Do-it-yourself pyrolysis boiler

The problem of heating in the absence of cheap electricity and coal, as a rule, is solved with the help of firewood. Due to the rise in price of such a natural resource as natural gas, its use can significantly affect the family budget. People who are faced with the gasification of their private homes begin to look for alternative sources of heat. And a do-it-yourself pyrolysis boiler comes to the rescue, made from available materials – a wood-fired boiler that runs on the cheapest type of fuel.

Content

- Concept and design of a pyrolysis boiler

- The principle of operation of the gas boiler

- Wood-fired boiler – main advantages

- What is the efficiency of a pyrolysis boiler

- About fuel for gas boiler

Concept and design of a pyrolysis boiler

The pyrolysis boiler is designed for heating various rooms by burning wood – pressed briquettes, logs and waste. In its design, the gas boiler is different from the classic solid fuel equipment, which also burns firewood. Why it is advantageous to install a pyrolysis boiler: the principle of operation will help to figure it out!

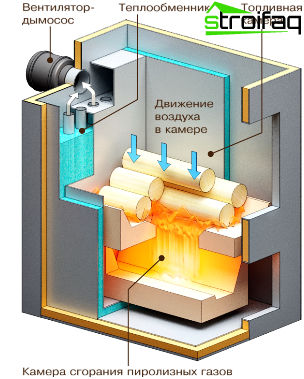

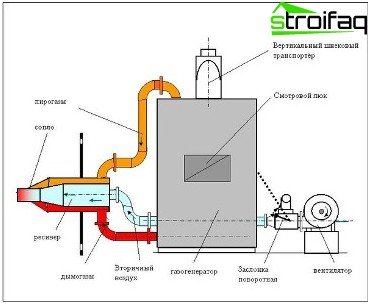

The structural scheme and principle of operation of the pyrolysis boiler

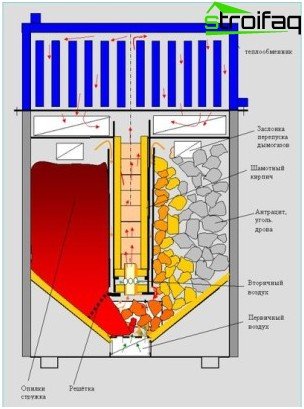

The furnace in pyrolysis boilers is divided into two parts. In the gasification chamber or the loading chamber (first part), when there is a lack of oxygen, firewood burns and pyrolyzes, and the gases released burn out in the combustion chamber (second part), into which secondary air is supplied. The heat removal from the loading chamber is minimized..

These spaces are separated by the grid-iron on which briquettes are located. Primary air passes through a layer of wood from top to bottom. Thus, the main difference between gas-generating boilers from other household appliances is considered to be upper blast.

Fire chambers of such structures are characterized by increased aerodynamic drag, so in most cases their draft is forced. Sometimes it is realized for technological reasons using a smoke exhaust, and not due to a blower fan, which is more typical for small boilers.

The principle of operation of the gas boiler

The functioning of the wood boiler is based on the principle of thermal decomposition of wood, the essence of which lies in the fact that dry wood can decompose into solid residue (coal) and volatile part (gas) under the influence of external factors.

How does a pyrolysis boiler work?

During the process that occurs in the loading chamber under the condition of high temperature and lack of oxygen, generator gas is released from the resource. Wood gas passes through a nozzle, mixing with secondary air and burning in a chamber at a temperature close to 1200 degrees Celsius. The flue gases pass through the convective part of the heat exchanger, giving their heat to the working fluid, and then are removed through the chimney.

The pyrolysis boiler loading and burning chamber has a refractory lining, which significantly increases the temperature inside the apparatus and creates ideal conditions for efficient and high-quality burning of firewood.

Wood-fired boiler – main advantages

Today, different devices are used for burning wood: heat-storage stoves, air and water boilers. Of all the equipment, pyrolysis (gas-generating) boilers are of most interest to consumers. The main difference between pyrolysis boilers and simple solid fuel models is the fact that they burn not the firewood itself, but also the resulting wood gas. During burning, no soot is formed at all, and ash appears in a minimal amount, so the apparatus needs less cleaning.

The indisputable advantage of a pyrolysis boiler is its ability to maintain a given temperature longer than traditional boilers can, due to its higher efficiency and increased loading chamber. Some designs on the same fuel tab can work during the day.

The pyrolysis boiler needs less cleaning

There are fewer carcinogens in the exhaust gas. During combustion, the pyrolysis gas interacts with active carbon, so the flue gases at the outlet are mostly a mixture of water vapor and carbon dioxide..

Another advantage of gas-generating boilers is the ability to regulate power – 30 – 100%. Pyrolysis apparatus is able to utilize some waste, almost without polluting the environment. Such wastes include rubber, plastics and polymers. But at the same time, wood-fired boilers are demanding on fuel, need power supply and have large dimensions.

What is the efficiency of a pyrolysis boiler

The operation time of a wood-fired boiler is measured over a wide range depending on many factors – outdoor temperature, desired room temperature, home insulation, humidity and type of fuel, and accuracy of heating system design. But one thing is certain – gas-generating boilers are much more efficient than traditional ones.

Rubber and polymers can be disposed of in a pyrolysis boiler furnace without harming the atmosphere

When burning wood, including wet, it is not possible to achieve such high temperatures as when burning wood gas obtained from them. In addition, less secondary air is required for gas combustion, due to which the temperature rises, and therefore the time and efficiency of combustion increase. In addition, the pyrolysis gas combustion process is easier to control..

About fuel for gas boiler

For combustion, wood is used, which has a length of 380 – 450 millimeters and a diameter of 100 to 250 millimeters. Fuel briquettes should have such a size – 30 by 300 millimeters. Small wood waste and sawdust can be burned simultaneously with firewood, but it costs no more than 30% of the volume of the loading chamber. Such boilers can burn wood, which is characterized by humidity up to 40%.

Fuel for a pyrolysis boiler

Pyrolysis boilers should be heated with drier wood, only in this case the unit will operate at maximum power, and the service life will increase. Wood with a 20% moisture content is characterized by a calorific value of 4 kW per hour per kilogram of wood, wood with a 50% water content is characterized by a calorific value of 2 kW per hour per kilogram of firewood.

Thus, the calorific value of the fuel depends on the presence of water in the wood: the useful energy content of the briquettes decreases significantly with increasing water content. At the same time, fuel consumption doubles.

We make a pyrolysis boiler with our own hands

Boilers with pyrolysis burning of firewood have recently become more popular, because the dependence on unstable tariffs for natural gas is removed. Of course, there are good gas generating devices on the market with good characteristics, but their cost is still quite high, which confuses buyers. At the last construction exhibition, a simple domestic-made boiler cost at least one thousand dollars. That is why many consumers prefer to make pyrolysis boilers with their own hands..

Tool for work

To independently make a wood-fired boiler, it is enough to have the desire and the necessary tool! Of course, you will have to spend a lot of effort. But anything is possible.

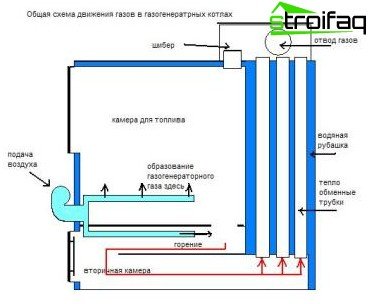

The scheme of movement of wood gas in the boiler

To begin with, it is worth collecting a maximum of information about this heating device and its features. It is necessary to calculate and decide in advance which type of combustion will be optimal for a particular building – on grate or with a slot burner. Then you should visit a specialized store and purchase the necessary parts. To make a pyrolysis boiler, you need such materials:

- 4 mm thick steel pipe;

- 4 mm steel sheet;

- several profile pipes;

- electrodes

- 20 mm round rod;

- centrifugal fan;

- fireclay bricks;

- automation that controls the temperature;

- nuts and bolts;

- asbestos cord.

Drawings and schemes of gas boiler

The exact amount of material can be calculated based on the drawings. On the Internet on this subject there are many paid drawings and literature. If you are guided by this material, you will get a tolerable unit. The pyrolysis boiler scheme is needed to indicate the firebox, heat exchanger and the place of water supply. Do not strive to create a diagram of the apparatus on wood from scratch, it is better to use the circuit diagram and make only some adjustments and changes to it.

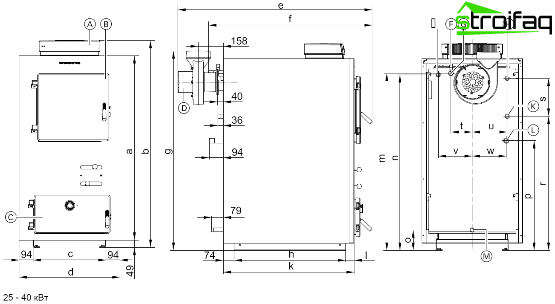

Wood pyrolysis boiler drawing

By making a gas-generating boiler with your own hands, you can take the 40 kW heating apparatus diagram as a basis, which was developed by designer Belyaev, and then optimize it for laser cutting with fewer parts used. You can change the design of the device so that its internal volume remains unchanged.

At the same time, it is desirable that the jacket of the heat exchanger increase significantly. Next, you need to connect all the details of the future pyrolysis boiler, clearly following the drawing. In this case, air is used as a heat carrier, and it can warm the room without heat loss..

It is not necessary to ensure the tightness of the pipes, because for a boiler on wood, leaks and the possibility of freezing of the heating system are uncharacteristic. Thus, this device is considered an ideal solution for installation in a country house, where it is to be heated only occasionally.

Schematic diagram of a pyrolysis boiler

After collecting the boiler according to the scheme, you can proceed with its installation and further tests. A properly made gas boiler must quickly reach the required mode, and the heating system must warm up in a maximum of thirty minutes. The temperature in the room usually rises very quickly..

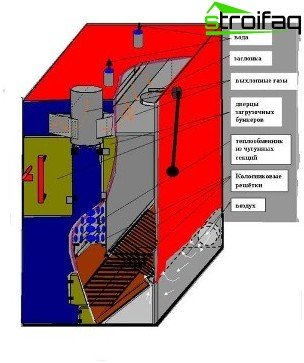

Advantages of the Blago pyrolysis boiler

The Blago boiler was developed by the inventor Blagodarov Yu.P., who declared the advantages of his creation. By the duration of burning wood at maximum calorific value, the gas-generating apparatus Blago is superior to other boilers.

In this model, grate bars completely cover the bottom of the fuel bunkers. Therefore, with natural traction, there is a high heat of combustion of the fuel and a longer burning period due to the layout of the fuel bunkers, which makes it possible to increase the volume of fuel bunkers without causing damage to the efficiency.

Blago boiler design

The pyrolysis boiler device allows fuel to burn in one of the two combustion chambers, and in the third to burn. The Blago is non-volatile and always delivers the required power. The complete combustion of compounds of phenolic groups is carried out – tar, resins, alcohols, essential oils.

Installed rails in the combustion chamber act as good heat sinks. Peat briquettes, sawdust and coal can be burned in a pyrolysis boiler. In the period of low temperatures, it is possible to lay fuel in the combustion chamber constantly, maintaining the optimum temperature in the room.

Thus, despite the fact that the courtyard is the 21st century, people still turn to firewood as a natural resource for heating. Now it’s clear why, of all solid fuel devices, pyrolysis boilers for the population are of the greatest interest.