Chimneys for fireplaces

The chimney is an essential part of the design of the fireplace. The duration and reliability of the functioning of the fireplace hearth depends on its qualities. The main task, which is assigned to chimneys for fireplaces, is considered to be the accident-free removal of combustion products. To ensure the stable operation of fireplaces, good traction is needed that enhances the combustion process. All structural elements that ensure the removal of smoke from the furnace into the pipe and further into the atmosphere are subject to increased fire safety requirements. This is especially true in wooden houses. In addition, the chimney should be convenient for repair and periodic cleaning of soot. Not the least role is played by the cost of the chimney device, the value of which is affected by the material, place of manufacture, as well as the complexity of installation work.

Content

- Design – the condition for perfect work

- The main types of chimneys

- Classic brick options

- Combined chimney made of brick and steel pipe

- Advantages of steel smoke exhaust systems

- Insulation – increased heat dissipation

- We use refractory ceramics

- Fireplace Chimney Layout: Shiedel UNI

- Spectacular glass chimneys new in the field of “hearths”

Design – the condition for perfect work

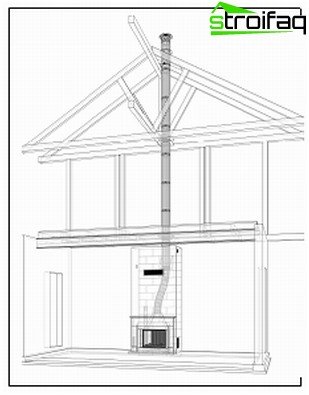

When designing fireplaces, special attention is paid to choosing the optimal design and the location of the chimney. The correctness of air circulation will depend on this. It is best to lay the device of the chimney for the fireplace in the project of the house in advance, that is, before the construction of the facility begins. This allows you to choose a fireplace and to design a chimney for its design, in accordance with the financial capabilities of the owner of the house.

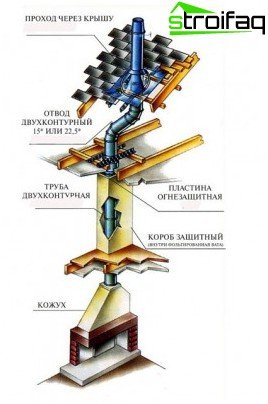

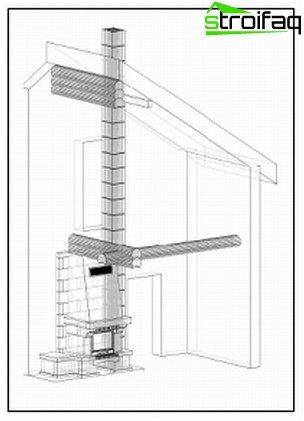

Typical structural diagram of the chimney

If the house is already purchased ready-made and a chimney is laid in it, then when choosing a fireplace, consult with specialists who conduct a survey of the smoke exhaust structure and give a conclusion about its compatibility with the chosen fireplace model.

There are also technologies for installing a fireplace and constructing a chimney in a finished house, from which specialists select the safest for a particular property.

Important! It is advisable to place the chimney closer to the ridge and in the warm part of the house. Otherwise, measures are taken to warm the walls of the structure to prevent freezing of the smoke channel. Otherwise, the fireplace will melt badly and smoke due to deterioration in traction. Inoperative, it can become a source of cold air and an unpleasant odor..

The main types of chimneys

Currently, there are many designs of chimney flues, among which you can find a device suitable for any country house. For the manufacture of chimneys, brick, concrete, ceramics, metal and even glass are used. Such a variety of materials allows you to develop various design solutions for interior decoration in a room with a fireplace.

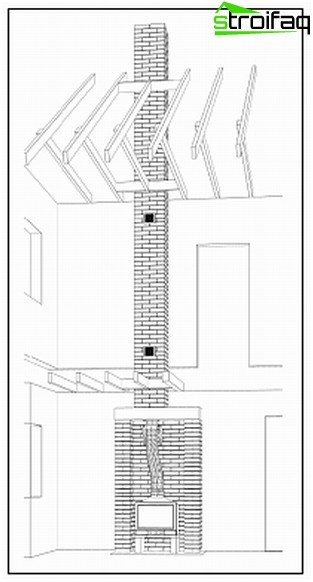

Classic brick options

This type of chimney device has been used since time immemorial. It requires high professionalism from a stove-maker who is able to perform high-quality installation of a chimney for a fireplace in the form of a brick shaft. Proper construction of the structure will allow it to serve for many years. The services of a specialist of this level are quite expensive. But the materials necessary for the construction of a brick mine are available: burnt brick, sand, clay and water. It must be remembered that this structure requires a solid foundation. Brick chimney built into the wall at the time of construction.

Brick chimneys

Combined chimney made of brick and steel pipe

Very often, a brick shaft, standing separately from the walls or built into them, is supplemented with a sealed thin-walled chimney pipe (rigid or flexible) made of stainless heat-resistant acid-resistant steel. This technological technique allows you to provide:

- absolute tightness of the smoke channel;

- optimal round shape;

- smooth walls that do not impede smoke;

- reduction of thermal load on the walls of a brick mine, as well as on materials of house structures in contact with the shaft from the outside.

Combined chimneys

Thus, a brick mine becomes a solid fence and an excellent heat insulator of a chimney made of metal. In this case, you can correctly use the intermediate space between the walls of the shaft and the chimney, creating special conditions for air circulation. Thus, the heat transfer of the structure increases and the temperature level on the external surfaces of the mine and the metal pipe decreases, which significantly prolongs their operational life.

Advantages of steel smoke exhaust systems

In already constructed private houses, the design of which does not provide for the installation of a chimney, steel structures are used, assembled from individual elements – metal pipes. Stainless chimneys have a lighter weight than brick mines, so devices do not require a separate foundation. Installation does not cause special difficulties, and such chimneys are usually suitable for all models of fireplaces.

The advantage of the metal pipes used for the construction of the smoke channel is the optimal cross-section of a round shape that does not interfere with the removal of combustion products. In the square and rectangular channels, local vortices form, which impede the movement of the smoke stream. In round pipes, this problem does not arise. Smooth walls of metal chimneys do not contribute to the accumulation of soot on them, which simplifies maintenance of the structure during operation.

Currently, steel chimney designs are presented on the market both from foreign manufacturers (Selkirk (England), Raab (Germany), FFBofill (Spain), Hild (France)), and domestic companies (Elits, NII KM (Moscow), Baltvent ( Kaliningrad), Rosinox (Wedge)).

Important! Domestic products with a quality certificate are not inferior to foreign counterparts, while its cost is much lower.

Insulation – increased heat dissipation

All metal chimneys can be divided into two groups:

- heat-insulated pipes – “sandwich”;

- “Hot pipes” without insulation.

On the use of “hot” pipes in a brick mine, see above. “Sandwich” -constructions consist of two pipes laid with a special fire-resistant heat-insulating layer. The inner tube is made of high-quality stainless steel, able to withstand the effects of high temperatures and aggressive chemical compounds.

Thermally insulated modular chimneys

Non-combustible materials that have low thermal conductivity and do not emit vapors and gases hazardous to humans under the influence of high temperatures are used as thermal insulation. A set of various elements “sandwich” -tube allows you to mount the desired size of the chimney for the fireplace. Customized manufacturing of heat-insulated pipes for specific real estate is also practiced..

We use refractory ceramics

Chimneys made of chamotte ceramic pipes enclosed in shells made of stainless steel or lightweight concrete have appeared on the domestic market relatively recently. They are produced in Germany under the brand name Shiedel. This German chimney system is a separate, ready for installation, elements, as well as all other consumables necessary for the installation of a vertical chimney.

The outer shell of the structural elements is equipped with ventilation channels, allowing to reduce the temperature on the surface of the chimney. They also provide channels that allow you to install internal mounts, which increases the stability of separately located structures.

Chimneys Shiedel

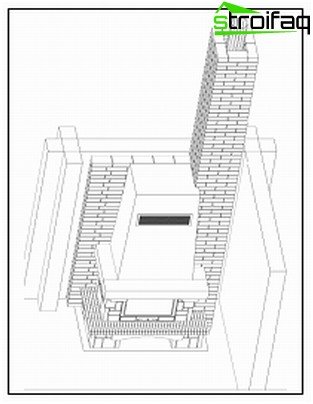

Fireplace Chimney Layout: Shiedel UNI

1. The inner tube having a round shape is made of fire-resistant high-quality fireclay. This material has a high density and strength, and is also resistant to acids. Elements of the inner pipe are connected with a special refractory mastic, which ensures the tightness of the smoke channel.

2. To fix the elements of the outer shell apply a solution made on a cement-sand base.

3. A set of chimney systems includes:

- modules for mounting the entire structure;

- fastening elements to the roof;

- elements connecting the chimney to the fireplace;

- decorative decoration of the headband and the roof part of the chimney.

Ceramic chimneys SCHIEDEL

Important! These systems are ideal for wooden buildings because they have effective thermal insulation. Installation near combustible structures of the house is possible with a five-centimeter indent from them.

Spectacular glass chimneys

In the modern market there are, albeit in limited quantities, other “exotic” materials for the installation of the chimney. Such materials include glass. The advantages of glass chimneys include:

- lack of corrosion;

- moisture resistance;

- low thermal inertness.

Glass hanging chimneys

However, these structures are very expensive in themselves, as well as their installation is associated with high material costs. Perhaps in the near future glass chimneys will be able to displace other materials from the market. While they account for a very small percentage of sales.

Important! It is strictly forbidden to use asbestos-cement pipes for the installation of the chimney. This material is carcinogenic and fire hazard..

Conditions for the normal operation of the chimney

Operation of the fireplace will not be a hassle if during installation all the conditions ensuring the normal operation of the chimney are taken into account. It is necessary to ensure the speed of advancement of gases for open furnaces and sufficient vacuum for closed ones. The height of the chimney flue cannot be lower than 5.5 meters, counting from the combustion surface. It is very important to maintain the relationship between the area and cross-sectional shape of the smoke channel, its height and the overall parameters of the fireplace insert.

Mistakes made can spoil the charm of having a fireplace. It can turn into just a decorative element of the interior, which cannot be used for its intended purpose. Therefore, if you want to install a fireplace in your home, you need to contact the professionals who have a name in this market segment.