Cast-iron radiators (batteries)

Heating radiators Pig-iron can already be safely called a classic of the heating infrastructure of a number of countries, including Russia and other CIS members, although abroad they have long been obsolete equipment and are practically not used. At our peak of popularity, the beneficial properties of cast iron keep them. This is a good resistance to corrosion, which affects the length of the period of use without repair; and immunity to the destructive effects of various impurities added to the coolant; and ease of operation. And in general, the majority of Russian heating systems do not allow the use of other types of batteries. Let’s consider in more detail what is cast-iron radiators.

Content

- Design features, principle of operation

- Advantages of cast iron radiators

- Cast Iron Battery Disadvantages

- Can a cast iron radiator be beautiful?

Design features, principle of operation

Cast iron heating batteries are poured out of a cast iron alloy characterized by a uniform mass, and are intended for operation in centralized and autonomous heating systems. Sections are made separately, and then connected to each other to the desired length using special gaskets designed to ensure complete tightness, and cast-iron nipples.

The specifications for cast iron radiators depend on the model of equipment. We will not consider each type separately, we restrict ourselves to general properties.

- The inner ribs of cast-iron batteries are arranged vertically, which provides better heat transfer.

- The temperature of the coolant for cast-iron radiators should not exceed 150 ° C.

- The optimum crimping pressure is 18 bar.

- Cast iron battery operating pressure 9-12 bar.

- The power of cast-iron heating radiators ranges from 100-150 watts, depending on the model.

- High inertia, i.e. slow heating and the same slow cooling, which makes it pointless to adjust the heating.

Interesting: the power declared in the technical specifications is always different from the actual one. The explanation is very simple: equipment testing takes place in laboratory conditions, close to ideal. In real life, when the temperature of the coolant in the boiler is 60 ° C, the power will not rise above 50 watts. That is, if you want your radiators to be heated to 60 ° C, you must maintain the temperature of the boiler at 75 ° C.

Modern cast iron radiators

The principle of operation of cast-iron radiators is absolutely no different from all others. The coolant heated to the required temperature enters the radiator compartments through pipes and heats the air in the room by means of heat transfer.

The following types of cast iron batteries are presented on the modern construction market:

- Single channel;

- Two-channel;

- Three-channel.

Advantages of cast iron radiators

Despite its “rich life experience”, cast-iron batteries (and they are already over a hundred years old) continue to be actively used.

Let’s try to find out the reasons for their popularity among consumers. So, the advantages of cast-iron radiators:

- Increased inertia. Let’s start with this highly controversial point. For residents of foreign countries, the inertia of heating equipment is more a disadvantage than a virtue. After all, the temperature of the inertial system is almost impossible to regulate. In our harsh winter conditions, this minus turns into a fat plus, because even if the circulation of hot water ceases (this is especially important in non-automated solid fuel systems), cast iron will transfer heat energy to the room for a long time, preventing the housing from cooling down quickly.

- Admixtures in coolants. In centralized heating systems, water is heated at the TPP, where various additives and dyes are added to it. This is done so that when breaking through underground utilities by the color of the protruding water, you can quickly understand which system has suffered: water supply or heat pipe. In addition, when moving through pipes, the coolant is saturated with many other chemicals that, getting into radiators, cause corrosion of internal surfaces in the shortest possible time. Cast iron heating radiators customer reviews describe how the equipment is highly resistant to damage and corrosion.

- Long service life. Cast iron batteries can last more than 50 years under the condition of regular maintenance, including replacing gaskets between sections, and flushing the radiator cavity.

- Low hydraulic resistance. Due to this indicator, cast-iron radiators can be used in non-automated solid fuel systems, that is, systems with gravitational coolant circulation.

- The wide cross-section of the channels ensures normal functioning even with some scale deposits in the system.

Various models of cast iron radiators

Cast Iron Battery Disadvantages

But do not think that this is an ideal device for heating. Like all other types of batteries, they have a number of significant drawbacks:

- Cast iron heating radiators are very bulky sizes, which greatly complicates the installation of equipment. In addition, they are very heavy, some batteries reach 100 kg.

- Complex intersection space does not allow to completely clean the device from dust accumulating in it.

- Low efficiency of heat transfer control of the carrier, which is due not only to the heat capacity of cast iron, but also to the large capacity of the sections.

- Slow warming up of the room. On average, the heat transfer of one section is 110 watts, and the heat transfer of aluminum or bimetal radiators is almost one and a half times greater. This is true, but until we consider the difference in heating methods. In aluminum – convection-air, in cast iron – the radiation method of transferring thermal energy. So it is the radiation method, in which not only the air is heated, but also nearby objects, is considered the most effective.

- Unpresentable appearance. Sullenly standing under the window, a shabby cast-iron radiator is able to nullify all the efforts of the owners of the apartment to improve their own housing. Such a colossus is very difficult to completely mask with screens or grilles, so many switch to aluminum or bimetal analogs, which are distinguished by their elegant design.

Cast iron heating radiators are massive, which complicates installation

Tip: the replacement of radiators must be coordinated with special organizations responsible for the proper operation of utility networks.

Can a cast iron radiator be beautiful?

The last shortcoming of cast iron batteries that we identified was their unpresentable appearance..

So do they always remain so ordinary and boring, or is there still the opportunity to choose a cast-iron device to suit the individual tastes of the owner? In the manufacture of cast-iron radiators in the first place is their low cost, so all models manufactured for the mass consumer are unpretentious.

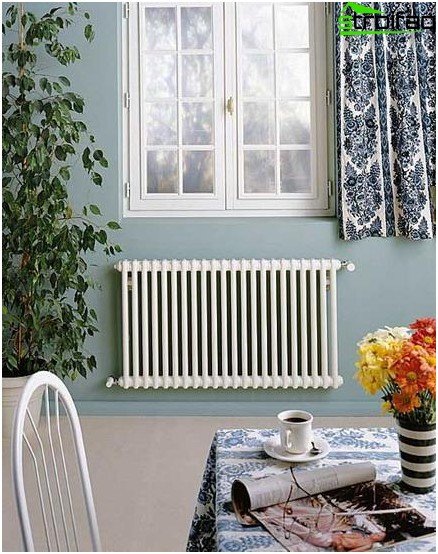

Cast iron radiator in the interior

Not everyone knows about such a type of production as art cast iron, with the help of which an original ornament can appear on the surface of a heating device, suitable for the general style of the room. True, such a radiator is expensive, one six-cell battery will cost more than $ 250.

But then such beauty will not only not have to be hidden, but even vice versa, you will want to flaunt it. Perhaps someday manufacturers will so master this technology that cast-iron radiators again outshine all their competitors.

So, acquiring cast-iron heating radiators, do not rush much. It is better to sit down and think about whether it is worth installing them in your premises, or it is better to immediately use other, more modern batteries.