relatively inexpensive, durable, but very massive and require significant installation effort, aesthetically unattractive.

Metal poles come in various designs, varying in height and purpose, perhaps they are not the cheapest, but, nevertheless, this type of lampposts is the most popular. Numerous decoration options for metal lighting poles make it possible to consider a lamppost as an important element in the design of a garden or garden. Installation of metal lampposts is carried out in accordance with regulatory enactments by organizations having the appropriate license.