Pipes for electrical wiring

Pipes – products characterized by a wide range of applications. They are used not only to organize the transportation of liquid media, but also for the manufacture of a variety of structures or in the implementation of electrical work. For example, a PVC pipe for electrical wiring is an important component of protecting communications from damage, which is being used more and more often. Moreover, modern fire safety standards require the use of plastic pipes, rather than metal. Why? We will understand together! Content

- Types of pipes for wiring

- Steel pipes, characteristic

- Copper pipe rating

- Plastic pipes for electrical wiring

- Technological corrugated pipes

Types of pipes for wiring

The pipe is designed to protect the wiring from mechanical stress and environmental aggression. Depending on the material, pipes for electrical wiring of the following varieties are distinguished:

Steel pipes, characteristic

Steel pipes are hard to install, the material is subject to corrosion

The main disadvantage is that steel pipes are subject to corrosion, even painting does not always solve the problem. Installation is a laborious process that requires compliance with certain rules:

- pipe sections should be cleaned and countersinked;

- bends should be made at an angle of 90 degrees. If 2 bends are required, the length of the pipe should not exceed 5 meters;

- when bending, make sure that the cross section of the pipe does not decrease;

- to prevent corrosion, installation should be carried out with a slight slope towards the distribution box;

- steel pipes for electrical wiring should be part of the equalization of forces, as being conductors, they acquire unnecessary electrical potential.

Copper pipe rating

Copper is a corrosion resistant, ductile material that is prized primarily for its durability. Among other things, copper pipes for electrical wiring are quickly mounted, but even these wonderful qualities are not able to maintain the popularity of the material, which in many respects loses to plastic counterparts.

Copper pipes for electrical wiring are resistant to the entire spectrum of external influences, but are not encouraging

Excellent thermal conductivity contributes to the need to protect cables inside from extreme temperatures.

It is important! When crossing heating pipes and electrical wiring, the distance between them must be at least 50 mm. If the pipes are parallel, then this indicator should correspond to 100 mm.

Metal pipes for electrical wiring have other drawbacks – impressive weight, high cost and the need to use specialized equipment for installation.

Plastic pipes for electrical wiring

Plastic pipes can be attributed to the new generation of materials, which have a lot of undeniable advantages compared to heavy metal samples..

Benefits

- high chemical and corrosion resistance;

- long term of operation (about 50 years);

- low specific gravity facilitating transportation and installation;

- lack of need for protection of wires;

- fluid accidentally entering the pipe will not damage it;

- the flexibility of small diameter specimens;

- relative cheapness;

- the possibility of installation without specialized knowledge and skills.

Features of PVC pipes

They are made of non-combustible polyvinyl chloride by continuous extrusion and are characterized by a low coefficient of linear expansion, rigidity and resistance. Indispensable for broaching wiring in concrete structures. PVC pipes are available in different sizes – from 16 to 50 mm. The length of the segments can reach 3 meters.

Plastic pipes have many advantages: easy to install, strong, inert, durable

Smooth pipes are oriented towards mechanical protection and additional cable insulation. Ideal for open ceiling wiring made of non-combustible / low combustible materials. There are a large number of types of PVC pipes: rigid, smooth, reinforced, corrugated. Each type has specific features that determine the features of use. So, for example, smooth-walled rigid pipes are designed for distribution of wires in the walls of industrial, administrative and residential buildings. Their main task is to create the most reliable electrical wiring system..

Characteristics of polyethylene pipes

LDPE (high pressure polyethylene) was obtained in the 30s of the XX century. The simplest material to manufacture was soon replaced by HDPE (low pressure polyethylene). These polyethylenes differ not only in density and thickness, but also in characteristics.

The surface of the piping does not require additional processing

It is important! The main difference is that LDPE is sensitive to oxidation and the effects of gases. HDPE also has high water resistance and chemical resistance, but low resistance to shocks and is used to organize drinking water supply, as well as an insulator when laying a cable in the ground.

Pnd pipes are smooth, single-walled. They can be poured with concrete or easily mounted in masonry. The connection occurs through tees, bends, couplings, etc..

The advantages of polyethylene pipes

- service life more than 50 years;

- The PND pipe for electrical wiring does not break at low temperatures;

- the diameter of the pipe remains unchanged throughout the entire “life” period, no deposits appear inside, moisture does not condense outside;

- the surface is flat, not requiring painting or any other treatment;

- safe, do not emit toxic substances, work with them does not require special precautions;

- low weight and reasonable cost.

Technological corrugated pipes

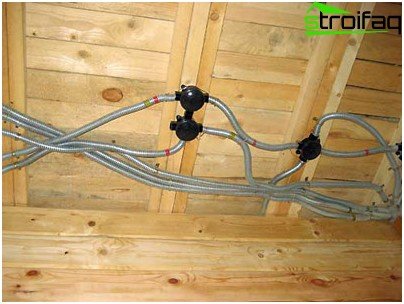

The corrugation process increases the rigidity of the structure. Corrugated pipe for electrical wiring is made of non-combustible plastic and is a flexible channel with a circular cross section, withstanding voltage up to 1000 volts. Such pipes become a real salvation when installing suspended ceilings and raised floors: elastic sleeves are indispensable for laying cables in hard-to-reach places where installation of a rigid structure is impossible.

Corrugated pipes are easy to install, configuration of any complexity can be arranged with their help using a minimum of connecting elements

There are also superheavy samples designed for laying in concrete, cement screed.

Pay attention to the diameter:

- for sockets and switches – 20 mm;

- for lighting devices – 16 mm;

- for communication of distribution boxes and shields – 25 mm;

- for interfloor connections – 40 mm.

Advantages of corrugated pipes:

- increased insulation of wiring;

- reliable protection of the wire from mechanical stress;

- lack of need for additional accessories;

- the ability to lay pipes along the most favorable path (due to bends);

- protection of wires from fire, as the pipe is made of non-combustible material.

It is important! Corrugated pipes will help to install television, computer and telephone networks. The desired diameter is selected in accordance with the thickness of the wire and the purpose of the device connected to them.

Open corrugation wiring of self-extinguishing material – the best choice for home furnishings made of wood

Ease of installation is another feature of corrugated pipes. They are lightweight, easy to transport and, being dielectrics, do not need grounding..

Rules for installing pipes for electrical wiring

- electrical work is carried out in 2 stages. First, mark the location of the ends of the pipes that are suitable for the switchboard, power receiver, control unit, and then determine the wiring paths, attachment points, corner angles, installation locations of boxes;

- plastic pipes bend at a temperature of 100 degrees. Work must take into account environmental conditions. In order not to collect moisture, pipes should be laid with a slight slope;

- the metal parts of the wiring are nullified and ground using a flexible copper jumper from the pipe to the body. The use of grounding nuts is allowed;

- blow the pipes before tightening, after which they are leveled;

- in the boxes leave a supply of cable for connection. The connection is made exclusively in boxes, this can not be done in pipes. Resistance between wires and pipe must be at least 0.5 MΩ.

The results of electrical work can be closed with a suspended ceiling

Sealing of joints is done through fittings and couplings. Remember, the installation must be carried out so that the wires can be removed if necessary.