Masonry stoves and fireplaces

How pleasant it is on a cold rainy evening, when streams of rain are pouring outside and the wind is noisy, to sit down by the fire with your favorite newspaper and a cup of hot tea. Dream, you say? Not at all, because if you really want to, even the most incredible dreams turn into reality. The calm and warmth of the home atmosphere is a merit not only of all family members, but also of the hearth, fireplace. Laying fireplaces will create a cozy atmosphere and bring a special detail to the interior – a symbol of happiness, prosperity and prosperity.

Content

- Fireplace – resurgent popularity

- Masonry fireplace masonry: where to start?

- What is a masonry scheme?

- Special material and solution

Fireplace – resurgent popularity

A fireplace is an attribute of the unique look of your home, experiencing a rebirth today. Furnaces of various forms and options of facing can rightfully be called the best decoration, which will give warmly dank autumn evening, and the mood, if necessary, will raise, and gather close people together. In addition, the fireplace, which few know about, prevents the formation of dampness and an unpleasant smell, this becomes possible due to the constant movement of air in the room.

The fireplace will organically fit into any interior

Masonry do-it-yourself fireplaces – a laborious process that requires a careful and responsible approach, because the result will depend on it.

Masonry fireplace masonry: where to start?

The most common type of material for building a fireplace is brick. Brick fireplaces fit seamlessly into any interior. The process of arrangement, although it seems very complicated, with the competent organization of the progress of work, it is quite feasible with our own hands.

To simplify the task and coordinate the procedure, it is necessary to develop a styling scheme.

What is a masonry scheme?

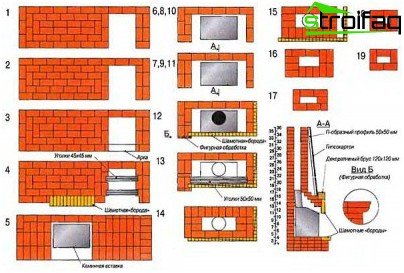

The masonry scheme, drawn up correctly, is half the success, because it reflects all stages of work, which helps to avoid irreparable errors. The masonry scheme should reflect the order of the fireplace, step by step, sequentially. You can develop such a drawing (if you have a great desire and relevant knowledge) yourself, or you can use ready-made samples, which, by the way, are plentiful on the Internet.

The masonry diagram clearly reflects the progress of work

And here are a few more interesting ordering options:

Fireplace ordering – option 2

English Fireplace Order – Option 3

Special material and solution

The laying of stoves and fireplaces is most often done from full-clay clay bricks. However, it is allowed to use other heat-resistant materials, for example, refractory brick or stone. For the front surface, you should choose the highest quality bricks that are absolutely identical in size and color, with right angles and a smooth edge.

The manufacture of stoves and fireplaces requires a special solution. The solution for laying the fireplace consists of cement, clay and sand. The cement content should be small and not exceed the required ratio: 1 part cement to 8 parts sand. First, dry sand and cement are mixed, and then clay is added. Full uniformity of the composition is necessary, the mixture should be a pasty consistency, without lumps.

You need to know! The quality of the components of the solution is crucial: sand should be sieved through a fine sieve, clay should not contain impurities. Clay before laying soaked in water until clay milk appears, which should also be filtered.

Corner fireplace: device specifics

A corner fireplace is one of the most beautiful ways to heat your home. This is due to the fact that the placement of a fireplace in a corner is very attractive in itself, and if at the same time the firebox opening is symmetrically oriented relative to the angular axis formed by the walls of the room, then you can’t imagine the best option for creating the original look of the house.

The corner fireplace organically looks both at the internal and external walls. The main thing is to take into account the location of the future pipe. If the fireplace will be located on the inner wall above the overhead roof, you should know that the chimney must be built above the ridge of the main roof.

It is important! With a long firebox, the pipe and the rear wall of the fireplace heats up quite strongly, therefore, in a wooden house, it is supposed to think over a plan of fire prevention measures.

Dimensions to be observed

The size of the fireplace is chosen, guided by the area and volume of the heated room. But if you determine this parameter yourself, then there are numbers that must be taken into account without fail. For example, the height and width of the furnace opening for a small fireplace is 2: 3 (height to width). The depth of the firebox is 1: 2 or 2: 3. These dimensions must be observed, because a smaller depth will cause smoke, and a larger one will reduce heat transfer.

The size of the smoke hole is selected in accordance with the area of the furnace hole, this value should be approximately 10 times smaller than it. To increase the heat transfer ability, the back wall of the firebox is tilted forward, starting from 1/3 of its height. Smoke box placed above the firebox.

It is important! Between the rear wall of the firebox and the smoke box, it is necessary to release a cornice, called a pass. It will prevent sparks and soot from escaping..

Ordering a corner brick fireplace

Intending to make a fireplace stove, ordering will be the main assistant for the quality of work. Ordering is a detailed diagram indicating the position of each brick. Whatever you ask in the search for “ordering: fireplaces” or “ordering: stoves, fireplaces” the almighty Google will provide you with the same information – ordering will allow you to accurately calculate the number of bricks, avoiding overpayments for materials.

Ordering a corner fireplace

It is important! Ordering is especially needed for inexperienced novice masters, as without it, it is unlikely to be laid without alterations. But this does not mean that professionals do not use order, even the virtuosos of their business do not neglect the help of such an important drawing.

Do-it-yourself fireplace laying

The construction of the fireplace is a multi-stage process consisting of several stages, each of which requires the utmost attention and responsibility..

Fireplace foundation

If we talk about the correct technology for the construction of furnaces, it will not be out of place to note that the foundation for the fireplace should be carried out separately from the foundation of the main building. First, a pit is prepared, the dimensions of which are larger than the dimensions of the future fireplace by 10 cm. The depth of the pit is 50-70 cm. The bottom is covered with a layer of rubble, after which the formwork is built.

It is important! Remember, the formwork height should be on average 5 cm below floor level.

In the formwork rubble stones are laid, which are then poured with a 3: 1 cement mortar (sand: cement). The foundation is leveled, covered with plastic wrap and left to shrink for a week.

Fireplace technology

It is necessary to lay a waterproofing material in 2 layers on the foundation. Then the base is laid, and the bricks of the basement are placed on the edge, while all the others are flat. The brick is soaked in water for several minutes before use. This is necessary to achieve strong contact with the solution..

Brick laying of the fireplace is carried out according to a clearly composed scheme

You need to know! The masonry scheme can be any, do not forget that the fireplace is an individual creation of building art.

If the masonry turned out to be inexpressive or brick defects were found, the stove can be plastered, or any other type of cladding can be used, which will help to hide errors without expensive alteration.

Overlapping – an important step

The method of laying the floor is of great importance for creating a complete composition. The furnace floor can be an original decoration. You can lay bricks in even vertical or horizontal rows, or you can create an arch effect. The role of additional decorative elements can be handled well by gems, wood, marble.

You need to know! The most expressive are wedge-shaped, arched and beam lintels, which are laid with a ledge.

Do-it-yourself masonry fireplace

Wedged lintels are made of bricks laid on the edge and aligned on the formwork. As a result, wedge-shaped seams are formed, the thickness of which should reach 3 mm, from above – 25 mm. Arched and beam lintels are laid on the formwork, corresponding in shape to the given shape. The laying of the lintel must be completed with a central brick placed strictly in the middle and vertically, relative to the overall dimensions of the furnace.

Freshly laid fireplace – the result of work

Before starting masonry, it is important to carefully study the scheme, think through the decor. It is difficult, and often impossible, to make corrections to the completed order. changing the position of even one brick leads to a change in all rows.

A correctly drawn up plan that fully reflects the stages of work, thoughtful decor, quality materials and your desire is all that is needed to create an interesting fireplace that will become a worthy decoration of the interior, bringing warmth and comfort.