Installation and installation of gas boilers

The problem of the lack of hot water supply or central heating, as well as the poor quality of these services, is successfully solved by the installation gas boilers. For this, there are two types of boilers: single-circuit and double-circuit. A single-circuit gas boiler can provide only one process, for example, heating. Double-circuit – both processes: both space heating and domestic water heating.

Content

- Rules for installing gas boilers

- Requirements for the installation of gas units

- Installation of a wall gas boiler

- Chimney design

Not only is the installation of a gas boiler in itself a very laborious and troublesome task, in order to produce it, it is necessary to observe certain standards for installing gas boilers. The operation of any gas appliances is always fraught with risks, which is why there are fire safety rules.

Rules for installing gas boilers

Before installing the boiler in a private house, it is necessary to prepare some documents and perform certain actions. What is required:

- Natural gas supply contract for an individual developer;

- The technical specifications and the gas equipment installation project must be agreed with the local representative of the gas service. Project documentation is most often developed by specialized institutes with the appropriate license for this type of activity: gorgaz, raigaz, oblgaz, mingaz, etc .;

- Installation of gas equipment should be carried out by the installation organization;

- An engineer of a district or regional gas organization must come to the facility and check the correct connection of gas in the furnace and kitchen, their compliance with the requirements. If all the norms are met, he must issue a conclusion on the basis of which it is possible to open the gas “valve” leading to the boiler;

- The heating system must be pressurized to P = 1.8 atm (see on the boiler pressure gauge);

- Decontaminate the heating system;

- Check all connections for leaks;

- It is imperative to install a voltage stabilizer for the boiler and preferably an uninterruptible power supply;

- Do not add antifreeze to warming water. This may damage the gaskets and lead to leaks in the heating system..

Gas boilers must be installed using special technology to ensure the safe operation of explosive units emitting toxins in the event of a leak

The room in which the boiler will be located must meet certain requirements. When installing a heating boiler in a private single-family house, a furnace or, as it is also called, a boiler room, can be equipped on any floor, including in the basement, basement and even the attic or roof. Restrictions apply to residential premises, a bathroom and a bathroom; it is forbidden to place a boiler in them.

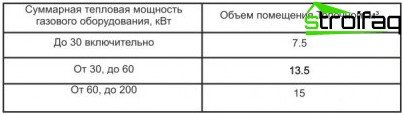

To calculate the volume of the boiler room, the total heat output of the heating equipment, flow or tank water heaters is taken into account.

Important! Please note that in the technical passport for gas equipment, the room with the boiler should be called – furnace or boiler room.

A table of the required boiler room volume is given below:

Table of the required boiler room volume depending on the boiler capacity

There are exceptions: if a heating boiler with a closed combustion chamber, the volume of the boiler room is not standardized, and the presence of a window with an exit to the outside is not necessary.

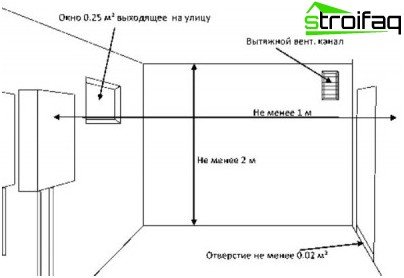

To supply and exhaust air, it is necessary to ensure the inflow of the required volume. To ensure 23.3 kW of boiler power, 2.5 m3 / h of gas must be burned. For complete combustion of this volume, 30 m3 / hour of air is required. If insufficient air is supplied, the gas does not burn completely, resulting in the formation of an extremely harmful substance, the inhalation of which negatively affects human health. If you inhale it for 15 minutes, death occurs. Air should flow not only from the outside, but also flow from other rooms of the house. This is ensured by the presence of a gap between the door and the floor and a hole with a grill in the doors.

The heating boiler is installed on the floor at a distance of 10 cm from the wall, which should be made of non-combustible material. If there are no walls made of non-combustible materials, then protection from refractory material can be installed.

Requirements for the installation of gas units

Without certain requirements, the gas service will not give permission to connect the boiler to the main. But compliance with these requirements and norms is dictated not so much by the bureaucracy as by bitter experience and fire safety. Restrictions are imposed not only on gas equipment and its installation, but also on the room in which the boiler will be located.

Normative requirements for the installation of a gas boiler

- The area of the room in which the boiler will be located should be at least 4 m2, the ceilings should be higher than 2.5 m;

- The width of the door leading to the room should be at least 80cm;

- The boiler must be naturally lit through the window opening. For every 10 m2 of the room there should be at least 0.3 m2 of window;

- Good ventilation is mandatory, since the combustion of gas in the boiler is ensured by the flow of oxygen. The area of the hole to ensure the influx of outdoor air should be 8 cm2 for every 1 kW of boiler power;

- Gas pipes must be made of metal only. Flexible hoses can only be used to connect consumers;

- The cross section of the chimney must correspond to the capacity of the boiler. If the boiler power is 30 kW, the diameter of the chimney should be 130 mm. If the boiler power is 40 kW, the diameter of the chimney is 170 mm;

- It must not be allowed that the cross-sectional area of the chimney is less than the cross-sectional area of the hole for connecting the chimney;

- The upper end of the chimney should be displayed at least 0.5 m above the roof ridge;

- The boiler’s power supply system must have a special machine with configured current and thermal protection;

- In the room where the boiler will be, there should be a gas analyzer, which will warn about a gas leak, and an electric valve that shuts off the gas supply;

- Gas equipment can be located in the basement of only a single-family private house. In multi-storey apartment buildings installation of gas heating boilers in the basement is prohibited.

- Each device must be equipped with a gas meter;

- Ventilation should be installed in the upper part of the room..

More detailed information on all requirements and standards can be found in the documents: SNiPe II-35-76 “Boiler units”, Code of practice for designing autonomous heat supply systems SP-41-104-2000.

Installation of a wall gas boiler

A wall-mounted gas boiler is installed if the power requirements are not too large and there is not much free space. Most often, such boilers are used for heating and water heating in multi-storey buildings. The predecessor of a gas wall-mounted boiler is gas water heater, which provided heating water for domestic needs in the “Khrushchev”.

Installation of a wall gas boiler

The installation of wall-mounted gas boilers makes it possible to equip a house with central heating with an autonomous system of additional heating. Gas must be supplied and the premises must comply with the requirements and standards..

Gas units are installed in special rooms – furnace, having ventilation openings for the inflow of air mass and the removal of combustion products. The boilers are not demanding on free space and can be installed on top of another appliance standing on the floor. You can install wall-mounted boilers in cascade. It is very convenient if you need more power, several boilers turn on at once.

Several boilers in one furnace – a convenient option

Installation of a gas boiler is carried out at a distance of 20 cm from other gas appliances and flammable materials. Depending on the capacity and model of the boiler, the distance between it and the wall can be from 30 to 50 cm. It is undesirable to place the boiler in the opening between the walls or in the immediate vicinity of the window. The power source should be close enough.

After the place for the boiler is selected and approved, it is necessary to check the purchased boiler for a complete set. The box should contain instructions, wall brackets, mounting template and mounting hardware. It is advisable to compare the technical specifications indicated on the packaging with those indicated on the identification plate located on the inside of the front cover..

Before installing the boiler in place, it is necessary to flush with water all the pipes of the boiler and the entire system. This is necessary in order to remove foreign particles that could get into the unit during assembly at the factory.

The slats on which the boiler will be mounted are nailed at a distance of 0.8-1.6 m from the floor.

Important! The wall should be vertically flat and strong enough to support the weight of not only the boiler, but also related equipment. If the wall is made of combustible material, you can attach a gasket of non-combustible material to it, the thickness of which should be at least 3 mm. The boiler in this case must be fixed at a distance of 4.5 cm from the wall.

The boiler is fixed on the slats. Before connecting the boiler to the water pipes, it is necessary to remove the plugs installed on the corresponding pipes.

To prevent clogging of the boiler heat exchanger, it is advisable to install a mesh angle filter at the water inlet. Ball valves are installed on both sides of the filter, this will facilitate future maintenance and repair..

Then it is necessary to check whether the boiler hangs evenly. Swing in any direction can lead to unpleasant consequences.

The connection of gas pipes to the boiler must be done only with a metal pipe, a rigid connection, through the “American” or a special squeegee. Use a paronite gasket.

This completes the installation of the boiler with your own hands. Direct connection of the gas boiler is carried out only by authorized persons after checking compliance with all requirements and standards.

Chimney design

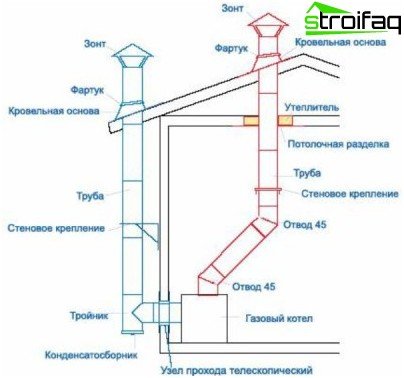

The material for the chimney is selected depending on the combustible fuel and the type of boiler. For a gas boiler, the pipes should be cylindrical and made of metal, preferably stainless steel. Such chimneys are the safest, most durable and reliable..

The chimney is discharged above the ridge of the house. A hatch must be mounted for cleaning the chimney. In order to ensure the convenience of collecting soot during cleaning, collection and removal of condensate, an empty space is required under the entrance of the chimney.

The scheme of the chimney of a gas boiler

When installing the chimney, there should be no more than three elbows and turns. The pipe connecting the boiler and the chimney should be as short as possible, not more than 25 cm.

The vertical section at the outlet of the boiler must be equal to at least two diameters. Behind this vertical section, the pipe of the connecting section must necessarily rise upward with a slope towards the boiler.

In this case, smoke removal is carried out due to natural draft through the chimney.

Following all the requirements and rules for installing gas boilers will ensure their efficient operation, durability and fire safety.