Design of gas supply systems and networks

The decision to supply gas to a private house is justified by sound economic considerations, since it is the cheapest, therefore, the most popular type of fuel. If you want to implement a gasification project, you should know that a mandatory step on the road to achieving the goal will be to design the gas supply necessary to ensure safe operation and to connect an autonomous residential facility to centralized networks or to an autonomous gas tank. The right to carry out design work on the creation of gas supply systems is owned only by licensed executing companies. However, the customer will not be disturbed by information about design rules for control and for choosing a rational scheme.

Content

- What to consider when designing?

- The specifics of creating gasification projects

- Types of outdoor gas pipelines

What to consider when designing?

This type of fuel belongs to the category of flammable explosive substances. The slightest deviations from the dictates of building codes may end in tragedy. In addition, the gas is toxic and harmful to the environment. All these nuances must be taken into account by the designer. The owner of the house should know that it is best to order a project during the construction of the house, since for the gas heating device it is necessary to allocate a special room for the boiler room, provide effective ventilation and completely secure the use.

Gas supply design must be carried out by professional designers, since the substance transported and processed by the boiler is classified as flammable and explosive

The specifics of creating gasification projects

Even the designer cannot preliminary name the cost of the final result. The amount depends on the mass of criteria, including the principle of wiring, the width of the pipes, the number of stages of fuel pressure, the number of bends, the selected materials and equipment. Definitely, you will have to pay for the design of gas supply systems, including:

- creation of a project for the supply of natural fuel from a centralized gas pipeline to a house;

- development of a project for the internal wiring of the gas network.

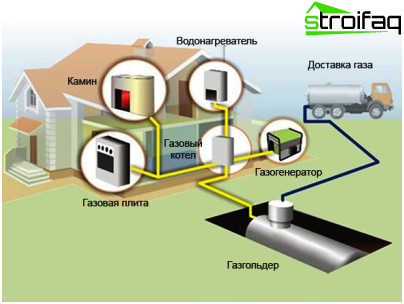

Designing gas supply systems for a private house includes creating a project for supplying fuel to the building and developing a project for internal wiring

You will also need to pay for installation, for pipes, units, fittings intended for installation.

Types of outdoor gas pipelines

There are two ways to lay the gas supply to the house. The pipeline is carried out underground or without expensive excavation work, laying it openly.

- The construction of an underground gas pipeline will cost approximately 1.5 times more than laying above ground. However, the pipes will be much better protected from external mechanical and atmospheric negativity. Underground systems are much more reliable and safer, but in case of damage, finding and eliminating the cause will be more difficult and more expensive..

The underground method of laying a gas supply network is more expensive, but from a safety point of view, it is significantly ahead of the construction of facilities for introducing fuel above the ground

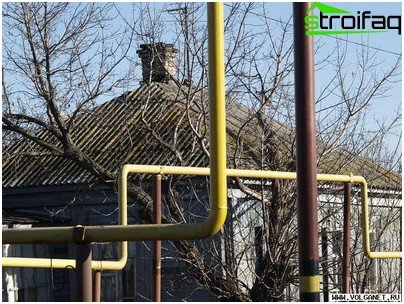

- The construction of an elevated network is cheaper, but corrosion will threaten open sections of gas pipelines, it is easier to connect to them without permission, they are more dangerous for the environment.

Pipes laid in an open way are subject to corrosion, it is easier to connect to them without the consent of the owners

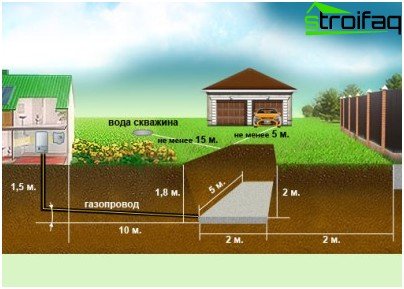

Not always preferences in the choice of above-ground or the opposite way affect only price factors. There are conditions independent of the wishes of customers, these are:

- values of soil corrosion activity that do not meet the requirements of GOSTs, excluding underground laying;

- the proximity of the high-voltage power line, because of which it will be necessary to choose the construction of an underground gas pipeline inlet;

- lack of consent of neighbors if part of the underground pipeline crosses their section;

- the atmospheric temperature recorded in the region is lower – 45 ?, due to which pipes can only be laid underground;

- the intersection of major highways, the restoration of the integrity of which cannot be classified as cheap events, moreover, during the installation period, even not too “busy” roads will need to be blocked with obtaining permits from the transport inspection services.

Construction norms for the location of an autonomous gas tank

Often, the project of supplying a gas pipeline to a house is a combined version combining both laying methods. What the designer chooses depends on the specific circumstances and the exact characteristics of the site.

Specifics of designing internal networks

The calculation and design of gas supply for a private house is again based on purely individual factors, based on which a boiler of a certain type and power is selected, additional equipment, a wiring diagram is designed. However, there are requirements common to all projects, compliance with which is a prerequisite for gasification.

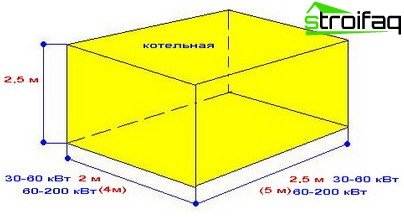

- Mandatory presence of a boiler room for the installation of a gas unit, since it is prohibited to place it in residential premises. Should a minimum of 4 m be allocated to one boiler? in a room with a ceiling height of at least 2.2 m. The furnace doorway should be 0.8 m wide, as large as possible. The size of the windows is calculated on the basis of 0.3 m relying on 10 cubic meters of the room. The furnace should be finished with non-combustible materials.

A prerequisite for gasification is the presence of a furnace (boiler), equipped in accordance with strict safety requirements regulations

- The boiler room should have a power grid, sewer, gas and water pipelines. For the safety of electrical communications, it is necessary to provide grounding. Water is supplied for the installation of heating and domestic hot water systems; sewage is needed to ensure emergency runoff. The gas line must have a separate shut-off unit for each of the boilers.

In the boiler room, all communications necessary for the connection and functionality of the boiler equipment must be carried out

- The furnace room should have an exit to the general ventilation system of the building and two additional channels for the chimney. One of the additional channels is designed to install the chimney itself, the second – for cleaning it. For units with a natural chimney, a ventilation grill is required, through which fresh air will flow from the street.

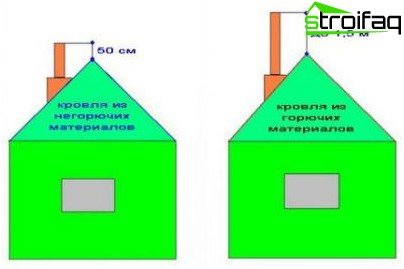

- The chimney must be made of gas-tight materials. The upper plane of the chimney cut is installed above the roof. The height of the pipe section protruding above the roof depends on the degree of flammability of the roofing material.

Designing gas supply for a private house: the rules of the device for the removal of combustion products – the height of the chimney pipe

- The main unit of the system – the boiler is located away from endangering sources of open fire. On all sides, a free approach must be ensured..

There is no need to organize natural draft if the boiler is able to forcibly remove combustion products, which is carried out by a fan mounted in a pipe above the roof ridge. Usually these are double, the so-called coaxial chimneys, consisting of two pipes with different diameters. Through the external annular channel of the coaxial chimney, air flows from the street into the room, while simultaneously warming up due to the thermal energy of the flue gases that are discharged outside. This design allows you to reduce fuel consumption, increasing the efficiency of the gas unit.

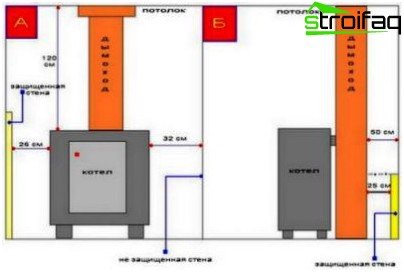

Rules for installing boilers: A. From the boiler to the surface of the unprotected ceiling, the distance is 1.2 m, from the side plane to the unprotected wall 0.32 m, to the wall with a metal sheet on asbestos cardboard the distance can be 0.26 m or more. B. From the chimney to the combustible structure, a distance of at least 0.5 m, if the wall is faced with asbestos metal sheet, the boiler can be installed at a distance of 0.25 cm.

Of course, the installation of a system transporting an explosive toxic substance, as well as the design of gas supply networks, must be entrusted to professionals. The risk of amateurish mistakes is too great and catastrophic. However, knowing the intricacies of organizing gasification, it will be much easier to identify the mistakes of dishonest performers, and the timely elimination of defects will ensure flawless operation.