Long burning pyrolysis boilers

Despite the emergence of new heating methods, residents of Western Europe, the United States, and the CIS, especially those who are unavailable for one reason or another, continue to heat homes with the most affordable fuels – coal, peat or firewood. True, the old stoves were replaced by traditional boilers and pyrolysis boilers – modern and efficient, equipped with automatic control systems. They run on affordable solid fuel, which burns out almost without residue, provide high power and efficiency and are capable of working on one or two downloads for up to 24 hours, provide minimal heat loss.

Content

- The principle of operation, the device pyrolysis boiler

- Fuel for a pyrolysis boiler

- Features of launch and work

- How to choose a pyrolysis boiler

- List of advantages and disadvantages

The principle of operation, the device pyrolysis boiler

Long-burning gas-fired pyrolysis boilers are home laboratories that extract gas from firewood, which is subsequently used for heating. Pyrolysis as a physicochemical exothermic process has long been used in various industries. Its essence is the decomposition of complex organic compounds (oil, coal, wood) at high temperatures and the limited access of oxygen to simple substances – solid, liquid and gaseous.

Thus, a pyrolysis boiler is a two-chamber heating device, in the upper chamber of which at an temperature of 200 to 800 ° C there occurs an exothermic reaction of wood pyrolysis, as a result of which it decomposes into fractions: charcoal and pyrolysis gas, mainly consisting of CO and insignificant amount of CO2. A mixture of pyrolysis gas and air is fed into the lower combustion chamber and, burning at a temperature of 1100-1200 ° C, it emits a very large amount of heat, which is used for heating.

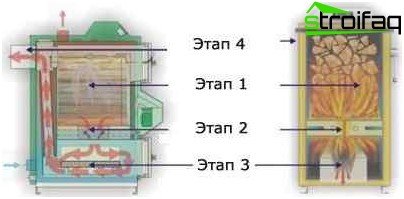

Stages of the pyrolysis boiler

As a result, solid fuel pyrolysis boilers to generate thermal energy actually burn not gas, but gas, providing a high efficiency of 85-90%. Gas combustion, as you know, is easier to control, and this, in turn, allows you to automate the process of controlling the heating system.

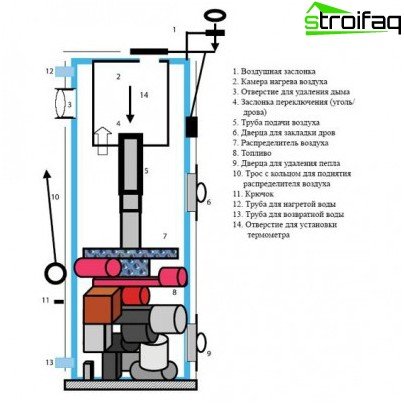

Structurally, the furnace of the pyrolysis boiler is two independent chambers separated by grates. In the upper gasification loading chamber, at high temperature and oxygen deficiency, fuel smolders and pyrolyzes. Heat removal from the upper chamber is prevented by the fuel lying on the grate, through which a weak primary air stream passes from top to bottom.

The device and circuit pyrolysis boiler

The generated gas emitted during the process simultaneously with the secondary air stream enters the lower combustion chamber, the lower part of which is a nozzle made of heat-resistant ceramic – chamotte. The furnaces of this type of heating boilers are characterized by increased aerodynamic drag, and therefore they use forced draft, which is implemented not by a fan, but by a smoke exhaust.

Duration of work gas boiler on one load it depends on the temperature in the street and indoors, the quality of the insulation of the house, the type of fuel and its humidity, the competent design of the heating system, but ceteris paribus, their work is much more effective compared to traditional solid-fuel analogs.

Fuel for a pyrolysis boiler

In practice, solid fuel pyrolysis boilers can efficiently operate on any type of solid fuel, be it wood, peat, brown and black coal. Of course, the duration of complete combustion for each type of fuel is different and it looks like this:

- soft wood – the combustion time is not more than 5 hours;

- solid wood – burning time of about 6 hours;

- brown coal burns out in about 8 hours;

- black coal burns up to 10 hours.

In this regard, the opinion of users is interesting, which is eloquently reflected in their reviews: pyrolysis boilers are most effective when working on dry wood. It is dry firewood with a length of 45-65 cm, the moisture content of which does not exceed 20%, not only provide the maximum power of the boiler, but also extend its service life.

Of course, in the absence of high-quality firewood, any organic fuel with a high yield of volatile fractions is suitable for generating gas in the boiler, provided that it is allowed by the boiler manufacturer:

- wood waste;

- fuel pellets and briquettes;

- some types of peat;

- paper waste from the food industry;

- coal.

Important: Generating pyrolysis gas burns with an almost white flame, practically not emitting by-products of combustion, provided that the selection of primary and secondary air flow rates and fuel humidity not exceeding 20-30%.

If the humidity of the fuel is higher than permissible, the combustion process will be accompanied by the release of a large amount of water vapor, and this is fraught with the formation of soot, tar, a decrease in the calorific value of the pyrolysis gas and even the boiler attenuation.

Features of launch and work

When launching a solid fuel pyrolysis boiler, it is necessary to take into account the features that distinguish it from traditional solid fuel boilers. Everyone understands that the unit operates in the gas generator mode thanks to two chambers equipped with special gate valves-regulators – gates, but not everyone remembers that, unlike traditional boilers, the feed hopper of the pyrolysis boiler should be preheated.

Once the temperature in it, depending on the type of fuel, reaches the optimal 500-800 ° C, you can start loading solid fuel and only then bring the gate into pyrolysis mode and start the smoke exhaust.

A pure yellowish-white flame is evidence of the correct setting of the gas generator and the absence of toxic combustion products in the smoke mixture

With this sequence of actions at start-up, a slow oxygen-free combustion of fuel is ensured, the pyrolysis gas is efficiently released and burned with pure yellowish-white and a constant comfortable temperature is maintained in a heated room throughout the day.

How to choose a pyrolysis boiler

Buying pyrolysis heating boilers, without doubting the effectiveness of their work, can safely be given to those who have the opportunity to buy dry firewood or even dry them in case of excess humidity.

If there is no confidence in such an opportunity, you can choose a modern high-tech heating boiler, the furnace of which combines 80% of highly efficient pyrolysis fuel combustion and 20% of traditional. Modern combined boilers provide high-quality combustion of not only firewood, but also wood waste, peat, coal or any mixture of them with a moisture content of up to 50%.

The combined boiler is equipped with a loading chamber of a very large volume and is capable of burning 80% of the fuel in the pyrolysis mode, and 20% in the mode of a conventional solid fuel boiler

Ceteris paribus, it is recommended to choose a boiler, the volume of the loading chamber of which is capable of accommodating firewood up to 65 cm long. Moreover, both chambers should be covered with high-quality ceramic concrete: it ensures optimal temperature inside the apparatus, high-quality combustion of fuel and protects its walls from burning. A good boiler should provide a fuel burning time of up to 10 hours and serve at least 20 years.

List of advantages and disadvantages

In conclusion, we cite the indisputable “advantages” of gas-generating heating devices and the “minuses” from which the pyrolysis boiler is not yet free – user reviews.

So, the advantages:

- Easy to maintain and in the absence of main gas supply remain the best option for heating.

- Ease of loading: once every 10-15 hours, that is, compared with traditional solid fuel boilers 2 times less.

- High environmental friendliness: fuel burns out almost completely, flue gases contain almost no toxic combustion products, and during the operation of the gas generator, the concentration of CO2 is 3 times lower than the corresponding indicator of a conventional solid fuel boiler.

- A small amount of ash in the furnace and inside the chimney after completion of work facilitates cleaning and subsequent filling of the gas generator.

- Very high heating rate of the coolant, water or air, to a comfortable temperature of 60 ° C.

Disadvantages:

- High cost of gas-generating boilers: 1.5- “times more expensive than traditional solid-fuel analogues.

- All models of pyrolysis heating apparatuses are single-circuit units that do not heat water for domestic purposes.

- Too exacting to fuel: do not work on fuel of the increased humidity.

- Not able to work in full automatic mode: fuel must be loaded manually.

Nevertheless, the high environmental friendliness, efficiency and economy achieved due to complete fuel combustion and scanty heat losses fully compensate for the shortcomings of the pyrolysis gas-generating boilers and the circle of their admirers is steadily expanding..