Polypropylene pipes and fittings

New construction technologies during the installation of engineering systems instead of the usual pipelines made of cast iron and steel pipes offer much more profitable materials – polymeric. For example, PVC pipes are increasingly used for sewer networks, polyethylene pipes for water supply, polypropylene pipes and fittings for heating systems.

The exact name of the material sounds like a random copolymer polypropylene PPRC, type 3. This is a polymer of propylene (propene). These pipes are also different..

Content

- Varieties of reinforced polypropylene pipes

- Polypropylene pipes for heating: characteristics

- Scope of polypropylene pipes

- What are polypropylene fittings?

- Diameter is a significant indicator

- Installation of heating from polypropylene pipes

Varieties of reinforced polypropylene pipes

First of all, it should be noted that any heating system made of polymer polypropylene pipes is made on the basis of reinforced elements. In this regard, the following types of polypropylene pipes are distinguished:

- polypropylene pipes reinforced with aluminum sheet. Reinforcement can take place in the outer layer, closer to the middle or inner wall of the pipe. The sheet of aluminum is continuous, not continuous, corrugated;

- fiberglass-reinforced polypropylene pipes that are placed in the middle layer by coextrusion. It turns out such a sandwich: the inner layer is polypropylene, the middle one is fiberglass, the outer layer is again polypropylene;

- polypropylene pipes reinforced with composite. In this case, a composite material consisting of polypropylene and fiberglass is used. This is done to improve performance..

Polypropylene pipes for heating: characteristics

Polypropylene pipes are a great alternative to cast iron and steel counterparts. This fact is explained by a number of remarkable properties..

It’s no secret that polypropylene pipes for heating reviews have earned extremely positive. The reason is simple: with numerous advantages:

- the multilayer structure of polypropylene pipes increases wear resistance and allows their use for organizing cold and hot water supply;

- light weight, lightness greatly simplifies transportation to the place of work;

- ease of installation;

- polypropylene pipelines are unpretentious in maintenance, they are tight, they do not need to be painted, unpleasant odors do not accumulate in them, microorganisms do not spread and mineral deposits are not formed;

- polypropylene is environmentally friendly, does not emit harmful substances, does not affect the structure of water;

- pipes made of polypropylene are characterized by a low coefficient of hydraulic resistance, do not vibrate when fluid flows through them;

- pipes do not allow stray currents, are not afraid of the destructive effects of chemicals, mechanical shocks, and withstand high pressure;

- low flammability;

- ability to withstand temperatures up to 120 degrees without loss of quality and deformation of elements (for comparison, in PVC pipes this figure is 60 degrees).

Polypropylene pipes have many advantages.

The advantages of polypropylene pipes can be listed for a long time: low cost, guaranteed service life of more than 50 years, versatility – here are some more pluses in the piggy bank of advantages that explain the unusual demand for polypropylene pipes.

Scope of polypropylene pipes

Polypropylene pipes are characterized by a wide area of application. Remarkable properties and excellent quality indicators allow you to use them:

- in boiler plants;

- in hot and cold water supply systems;

- in central heating;

- for the organization of risers;

- in systems “warm floor”;

- in agriculture, for drainage of sewage and soil water, in drainage, irrigation systems;

- in production, in devices for transporting compressed oxygen and chemical solutions.

What are polypropylene fittings?

Speaking about the polypropylene pipeline, it is impossible not to mention the fittings, which are in charge of connecting all its links and form turns, bends and branches of the trunk. These elements provide the most accurate matching, allowing in practice to implement any heating scheme.

You need to know! For polypropylene pipes, conventional fittings or with a threaded brass insert are used. The former communicate with polypropylene plumbing through diffusion welding, the latter connect both polypropylene and metal pipes.

The market today offers polypropylene fittings, the sizes of which vary over a fairly wide range, which makes it easy to choose the right sample.

Selection of fittings for polypropylene pipelines determine the operating conditions

There are two types of fittings: with and without threaded connections. Threaded fittings, in turn, are detachable and solid. The type of fitting is selected depending on the operating conditions. For example, when connecting a meter or storage tank, a threaded detachable fastener is convenient, and when connecting a hose – one-piece.

Diameter is a significant indicator

The first question that confronts the design of a polypropylene pipeline is the diameter of the pipes..

It is important! The diameter of polypropylene pipes for heating should be selected according to the results of hydrodynamic calculation. The bottom line is to choose the smallest permissible pipe diameter in a particular section. When calculating, the operating pressure and the heating scheme from polypropylene pipes are taken into account.

Diameter – a value indicating where these or other pipes should be installed. So polypropylene pipes of large diameter (200 mm) are used in the construction of structures designed for use by a large number of people (hospitals, saunas, hotels, large shops, entertainment centers). For individual construction, pipes of 20-32 mm in diameter are optimal. They have high bandwidth and easily take the required shape..

It is important! In general, the diameter of the pipe is selected individually, depending on the purpose of a particular heating branch.

For laying pipelines, you can choose a polypropylene pipe with any diameter

Pipes with a diameter of 20 mm are good for a hot water supply system, for risers – 25. The type of heating system also matters, if the heating is central, you can use pipes with a diameter of 25 mm, if autonomous – variations are possible.

When creating a warm floor, you will need polypropylene pipes with a diameter of no more than 16 mm.

Installation of heating from polypropylene pipes

Installation of heating from polypropylene pipes – a process that does not require much effort and takes a minimum of time.

Parts and Tools Requirements

- carry out installation work at a temperature of at least +5 degrees;

- the materials used must not contain damage and pollution;

- polypropylene elements should be protected from open flame;

- threading on polypropylene elements is not allowed;

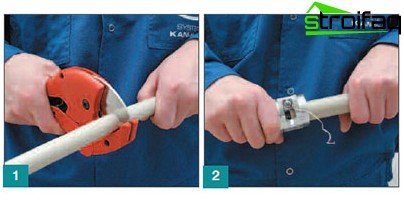

- prepare an electric welding machine for polyfusion welding with nozzles and special scissors for cutting pipes.

Scissors for cutting polypropylene pipes ensure the formation of a smooth cut, facilitate the process of laying the pipeline

You need to know! Scissors can be replaced with a hacksaw or jigsaw. Do not forget to remove chips and burrs after cutting..

Installation of polypropylene pipes: stages of work

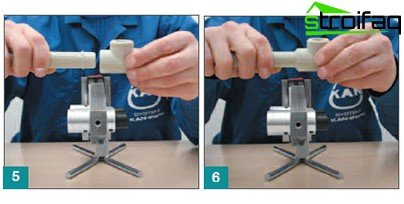

Before installation, the welding machine is heated to a temperature of 2700 degrees, which will create a homogeneous high-quality seam.

1. Measure the pipe to the desired length. When welding a foil pipe, remove the top and middle layer to the depth of the fitting.

2. Deburring the pipe end.

Cut the required length

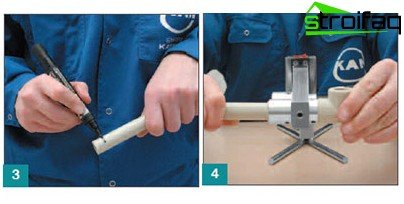

3. Mark the depth of fitting fitting with a marker. To prevent narrowing of the passage, a gap of 1 mm should be left between the protrusion of the fitting and the end.

4. Marking with a marker on the surface of the fitting and pipe, indicating the connection.

5. Nozzle pipe and fitting on the welding machine. Both parts need to be heated at the same time..

Mark the depth of fitting with a marker

6. When the elements warm up, they are interconnected by previously made marks. Do not forget to control the distortions in the axial and radial directions. The seam solidifies within 10-30 seconds. This allows a small correction if necessary..

We heat the elements and connect them

7. The remaining components of the pipe are connected in a similar way. It is recommended to determine the connection order in advance, so the work will go much faster.

Now that you know how to install polypropylene pipes, you don’t have to worry about the quality of the heating, because it will be just perfect. Polypropylene pipes for the heating system – the key to comfort and warm atmosphere in your home.