Expansion tank for water supply

In the cold season, when the window is cold and damp, when you want comfort and warmth, it is especially important to have a good heating and water supply system. And in order to avoid interruptions in their work, it is worth paying attention to such an important element as an expansion tank for water supply in advance. It is precisely on its technical condition that the reliability and durability of these life-supporting systems depend.

Content

- Types of expansion tanks for water supply and heating

- Features of the selection of the expansion tank

- What is the principle of work?

- Key installation accents

Types of expansion tanks for water supply and heating

Expansion tanks are integral attributes of boosting water supply systems, heating systems, as well as fire extinguishing systems. There are two main types of them:

- Open expansion tank. It is a tank at the bottom of which there is a connection to the heating pipe. It is characterized by the dependence of the water level in it on the total volume of fluid in the system. The higher the temperature of the water, the greater the indicator of its volume. The tank is located at the highest point of the heating system, usually in the attic of a building. To reduce heat loss through its walls, the tank is insulated. The open expansion tank is leaky, unaesthetic, bulky, therefore not suitable for indoor use.

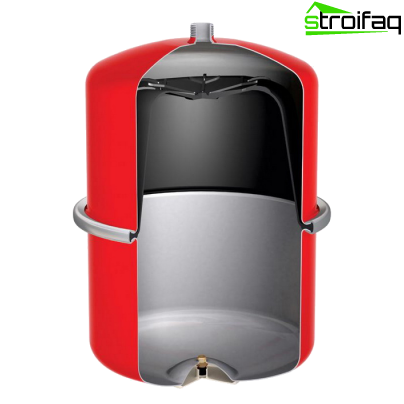

- Closed expansion tank or membrane expansion tank. It is a sealed metal container-capsule having an oval or spherical shape. Inside, it is separated by a membrane made of heat-resistant rubber. As a result of this, two chambers are formed – liquid and air. A valve is installed inside the air compartment for bleeding (lowering) the air at the time of a strong increase in pressure. Thus, the liquid occupies the internal volume of the tank.

Features of the selection of the expansion tank

In order to make the right selection of the expansion tank, it is necessary to know exactly the total volume of the coolant.

In addition, his choice should be based on strict compliance with the maximum permissible limits of the pressure range in the heating system.

Membrane Type Expansion Tank Design

You need to know that the overestimation of the declared volume of the expansion tank on its operational parameters, as well as on the functioning of the heating system as a whole, is absolutely not affected. And finally, when choosing, it is worthwhile to calculate the expansion tank, taking into account the fact that the coolant is allocated a limited volume inside the tank. And the indicated initial excess and maximum permissible pressure values, taking into account the respective coefficients for each of them, determine the largest part of the total volume of the expansion tank allocated for the coolant.

It’s important to know! The operation of the tank, which is characterized by a low volume of water, will invariably entail negative consequences. Obviously, its use at the time of maximum thermal loads, that is, when the pressure in the system approaches the maximum permissible values, will lead to the flow of coolant in the places of the threaded connections of the tank or to the formation of cracks. An expansion tank for heating, used when the system operates at low heat loads, will cause a decrease in pressure in the system, and as a result of a decrease in the volume of coolant. As a result, atmospheric air seeps into the tank.

Typically, membrane type tanks are manufactured with a fixed membrane, which is rigidly attached to the tank section. The outer surface of the tank is covered with red enamel, and the inner cavity that is directly in contact with the working medium, that is, the coolant is a special moisture-resistant paint.

Worth paying attention to! Unfortunately, there is no universal material for the manufacture of membranes. But still, in the process of choosing a tank, you should pay attention to the type and quality of the membrane.

Any membrane has the following performance characteristics:

- Operating temperature range;

- sanitary and hygienic requirements;

- durability;

- dynamism of the system;

- resistance to water diffusion.

What is the principle of work?

If we analyze the principle of operation of an expansion tank belonging to the membrane type, then it consists in the following: a heat carrier heated in a closed circuit expands when the volume increase reaches the tank capacity, the membrane stretches, thereby reducing the proportion of air space similar to a piston (i.e., air is compressed). During this period, the pressure in the tank of the expansion tank, and accordingly in the whole system increases. When the temperature of the water decreases, its volume in the heating system decreases. In addition, the pressure decreases, so the previously received water is pushed back into the system by means of compressed air.

It’s important to know! Before you install an expansion tank in your own home, even at the stage of selection, you must make sure that you have a quality certificate, and in some cases a safety certificate. It is in this case that you can be sure that the selected element of the heating system will be reliable and functional..

If there is a slight leakage of liquid, then the pressure in the system and in the expansion tank drops, and the compressed air squeezes out the reserve volume of water, thus charging the heating system. The initial stage of operation of the heating system involves circumstances in which the pressure of the coolant will be to a certain extent greater than the hydrostatic pressure of the system. For this reason, the liquid chamber of the expansion tank receives the coolant in an amount that corresponds to operational losses. With an increase in the volume of the liquid chamber of the tank, the volume decreases and the pressure in the air chamber of the tank increases. Thus, the steady-state pressure is the initial operating pressure of the heating system..

Now, without problems, you can pick up an expansion tank with the required volume

Key installation accents

Of course, the installation of an expansion tank requires a professionally prepared project, as well as installation instructions.

Initially, the tank is supplied with gas that fills the entire internal volume and is under overpressure. Immediately prior to installation, the tank is charged to a pressure whose value has been previously calculated.

The installation of an expansion tank is accompanied by the following features:

- A container with a volume exceeding 500 l may not go into a standard doorway.

- Installation of check valves and filters on the branch connecting the expansion tank and the heating system is unacceptable.

- The expansion tank must be connected taking into account further maintenance. And this requires the installation of valves on the branch to the tank, and in such a way as to exclude accidental closure.

- Pipeline section: the shut-off valve-nozzle of the tank must be equipped with a drainage valve.

- In the immediate vicinity of the installation site, the connection scheme for the expansion tank must include the installation of a pressure gauge and safety valve.

Expansion tanks for heating systems usually involve thermal power of up to 6 MW. If it implies the operation of heating systems of greater power, then due to constant water leaks, it is necessary to ensure round-the-clock uninterrupted operation of the make-up pumps.