Electric underfloor heating

Modern electric heated floors are no longer a curiosity and are becoming popular, so to speak, “recognized by the people.” This is to some extent due to the fact that the traditional centralized heating system is characterized by significant shortcomings that are not inherent in the principle of operation of the warm floor. Such a new technique is a familiar element of city apartments, country cottages, its presence in the house clearly indicates a reasonable desire of the owners to create a comfortable home, while rationally spending energy.

Content

- General information about underfloor heating

- Advantages of underfloor heating systems

- Device, principle of operation

- Choice: electric or water?

- Types of electric underfloor heating

- Self-assembly in stages

General information about underfloor heating

Electric underfloor heating is a cable system with a high degree of reliability, it can be used as additional comfortable heating and as a main type of heating system.

Such underfloor heating can be mounted under a traditional coating (ceramic floor tiles, porcelain tiles), and under lighter coatings (carpet, laminate). Typically floors with a power of 150 W / sq. m are installed under the second variant of the indicated floor coverings, and for stronger heating (in the first case), more power is also needed, respectively, heating of such surfaces occurs faster. It should also be noted the fact that underfloor heating with a power above 200 W / sq. m can be installed in homes and not be afraid of excessive energy consumption: thanks to a special thermostat with a temperature sensor, the floor turns off after reaching the set temperature.

Advantages of underfloor heating systems

- easy installation – just put the electric mat in the prepared solution and cover it with floor tiles from above. If there are concerns about the electrical part of the installation, then you can consult an electrician;

- safety of use – installed underfloor heating is almost impossible to damage. In the event of a short circuit or similar problems, the thermostat with a residual current device always monitors the situation and cuts off electricity;

Electric underfloor heating: cable view

- low-cost operation – for example, if the bathroom is 10 square meters. m mat installed with a capacity of 40 watts, the underfloor heating consumes power of only 400 watts. This figure is equivalent to the power consumption of electricity by a large TV or electric blanket;

- the warm floor does not take up extra space (this is an especially relevant parameter in small apartments, where there is nowhere to turn around). And also if bulky and unaesthetic radiators are installed in the apartment, then it is better to dismantle them and equip a warm floor of an electric type;

- universality – such a floor can warm the room, even if other heating appliances do not have enough power;

- comfort – here you can recall the well-known saying that legs should be kept warm. And, true, in this matter, warm electric floors show effective results. If the room is heated by radiators, then the zone of temperature comfortable for a person is located at the top and near the radiator, because it is typical for warm air to rise exactly up. And with heating devices for warm floors, the situation is completely different: the temperature ideal for the human body is located at a height of 100 cm from the floor, and the colder layers are in the upper part of the room. This distinction does not cause any discomfort in people, because it is due to physiology.

The pluses are excellent, but there is also a drawback – it is impossible to reinstall the warm electric floor, you will need to buy the floor, tile and everything else again.

Electric underfloor heating reviews are good, and many consumers are happy with such a miracle of modern technology.

Device, principle of operation

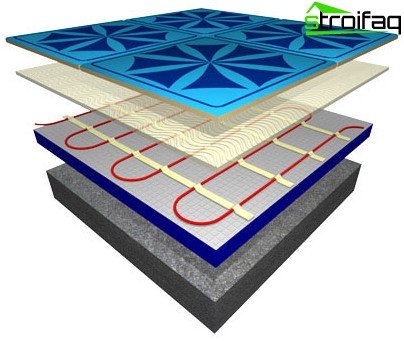

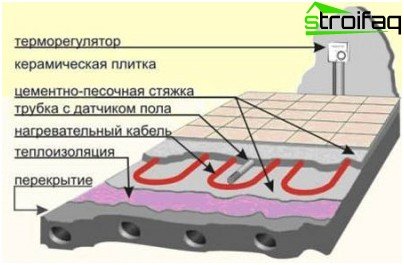

Electric heated floors are arranged quite simply and there is nothing complicated in them. Installation of an electric heat-insulated floor is carried out on a specific heat-insulating material, then cement-sand mortar is poured, the selected floor material is laid on top of the screed obtained. Heat source is electric cable..

The device is a warm electric floor

In case of cable overheating, a short circuit and destruction of the insulating layer is possible. Repairing the electric floor is troublesome because it is very difficult to determine the exact location of the damage. Therefore, you should not save on its purchase, but choose a cable with a high specific heat dissipation, and carefully observe the distance between the threads during installation.

The underfloor heating system consists of a heating section (mat), control equipment (the so-called thermostat with a control sensor), accessories to facilitate installation (corrugated tube, mounting tape) and thermal insulation.

Choice: electric or water?

Many people doubt and wonder which is better: are underfloor heating electric or water? To do this, you need to carry out a comparative description of both species and everything will become clear. The positive qualities of the electric underfloor heating in this article have already been mentioned, now we can recall some more disadvantages:

- small electromagnetic radiation does not have a very positive effect on the environmental atmosphere in the room;

- expensive installation (if it is not done by yourself).

And now let’s name the main disadvantages of the water floor heating:

- there is a chance of damage to the communications when laying the screed. Therefore, the possibility of leakage is not excluded;

- if the pressure in the water supply system drops sharply, then without a pump, the work of a warm floor is impossible;

- it cannot be installed without special permission in city apartments.

And the main advantages include the low cost of water compared to electricity, and installation of water floors is cheaper.

Each person decides for himself which option is closer to him and is guided by his personal criteria..

Types of electric underfloor heating

Which electric floor is better? With a cable system or with a thermomat, or maybe a film floor? By and large, they all differ in the way of installation.

Cable system – a certain length of a heating cable with a given length. It is placed in a cement-concrete screed or in tile adhesive with a zigzag principle or spiral (step 6-12 cm).

Important: this cable must not be cut during installation.

There are two types of heating cable: self-regulating heating and continuous. The first option is used when heating the roof, and the second in “warm floors”.

Self-regulating electric thermomat

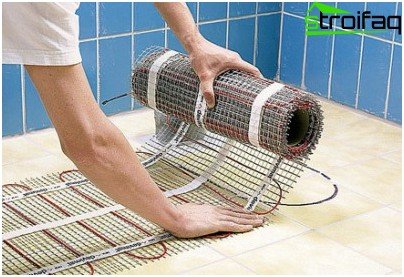

Thermomats – heating cable (thin) on a reinforced mesh. This type of electric underfloor heating is laid on the finished screed in a layer of tile adhesive.

Film underfloor heating – a thin polymer film (0.3-0.5 mm), the heat source is carbon paste, which is sealed in it. Design features make it possible to lay such a film floor directly under the floor covering.

The film electric underfloor heating is distinguished by its simplicity and speed of installation, the insignificant height of the entire “warm floor” system

If we consider all types, we can summarize that the film floor is the most versatile, as it is suitable for tiles, parquet, laminate, linoleum, carpet.

Self-assembly in stages

It’s time to figure out how to connect an electric heated floor with your own hands. Quite often mounted electric underfloor heating in the bathroom.

And rightly so, because this is not only additional coziness and comfort, but also a benefit. For example, drops of water dry on the tile much faster, and this prevents the spread and appearance of fungus.

Laying of electric underfloor heating is carried out evenly throughout the room

The most popular and common type is the heating cable, so the article will consider connecting a warm electric floor of just such a.

Before direct installation, the room is freed from furniture, the old floor is dismantled, and the floor surface is carefully prepared – it is leveled, construction waste is removed, and a thin cement screed is made if necessary..

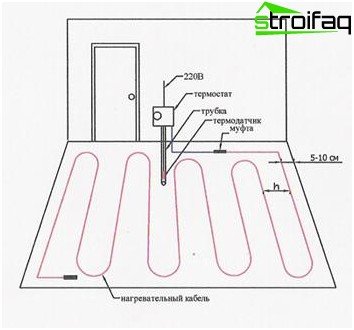

Layout of an electric underfloor heating: the principle of the location of the electric cable, thermostat

Further on the wall, a place is prepared for installing an electric thermostat, it will adjust the floor temperature.

Important: if necessary, to connect the floor you need to equip a separate wiring.

After the preparatory phase, you can begin to insulate and lay the cable. But some masters also recommend the arrangement of waterproofing, in order to avoid the formation of condensation near the heating cable. For this purpose, a plastic film is used..

For thermal insulation, a modern material is often used – penofol, it has a coating of foil (14 microns), as well as of polyethylene foam with a self-adhesive layer. It is a thin and lightweight material that comes in rolls..

Penofol is laid with the foil up, and the joints between the tapes are glued with special mounting glue. When the insulation is laid, then a reinforcing mesh is laid on top of it, which performs such tasks:

- eliminates overheating of the cable in contact with the insulating layer;

- gives strength to the solution, which will subsequently fill the floor.

The cable is mounted with mounting tape fixed to the floor. Such a tape eliminates excesses and thus maintains the necessary distance between the loops. Normal functioning of the electric floor is not possible without the installation of a temperature sensor.

Important: it is necessary to consider the possibility of replacing the temperature sensor in case of breakage, but without destroying the concrete screed.

For this purpose, it is usually installed in a special tube, and it is filled with a screed.

Be sure to check before filling, once again the correct installation and quality of the connections are reviewed. There should not be any mistakes, because it will not be easy to eliminate them; you will have to dismantle the screed. You can check not only by applying voltage, but also with the help of a tester. The parameters of such measurements are indicated in the product passport.

If everything is normal, you can pour a layer of cement screed 3-4 cm thick. In this case, the pouring should be uniform, without voids in order to avoid overheating and failure of the heating system. Well, now it remains only to wait for the screed to completely dry.

It is possible to lay the flooring after 4 days, and a performance check is possible after 30 days. This period is due to thermal expansion, if the heated floor is turned on until it completely dries, then cracks and voids form, and they are very undesirable. You also need to remember that the heating cable does not fit under furniture.

Electric underfloor heating is not a luxury, it is a successful and enjoyable invention that you need to use and enjoy the heat.