Boilers for heating a private house

Construction of a country house is a laborious process consisting of many stages. Indeed, in order to create your own cozy nest, you need to do a tremendous job, starting with the design of future housing and ending with the selection of furniture and curtains. Among these troubles, the installation of the heating system is one of the priority places. Heat in the house is an important component of a comfortable environment, and heating boilers for a private house are a reliable means for creating it..

Content

- Guidelines for selecting a boiler for a private house

- Gas heating equipment

- Specific differences of electrical units

- Solid fuel boilers

- Liquid fuel boilers

- Combined heating systems

Guidelines for selecting a boiler for a private house

The modern market offers a huge range of heating boilers from foreign and domestic manufacturers. The availability of a particular type of fuel is a determining factor when choosing. Consider the main types of boilers for a country house.

Gas heating equipment

This type of boiler for heating is the most common. The popularity is due to the availability and relative cheapness of fuel – factors that make the application gas boilers the best method of arranging an autonomous heating system. Depending on the burner, gas boilers for a private house are divided into atmospheric and supercharged. In the first case, the exhaust gas removal process is carried out due to the chimney draft. In the second, processed products are removed through a special pipe using a fan. Boilers with a fan do not require a chimney, but they also cost, of course, much more expensive than counterparts equipped with an atmospheric burner.

Gas boiler – a rational option that processes the cheapest type of fuel

When choosing, it should be noted that gas boilers for a country house are divided into floor and wall. Do you want to get hot water in addition to heat? Choose a wall-mounted boiler, otherwise you will have to install a boiler for hot water. The wall-mounted gas boiler for a private house is economical, because All necessary equipment is included in the package (pump, pressure gauge, thermometer, expansion tank etc.)

It is important! The advantage of wall-mounted gas boilers is also the possibility of taking combustion products directly to the street (when choosing a model with the forced removal of waste substances).

It should be noted that the operation of a wall-mounted boiler is possible only with uninterrupted power supply. If this is not observed, then the house will have neither hot water nor heat. Power surges Is a regular occurrence in your home? Then it is better to pay attention to floor-standing boilers, the functioning of which is completely independent of electricity. But here it is important to take into account a small nuance: worry in advance about a good chimney, because a floor boiler for heating a country house will only work effectively if there is draft.

The market includes steel and cast iron boilers for a country house. Which one to choose – decide for yourself. A combustion chamber (heat exchanger) is made of cast iron or steel. The cast-iron heat exchanger is heavy but fragile, which requires care in transport. Otherwise, cracks may appear on the case, which will adversely affect the life of the equipment..

Steel heat exchangers are durable, weigh a little, but they are subject to corrosion, therefore, when purchasing a steel boiler, you need to control the temperature: it should not fall below the dew point, because this may cause rust on the walls of the chamber.

Specific differences of electrical units

In the absence of a gas main pipe, it is necessary to look for alternatives for autonomous heating. An electric boiler may well become such an option. It is compact, easy to install and operate, more environmentally friendly (does not produce harmful waste during operation).

It is important! The widespread use of electric boilers is hindered by two factors. For heating 150 sq.m of the premises, 15 kW of power is needed, which is technically not always possible. And secondly, it’s quite an expensive pleasure.

The electric boiler does not require the installation of chimneys, is easy to operate, but not economical due to the high cost of energy, therefore it is most often used as additional equipment

Electric boilers are often used as a backup option in tandem with solid fuel systems, which is done solely for reasons of economy. In this case, the solid fuel boiler carries the main load, while the electric one maintains the specified temperature.

Solid fuel boilers

Perhaps this type of boilers can be called the oldest, used in an autonomous heating system for many years. Their main advantage is the availability of fuel, which can be used firewood, peat briquettes, coal, coke. Among the shortcomings, it is worth noting the inability to work completely offline.

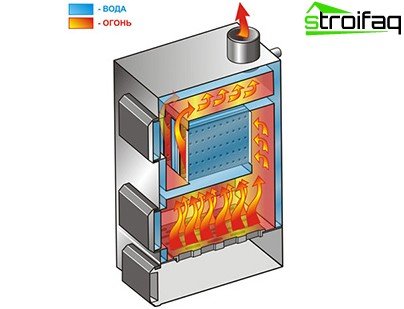

Design and principle of operation of a solid fuel reprocessing boiler

Improving the technology of solid fuel systems has contributed to the emergence of new boilers – gas generating. In these boilers, pyrolysis is used – a procedure in which under the influence of high temperatures gas is released from the wood, which is the main source of fuel. Such heating systems of a private house have an efficiency of 2 times more. Of the minuses, you can see a high price, because pyrolysis is impossible without a sealed chamber, which is expensive to manufacture.

Liquid fuel boilers

Liquid fuel boilers use diesel fuel. If you decide to install a boiler of this type, then there is no need for firewood, but there is a need for a tank with diesel fuel.

The main disadvantage is the cost of the burner, comparable to the cost of gas boilers with atmospheric burners. But such a device has several power levels, which helps to consume fuel economically.

Liquid fuel boiler: most models can process not only diesel or kerosene, but also gas into thermal energy

You need to know! There are samples with replaceable burners for the transition from diesel fuel to gas or with components operating simultaneously on gas and diesel fuel.

Combined heating systems

This type of boiler equipment allows the use of any fuel, from gas to electricity.

Installation of a gas boiler in a private house

Installation or replacement of the boiler in a private house (especially if the boiler is a gas boiler) is allowed only after the preparation of the relevant documentation. Permission can be obtained if a list of conditions is met.

Technology Requirements

- the room should be at least 4 m2 with a ceiling height of 2.5 meters at least. The width of the doorway is 80 cm;

- ventilation is mandatory, as well as providing natural lighting for the boiler installation through the window;

- it is necessary to install a chimney with a cross section corresponding to the boiler power (with a power of 30 kW, the diameter should be 13 mm, and with a power of 40 kW it should already be 170);

- power supply must occur at the expense of a special machine, in which current and thermal protection are configured;

- in the room where the boiler is located, a gas analyzer and an electric valve should be installed, which serves to stop the gas supply;

- installation of gas equipment in basements is not allowed;

- the gas pipeline should be made of metal pipes. It can be either open or closed;

- It is forbidden to lay a gas pipeline in fire hazardous areas;

- the boiler must be equipped with a sensor.

It is important! Installation of gas boiler equipment without the intervention of special organizations that not only carry out installation, but also draw up all the necessary documentation is not recommended.

Stages of replacing gas boiler equipment

Only a professional can install a gas boiler for a private house, because the slightest mistake can lead to an explosion. In general terms, the process looks like this:

Installation of heating equipment

1. Flushing the old system. The successful operation of the new boiler depends largely on the condition of the piping system. The operation is carried out using a compressor that removes contaminants under high pressure.

2. Dismantling of old equipment.

3. Installing a new boiler. During installation, the manufacturer’s recommendations specified in the instructions must be taken into account.

4. Connecting the boiler to the chimney system. This provides the output of combustion products and provides oxygen for combustion if the chamber is of a closed type. It is important to comply with the requirements for the height of the chimney, as if it is insufficient, the combustion waste will inevitably fall into the room.

5. Connecting the boiler to the gas pipeline. The procedure is allowed for organizations that have an officially certified supporting document.

6. Insert the boiler into the PVA system and the heating system.

7. Commissioning is the most important stage on which the efficiency of the installed equipment depends.

Installation and connection of a new gas boiler

As already mentioned, the installation of boiler equipment is a job for specialists, but a minimum of theoretical knowledge will not hurt. Installation of a gas boiler is carried out in the following sequence:

- checking the complete set of the boiler (pipelines, mounting template, strip for connecting gas and water, boiler);

- level selection for fastening the hinged bracket and the bracket for connecting to the mounting template;

- attaching a strap;

- installation of gaskets on pipelines of water and gas;

- removal of protective caps;

- installation of the boiler using slats;

- connecting the water circuit and gas supply to the equipment;

- power connection;

- communication of the boiler with a coaxial pipe or chimney;

- connection of drain valves.

The process of installing a gas boiler is completed – you can enjoy comfortable conditions and a carefree pastime in the lap of nature, without experiencing discomfort. After all, your country house will now be very warm and comfortable.