Gas heating boilers

Gas boilers heating – devices that transfer energy to the coolant that occurs during the combustion of fuel. The boiler can be called the heart of the heating system and the main tool for heating apartments and cottages. There are several varieties of heating boilers, but gas ones are the most common, because they are a reliable and economical way to create comfortable conditions in your home.

Content

- Advantages and disadvantages of gas equipment

- The advantages of gas heating systems

- Cons of gas boilers

Advantages and disadvantages of gas equipment

Gas boilers are today considered the most popular equipment used where the gas pipeline is laid..

The advantages of gas heating systems

- a gas heating boiler allows you to heat objects and rooms of impressive size;

- the efficiency of gas boilers is extremely high, and the price of fuel is low. In addition, the boiler gives up much more energy than it consumes;

- there is no need to monitor the flame, gas is supplied to the installation continuously. If, for any reason, the flame goes out, the sensor will immediately inform the electric ignition system about this, and the supply of a spark will light the burner again;

- gas boilers are easy to operate, have high efficiency and are designed for a long service life.

Cons of gas boilers

- gas boiler installation involves compliance with many conditions relating to both the technical side and the preparation of relevant documentation. It is necessary to coordinate their actions with Gaztekhnadzor, for which a project, an agreement with the installation organization, a copy of the organization’s license to carry out activities of this kind should be provided;

- it is necessary to take care of the presence of a chimney for the removal of waste substances. Installation must be carried out in a well-ventilated room with a separate exit to the street. This is especially important for boilers with an atmospheric burner;

- when the pressure in the gas system decreases or when the burner is worn out, the boiler starts to smoke, its efficiency decreases;

- with an area of less than 100 m2, the use of a gas boiler becomes not only economically disadvantageous, but also dangerous;

- requires the installation of automation that monitors gas leakage.

Location classification

The classification of gas boilers for heating is extensive. By type of placement, they are wall and floor.

Wall mounted gas boilers

This type of heating equipment appeared relatively recently, but has already managed to gain a lot of fans. The wall-mounted gas heating boiler is also called a mini-boiler. And this is no coincidence: in a small case, not only a heat exchanger, a burner and a control device are hidden, but also circulation pumps, a security system, an expansion tank, a thermometer, a manometer and other components.

Despite the fact that these boilers incorporate all the most advanced technologies, their cost is much lower compared to outdoor counterparts. Another major benefit is ease of installation. Many buyers think that ease of installation is a feature that should be of interest only to installers. This is a big mistake. After all, the amount that will have to be paid for installing the boiler with components mounted separately will be quite substantial. Compactness, the ability to organically fit a gas boiler into the interior is another advantage of wall-mounted installations.

Wall-mounted boiler – lightweight, compact but power limited system

According to the method of exhaust gas removal, boilers are divided into samples with forced and natural draft. In the first case, the decay products are removed using the built-in fan, in the second – due to the draft of the chimney. Most manufacturers produce boilers of both the first and second types. Boilers with natural draft are familiar to many: the chimney above the roof is hardly able to surprise. But boilers with forced draft can be called a novelty, because they appeared not so long ago. Such models are good for rooms without a chimney, i.e. waste substances are discharged through a coaxial chimney, for which you need to make a hole in the wall.

You need to know! Coaxial chimney is also called “pipe in pipe”. Combustion products are discharged into the street through the inner pipe, and air enters through the outer pipe.

Forced draft boilers do not require fresh air to maintain combustion, do not burn oxygen from the room and save on installation costs. According to the type of ignition, wall-mounted boilers are divided into electric and piezoelectric ignition. The first ones are more economical, because ignitor with a continuously burning flame is absent, which reduces gas consumption. Another advantage is the automatic resumption of operation in the event of a power outage, while the piezo ignition model must be manually switched on..

By type of burner, wall-mounted boilers are divided into conventional and modulating burners. This burner provides an economical mode, as the boiler regulates the power independently depending on the heat demand.

You need to know! The modulation burner will provide the most comfortable conditions in the DHW (hot water) mode, maintaining the water temperature at a given level.

In most cases, wall-mounted gas boilers are equipped with devices that guarantee safe operation. A flame detector shuts off the fuel supply when a flame enters, a blocking thermostat turns off the boiler when there is an emergency temperature rise, a special device blocks the gas installation in the event of a power failure, etc..

Wall mounted boilers are used in two directions:

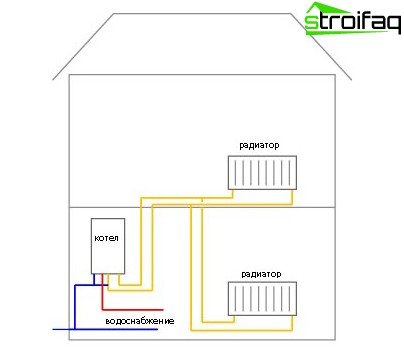

Scheme of including a gas boiler in the heating circuit of an autonomous house

1. Creating an individual heating system in cottages and country houses. The power of the devices varies from 12-42 kW, which means that the range of rooms that can be heated efficiently is quite wide (50-400 m2). Ease of installation, low cost and compactness are factors contributing to the increase in the popularity of such boilers.

2. Apartment heating in multi-storey buildings. Having his own boiler, the owner decides when and what temperature to create. Now, situations when heating is turned on ahead of time or, conversely, late, are not terrible.

Floor gas installations

The floor gas boiler is a traditional device that has not undergone drastic changes for many years. The heat exchanger is usually made of steel or cast iron. The debate about which material is better to stop, perhaps, never. On the one hand, the cast-iron heat exchanger is less susceptible to corrosion, but it is brittle, and, therefore, the risk of microcracks during loading, unloading and transportation is quite large. In addition, the use of hard water over time leads to the destruction of the heat exchanger. Steel boilers are much lighter than cast-iron, but, if operating rules are not followed, corrosion may occur.

You need to know! By and large, creating the right conditions for the operation of a steel boiler is simple. The main thing is to ensure that the temperature does not fall below the “dew point”.

Floor gas boilers with supercharged (replaceable fans) and atmospheric burners are isolated. The first – have higher efficiency and higher cost. The second ones are cheaper, and they work much quieter. The atmospheric burner is an integral part of the boiler, i.e. included in the price.

A supercharged burner is not included in the package and is sold separately. The power of boilers with an atmospheric burner ranges from 10 to 80 kW, while boilers with replaceable inflatable burners show a power of several thousand kW. This allows each consumer to choose the best heating option for themselves..

Floor boiler: a powerful unit that copes with the supply of water to heating and water systems

Another important factor is the dependence of equipment on the mains. Problems with the supply of electricity are not uncommon, which creates the prerequisites for finding the best options for creating a comfortable environment. Speaking about Russian manufacturers, it is worth noting that the issue of power outages, when releasing products, is taken into account. As for manufacturers of imported boiler plants, there are 2 ways to achieve autonomy:

1. Simplification of the boiler control system due to the lack of automation. In this situation, the boiler can only maintain the temperature of the water, not focusing on the temperature of the air in the room.

2. The use of a heat generator that generates electricity, necessary for the functioning of automation, from heat.

Feature Division

By functionality, all gas boilers are divided into single-circuit and double-circuit.

Single-circuit gas boilers

A single-circuit boiler performs a single function – heating the coolant

A gas single-circuit boiler (single-stage) heats only the water in the heating system. To use such a boiler for domestic hot water, you must buy an indirect heating boiler. When buying a boiler, pay attention to the fact that the volume of the chamber must correspond to the number of people living in the house.

Dual circuit units

The gas double-circuit boiler (two-stage) is more functional and is equipped with an additional built-in hot water burner. Such a boiler serves both for hot water and for heating..

You need to know! Although the cost of a double-circuit boiler is less than the total price of a boiler and a single-circuit boiler, it is not able to guarantee convenient use of hot water to more than three residents.

The double-circuit boiler switches to heating immediately after you open the faucet in the bathroom. When the taps are closed, the water cools. If hot water has not been used for several hours, then when you open the tap, cold water will flow from it. The greater the distance between the water intake point and the boiler, and the larger the diameter of the pipe connecting them, the longer it will take to wait for cold water to change to warm, which means that the more water will be wasted.

You need to know! The length of the pipe connecting the boiler to the most distant intake area should not exceed 7 meters.

It should be noted that the heat exchanger of such a boiler is especially susceptible to scale formation due to the deposition of mineral compounds. Scale makes heat exchange difficult, and this leads to a decrease in the productivity of the water heater and the consumption of more fuel.

The dual-circuit boiler is multifunctional, if desired, their capabilities can be expanded by connecting additional modules

By the method of combustion taps, gas double-circuit heating boilers are chimney (remove decay products through the pipe), condensation (condensate is removed through the chimney, requiring complete sealing) and turbocharged (the chimney is equipped with a fan).

How to choose a gas boiler

The question of how to choose a gas boiler is of concern to many. I would like to buy reliable and high-quality equipment that will last for more than one year. You can, of course, search for “the best gas boilers” or “gas boilers: reviews”, but this is unlikely to solve the problem. Choosing a gas boiler – a process that requires an individual approach.

Priority should be given to the power that you want from the boiler. This value is laid with the focus on the most energy-intensive heat consumer – the heating system.

You need to know! To determine the power, you can use a simple ratio: to heat 10 m2 you need 1 kW of power. For example, the area of a private house is 300 m2, which means you need a boiler with a capacity of at least 30 kW.

Want to get hot water along with heating? Choose a wall-mounted gas boiler, which is inexpensive and easy to install. Do not want to carry out maintenance every year? Then take a look at the outdoor boiler. It is, of course, more expensive, but the annual inspection, unlike the wall, does not require.

Installing a gas boiler is a complex process, it is recommended to trust it to professionals

Speaking about manufacturers, it should be noted that the choice, of course, is yours. We can only say that domestic firms are doing pretty well with the production of high-quality heating equipment, which does not differ in functionality from boilers of foreign manufacture, but costs, incidentally, an order of magnitude cheaper.

The heat in the house is an important component of comfort and coziness, so the choice of a gas boiler (the most profitable heating means today) requires a competent and responsible approach. Weigh the pros and cons, and then go shopping. If nevertheless doubts do not leave you, contact the specialists who will select the best option for you..