Solid fuel boilers long burning

Solid fuel boilers for long burning are special devices that allow you to organize autonomous heating of a house or apartment. The first designs of these devices have been known since time immemorial, when people heated the house only with their help for lack of natural gas and electricity. Now most houses are gasified and electrified, but in the most remote areas where no such communications are laid, a solid fuel heating boiler is indispensable.

Content

- Solid fuel boiler experts

- Types and principles of work

- Solid fuel boiler installation

Solid fuel boiler experts

Specialists in the field of heat supply distinguish a number of indisputable advantages of solid fuel boilers:

1. Low cost.

2. The ability of combined and universal boilers to operate on different types of fuel.

3. Inexpensive fuel (firewood is 15 times cheaper than electricity, diesel fuel is 7 times cheaper, and coal is about 2 times cheaper).

4. Autonomy: there is no need to connect them to the electric network and other communications.

5. High efficiency and automatic water temperature maintenance function.

6. The presence of the remote control.

7. This is the most environmentally friendly type of heating equipment, solid fuel combustion products almost do not pollute the environment, which cannot be said, for example, about natural gas combustion products.

Solid fuel heating boiler in the interior

But on solid fuel boilers reviews of experts are not always only positive, they highlight a number of shortcomings:

1. The need for regular manual loading of fuel (in cheap models – every 2-4 hours, in pyrolysis – twice a day).

2. The need for regular maintenance.

3. Regular delivery of solid fuel to the boiler and its preliminary preparation before loading.

Types and principles of work

These boilers can be classified:

1. By type of fuel consumed:

1.1. Traditional (they work on solid fuel: coal, wood, peat). If you want to use solid fuel boilers for wood, but coal, peat, etc. rarely used, choose special modifications that are best suited for this fuel. They will burn wood even 35% moisture.

Choose the height of the chimney depending on the power of the boiler and its internal dimensions..

Traditional solid fuel boiler – block diagram

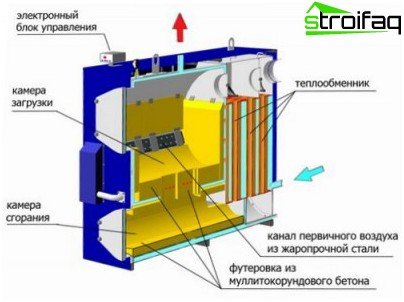

1.2. Combined or gas boiler with the function of pyrolysis wood burning. Their main difference from the traditional ones is that in addition to the firewood itself, wood gas can be burned, released by the wood under the influence of high temperatures. In the process of burning, a minimum of ash appears, soot does not form, but burns out together with heavy compounds. The main advantage of such boilers is a high 85% efficiency, as well as the ability to adjust power. But they are significantly more expensive than traditional ones, and only dry wood can be used. Among the manufacturers, the most famous Czech companies are Dakon, Atmos and German – Olymp.

The device of a solid gas boiler

1.3. Universal (can work on solid and liquid fuels, gaseous, as well as on electricity). They are very popular in Europe. Electricity is used through electric heaters built into the “jacket” of the boiler – electric heating elements. ElectroTENs are usually used at night in case of failure of the main firebox.

2. By functionality:

2.1. Single-circuit (designed only for space heating).

A single-circuit solid fuel boiler is built into the heating circuit only

2.2. Double-circuit (capable of heating the room and working on water heating thanks to the built-in hot water supply (DHW) circuit). A solid fuel double-circuit boiler is used for space heating, as well as for the preparation of hot water in an accumulative or flowing way. Accumulative – assumes the presence of a special built-in boiler up to 60 liters. Flowing – assumes the presence of a heat exchanger in the boiler, with which water is heated in a flowing mode. In a flowing way, hot water is prepared quickly, but we cannot talk about large volumes.

3. According to the material from which they are made:

3.1. Cast iron. Solid fuel cast iron boilers are usually equipped with one firebox, they are made of several sections, the number of which depends on the capacity of the unit. They have a long service life of 50 years, but often require repair, for example, replacing a burned-out section. Such boilers are heavy, they must be placed on a reinforced floor, they are more expensive than steel.

Cast iron solid fuel boiler – the most expensive, but also the longest-term option

3.2. Steel. Solid fuel boilers made of steel heat up faster than cast iron and more precisely support the specified mode.

They are equipped with a coil for heating water, and some models are equipped with electric heaters. Service life is 30 years. Disadvantages: in order to supply coal, the grate in them must always be changed to cast iron or water-cooled.

4. By the number of cameras:

4.1. Single-flow (there are both cast iron and steel). Single-boiler boilers need to be reconfigured every time, switching from one fuel to another, since the chamber parameters for each type of fuel are different. If you intend to use mainly firewood, then choose a spacious firebox.

4.2. Two-fuel (steel only). They do not need to be reconfigured when switching from one type of fuel to another, since there are separate wood chambers for gas or liquids. Such boilers are more efficient than single-boiler. Most often, they are universal with the possibility of installing electric heaters. Also, these boilers are solid fuel dual-circuit, always have a second circuit – an integrated broiler (like Bosch) or a heat exchanger.

A dual-fuel solid fuel boiler serves heating systems and hot water supply or two heating circuits

5. According to the method of fuel supply:

5.1. Manual method (in household models). Fully automated solid-state boilers for domestic use are not common, although active development is being carried out in this direction.

5.2. Automated (used only in industry). Solid fuel boilers industrial fully automated. They are not heated by firewood, but by wood chips, shavings, pressed saws. Equipped with a device such as a stoker or bunker burner. Stockker is a metal box equipped with a screw conveyor, adapted to supply fuel directly to the burner device, in which there is a boost fan. Fuel consumption is also regulated, and it depends on the temperature of the water. In Russia, such units are not produced, only abroad.

Solid fuel boiler installation

Installation of a solid fuel boiler must be carried out in strict accordance with the instructions, as well as safety standards. Sequencing:

1. Construction on the floor of a blank of non-combustible material, that is, a “platform” on which the boiler will operate. The base of the foundation should be 20 mm wider than the unit itself.

2. Installation of the boiler.

3. Connection of the boiler to the chimney.

4. Connecting the device to the heating system.

5. Checking equipment for defects.

6. The first test kindling.

When connecting a solid fuel boiler, it is necessary to strictly follow the manufacturer’s instructions and technological rules

Recommendations:

- The access distance to the boiler must not be < 1m.

- All flammable objects may be placed at a distance not < 25 cm from the boiler. And firewood, briquettes and other fuel – at least 40 cm.

- It is forbidden to heat the boiler with gasoline, kerosene, diesel fuel, glossy paper, scraps of laminate, particleboard, hardboard, as toxic substances are released when they are burned.

- The best fuel: dry firewood, peat, sawdust, coke or pellets.

- Inspect equipment regularly. It is necessary to remove ash fuel slag before each kindling.

- Clean the furnace and ash pan of the unit weekly so that the chimneys are not clogged.

With proper operation, these units are able to work for a long time and very efficiently. Solid fuel boilers are characterized positively by consumer reviews with long experience in operating these devices. People living in houses where such boilers are the only way to heat the premises, speak of them as reliable and durable heating appliances.