Floor heating gas boilers

Any residential building, if it is intended for year-round use, must be heated. Currently, the market for heating appliances offers the consumer a huge number of a wide variety of products. They are classified according to many signs: depending on the material of manufacture, dimensions, fuel used, principle of operation, etc. One of the most popular appliances for heating an apartment building is gas floor boilers, presented by manufacturers in a fairly wide range.

Content

- The principle of operation of gas boilers

- The heat exchanger is the main element

- Types of floor gas boilers

- Single circuit unit

- Double-circuit floor gas boiler

The principle of operation of gas boilers

It is worth noting that the principle of operation of the floor gas boiler extremely simple. For its operation, natural or liquefied gas is used, which, when burned, gives off its heat to the heat exchanger in the device. That, in turn, heats the water passing through it, pumped by a special pump. After that, the same circulation pump delivers the already heated water to the heating circuit..

The heat exchanger is the main element

For the efficient operation of a gas boiler, a high-quality heat exchanger is needed, for the manufacture of which a wide variety of materials are used: cast iron, steel, copper. This or that material determines not only the efficiency of the device, but also its durability.

So, floor gas heating boilers, the heat exchanger of which is made of cast iron, are the most durable. The fact is that the cast-iron heat exchanger is not subject to corrosion and extremely rarely burns out. Such a device can be operated for about 50 years, but it is worth considering that cast iron is a fairly fragile material. Strong shock or contrasting water temperature may cause cracking..

Cast iron floor gas boiler heat exchanger

Steel heat exchangers are more resistant to cracking and various kinds of deformations. In addition, their weight is less than that of cast-iron counterparts by about 2 times. With such advantages, steel heat exchangers lose in the fact that they corrode quite easily and quickly burn out. The life of such a gas boiler depends on the type of steel used and ranges from 5-15 years.

Copper is practically not used for the manufacture of heat exchangers. Such products are less and less common in the market for heating appliances..

Types of floor gas boilers

Today, owners of country houses have the opportunity to choose between single-circuit and double-circuit gas boilers, which have a number of fundamental differences.

Single circuit unit

The main purpose of a single-circuit gas boiler is to heat a living room. The design of such a device does not provide for the presence of functional elements that make it possible to provide a residential building with hot water. This leads to the fact that for the device of hot water supply it is necessary to purchase additional equipment. The result is a holistic system, each element that clearly and effectively performs its function.

Single-circuit floor gas boiler

To date, there are several options for building such a system:

- Economical. In this case, a flow-through gas water heater becomes an addition to the floor single-circuit gas boiler. Such a system is sufficient for the full service of two points of drawoff. In addition, it provides minimal fuel consumption..

- Optimal. This option involves the removal of a heat exchanger from the gas boiler, which is placed in an indirect heating boiler. Such a system allows for a sufficiently large daily flow rate.

However, when installing the system with a boiler, it is necessary to coordinate the power of two devices. The fact is that with a boiler power less than that of a boiler, it will be quite difficult to provide a living room with the necessary daily amount of hot water. Boilers, the volume of which is 250 or 500 liters, will completely satisfy the needs of a small family with sufficient boiler power. In some cases, additional electric heating is allowed, accelerating the heating of water to the desired temperature.

Floor-mounted gas boiler and water boiler

When choosing a single-circuit gas boiler, you should pay attention to a number of its characteristics:

- power;

- voltage;

- dimensions;

- type of combustion chamber.

Thus, a single-circuit floor gas boiler is a heating device in which, when gas is burned, water is heated and distributed through pipes.

Double-circuit floor gas boiler

The gas double-circuit floor boilers available in the assortment can be used both for the installation of an autonomous heating system in a suburban residential building and for ensuring hot water supply.

Such a boiler is the most optimal solution in the case when the amount of free space does not allow to install a system consisting of a single-circuit gas boiler and a boiler.

Any gas double-circuit gas boiler includes the following functional elements that ensure its efficient operation:

- circulation pump;

- burner;

- expansion tank;

- heat exchanger.

To ensure heating and hot water supply, it is only necessary to lay pipes to mixers and radiators.

Double-circuit floor gas boiler

The functioning of the double-circuit gas floor boiler takes place in accordance with the priority mode of hot water supply. In a simplified form, it looks as follows: the consumer opens the water tap, after which the heating circuit is switched off. In this case, the burner works only on the water supply circuit. Water heating is carried out in flow mode.

It is worth paying attention to one nuance. With a rather large daily water consumption, for example, when a family has more than three people or has several bathrooms and bathrooms, experts recommend choosing double-circuit gas boilers with a built-in boiler. This will avoid a rather long shutdown of the heating circuit. If these measures are not taken, there is a risk of actively using hot water, but in a poorly heated apartment building. It is unlikely that this prospect can be considered joyful in the harsh Russian winter.

Installation of floor gas boilers

Today, a floor gas boiler is one of the most economical heating devices, since gas is an affordable and relatively cheap type of fuel. If there is a centralized gas supply, the installation of the boiler will not take much time. It will be enough to just connect to it and from now on do not worry about the temperature of the batteries.

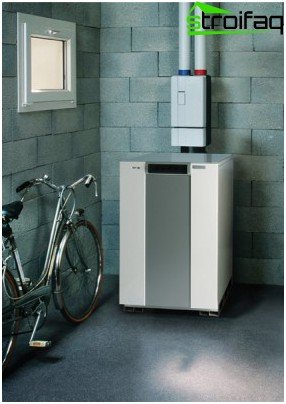

It is worth noting that floor boilers are quite heavy and differ in large dimensions, so it is recommended to install them in a boiler room specially designed for this purpose. In addition, the boiler must be equipped with a high-quality chimney, which will remove gas products of combustion.

Installation of a gas boiler in a boiler room

A number of requirements are set for the decoration of the boiler room and its equipment, established by the relevant state body. So, they relate directly to the boiler room, communications in it, ventilation and the installation of the chimney.

For example, the materials used to decorate the boiler room must be fireproof and non-combustible, and the free area for installing one boiler should be at least 4 sq.m. In the boiler room there should be a sewage system, electricity and water supply. The gas boiler itself is installed on a flat floor surface and away from sources of fire. Approach to the boiler must be unobstructed from any direction..

Security features

A modern floor gas boiler is a heating device that fully meets all safety requirements. Safe operation is ensured by competent arrangement of the boiler room and compliance with the rules for using the device.

It is worth noting that manufacturers have tried to foresee the moment of operation of the boiler when the power is turned off. This is especially important for the reason that the vast majority of boiler models are electrically dependent. So, at the moment of power outage, the gas supply is blocked and, as a result, the burner goes out. Of course, the boiler completely stops its work.

When renewing power supply, those boiler models that are equipped with a self-starting function resume operation automatically. If not, a mechanical start is required..

In addition, each floor gas boiler is equipped with a variety of sensors designed to respond to the slightest malfunctions and malfunctions. Such failures occur, however, extremely rarely, since boilers can successfully function in almost any environment, around the clock in non-stop mode. This will provide much-needed confidence and peace of mind..

Thus, the variety of modern gas-fired boilers of the floor type allows you to choose the model that is most suitable for operation in the existing conditions and will be available. A properly selected product of the required power and degree of functionality contributes to the effective heating of a residential building, the design of a hot water system. It is obvious that in that house, where it is always warm, a pleasant atmosphere of coziness, comfort and hospitality will be created.