Installation of underfloor heating in the bathroom

Warm floor in the bathroom – comfort accessible to everyone. What could be better than the feeling of warmth that you experience when walking barefoot in the bathroom? In addition to pleasant tactile sensations, the heated floor in the bathroom successfully eliminates excessive moisture, preventing the occurrence of fungus and mold. Installation of a system of underfloor heating can be carried out throughout the living area, but the most popular is the installation of such floors in the bathroom.

There are two different systems of underfloor heating – water and electric. The basis of each of them is the use of certain heat sources. A step-by-step instruction that describes the installation process of each of the systems will help you to make a warm floor in the bathroom yourself, without the help of qualified specialists.

Content

- Water “warm floor” in the bathroom

- Installation of floor heating

- Underfloor heating water system

- Floor device with heating cable

- Installation of floors based on thermomats

Water “warm floor” in the bathroom

Let us dwell on some of the distinguishing features of a water floor heating. It should be noted that the installation of a warm floor in the bathroom is acceptable for a private or country house. For residents of apartments in high-rise buildings, it is quite problematic to connect such a system to central heating. Of course, this does not apply to “elite housing”, the project of which often provides for the installation of a water heated floor.

System of water underfloor heating in the bathroom

There are plenty of positive aspects of such a warm floor system to solve the issue of its installation. Indisputable advantages include:

- Safety – the elements of the warm floor are reliably hidden from free access, which reduces the likelihood of damage. Due to the small number of joints, minimizing the risk of leaks is achieved;

- Profitability – a water heated floor allows you to reduce energy costs by 15-45% while maintaining a comfortable temperature in the room;

- Environmental friendliness – the system is safe for human health. Water floors do not emit harmful radiation and do not create an electromagnetic field;

- Comfort – the quality of a warm floor, allowing you to experience pleasure when leaving the bath or shower. Adjusting the temperature allows you to provide an optimally comfortable surface temperature..

The disadvantages present in the water heated floor include:

- The existence of a leak probability, which will be very difficult to find when it occurs;

- Mandatory Availability water pump to maintain pressure when it falls in the water supply system;

- The complexity of installing a warm floor system.

It should be noted that a water heated floor is positioned as a complex engineering system that requires taking into account the parameters of your home when drawing up a project.

The choice of equipment for installation depends, first of all, on the existing features of energy supply.

Installation of floor heating

Underfloor heating water system

Let us consider in more detail the features of installing a water heated floor, stopping at each stage.

The modern water heated floor in the bathroom is a construction of pipes that connect to a source of hot water. The latter is a hot water pipe or a heating pipe. Through the circulation of water through pipes included in the floor structure, its upper layer is heated. Then heat, rising up from the heated surface, helps maintain a comfortable temperature at a low level.

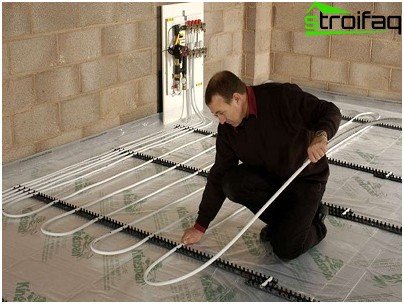

Installation of water floor heating

The installation process begins with the installation of polypropylene risers for hot water, provided that they have not been previously installed. A prerequisite is to draw up a diagram (project) of the location of these pipes.

One of the things that determine the quality of work is competent floor waterproofing, which avoids serious consequences in case of leakage. Strips of waterproofing material must be overlapped, and the seams should be connected using a blowtorch, a hair dryer. Good waterproofing is the result of high-quality joints.

The rough screed is poured with a mixture of expanded clay with cement. It should be noted that the level of this screed must be kept at a mark defined as the level of the finished floor minus 5-7 cm. When pouring the surface, small and small irregularities are allowed. Within 2-3 days after the work, it is necessary to moisten the surface of the screed with water in order to avoid cracking.

The next step is the laying of foil insulation. Joints of strips are glued with aluminum tape.

Laying polypropylene pipes

Next, we proceed to the direct installation of the water floor system. We bend the polypropylene pipe according to the scheme and attach it to the screed. It is important that the distance between adjacent parts of the pipe does not exceed 15-20 cm. The curved structure, which turned out as a result, must be connected to the risers using a control valve. To avoid trouble, immediately check the system for leaks. If there are no problems, turn off the water supply and allow the floor to cool..

The second screed is poured with a similar mixture. Before this, we establish beacons to withstand the level. At this stage, surface evenness is an important point that you should pay attention to. After the screed has dried, you can start laying the tiles.

Floor device with heating cable

Installation of an electric warm cable floor system consists of several important steps that require successive execution.

Design. On the surface of the floor in the bathroom, you need to determine the location of the cable, sensor and thermostat connection points. Next, we transfer the resulting scheme to the plan. When drawing up a project, we build on the power of the system, observing the recommended step between the bands of material.

Thermal insulation. The insulation layer is laid on the surface, the irregularities of which can be 7-8 mm. If during the inspection of the base there are significant differences, then a preliminary concrete screed is required. If the insulation does not have a reflective film, it is necessary to lay aluminum foil in addition.

Cabling. It is better to lay the heating cable on the metal grid on which it is fixed. In addition to the locking function, such a special mesh will not allow the wire to be immersed in the screed and will provide rigidity to the entire structure. We carefully monitor that there is no crossing of the cable or its damage. The electric cable is connected to the thermal cable using a sleeve, which must be immersed in a cement screed and located as short as possible from the thermostat. Keep a distance of at least 20 centimeters between the nearest wall and the junction.

Installation of electric floor heating based on a heating cable

Installation of a thermal control system. The regulator is installed at a height of 0.8-1 m from the floor. The sensor is placed in a corrugated tube and placed between the rows of cable. Carrying out the further filling of the cement screed, we control that the tube and the sensor are higher than the screed itself.

Flooring the floor. The work is nearing completion, so once again we carefully check the integrity and absence of damage to all elements of the electric cable underfloor heating system. After making sure that everything is in order, we proceed to fill. Cement mortar should be evenly distributed, and there should be no voids in the screed. Next, check the integrity of the entire system and let it dry. The first inclusion of an electric underfloor heating should be done no earlier than 30 days after completion of work, which will help to avoid cracks in the screed.

Pouring screed

Installation of floors based on thermomats

The process of installing electric underfloor heating using thermomats is not much different from installing a system using a heating cable. But the difference is still there.

Layers of flooring are laid in the following sequence:

- Draft floor (concrete);

- Thermomats

- Tile adhesive

- Tile.

At the first stage, thermomats are laid on the prepared subfloor, pre-treated with a primer. Even old floor tiles can serve as a base. In places where stationary objects will be located, thermomats do not fit.

The reinforcing mesh of the heating mat is carefully cut, avoiding damage to the cable, and then the thermomat is laid in the right place. Between adjacent strips we observe a distance of 5 cm.

Installation of electric underfloor heating based on thermomats

The thermomat is fixed to the floor with adhesive tape and a thermogun. In addition, mats having an adhesive base are commercially available. Such a system does not require additional fixation. Thermomats are first rolled to the surface and cut, and then the protective strip is removed and glued.

The final stage of work is connecting the sensor and thermostat, isolating the connection points and checking the functionality of the system.

Underfloor heating is easier to install and cheaper than its counterpart based on heating cable. Such a system is available for laying under any floor covering..

Electric floor in the bathroom

The system of electric underfloor heating is more popular. The constituent elements of its design are:

- Heating cable, the purpose of which is the conversion of electrical energy into heat;

- A temperature controller equipped with a sensor plays an important role in the operation of an electric underfloor heating. It is necessary to control the heating system;

- Corrugated tube;

- Thermal insulation material;

- Mounting tape.

There are two types of electric underfloor heating in the bathroom:

- Warm cable floor – a heating wire acts as a heating element, which can be single-core and two-core. Each of these types of cable is laid under a screed having a thickness of 3-7 cm;

- Warm floor from thermomats – is a system of individual parts of heating wires of different lengths. Power supply is due to the presence of “mounting” ends. Thermomats are laid directly on the screed, and then a layer of tile glue is applied. The use of heating mats does not have any effect on the height of the floor, as they are immersed in tile adhesive.

Electric underfloor heating in the bathroom

An electric heated floor, arranged in the bathroom, will give you a comfortable temperature, regardless of the time of year or the operation of central heating. Special regulators allow you to set an acceptable temperature and change it as necessary. Most often, the bathroom area is not large, and after installation of the equipment it is still reduced (for example, under the sink or shower cubicle, a floor heating device is not required). Therefore, the installation of an electric underfloor heating also becomes cost-effective.

In conclusion, I would like to note that the warm floor in the bathroom is your comfort and coziness. Modern technologies allow you to choose the most suitable system according to technical characteristics and price category. Give yourself joy and a feeling of warmth about your bare feet. Let your dream come true!