Solid fuel boilers

What to do to people living in non-gasified areas, because in winter you can’t do without heat in the house? Solid fuel boilers – a kind of prototype of the Russian stove, but at times modernized and improved. Progress is cardinal, since only the only common feature between them is the type of fuel. The principle of operation of such boilers is independent and autonomous, because they have no connection either with gas pipelines, or with electricity and a centralized heating system. These are undoubted advantages for remote villages, because people live there too and they need civilization.

Content

- The heart of the heating system

- Classification of solid fuel boilers

- Heat exchanger material type

- By the number of circuits

- According to the principle of work

- By type of automation

- By boot method

The heart of the heating system

Modern solid fuel heating boilers are considered to be excellent sources of heat and comfort in the home, a person can create any microclimate, regulate the temperature regime and not depend on communication services, which are sometimes damaged. And this is very wonderful: live in your own power (home) and rule the ball, that is, heating.

Quite often there are houses cut off from the benefits of human civilization, and yet the dwelling must somehow be equipped and live in normal conditions. Moreover, it is not clear when the communication benefits will appear. In this case, a solid fuel boiler will be an excellent purchase..

It is clear that coal and firewood are the main fuel of boilers of this kind. This suggests that people should take care of replenishment. In addition, it is necessary to equip a special room where this fuel will be stored, and it should be protected from precipitation.

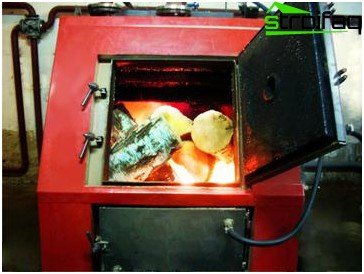

Boiler in action

Another nuance is that you need to monitor the boiler, because one portion of coal or firewood burns out and generates an amount of heat, then another and surely timely loading of fuel is required. There should always be a person in the house who will be responsible for the efficient operation of the boiler, because there will be several “tidings”, for example, one batch of fuel is designed for 3-4 hours.

You can extend the process of burning fuel, for this you should purchase a solid fuel pyrolysis boiler. When using it, not only the time of combustion of the fuel is prolonged, but also the efficiency and efficiency is increased. There will still be talk about his work in the article, but a little later.

And another advantage of solid fuel boilers is the “retraining” in gas (and suddenly the line still appears near the house), then you just need to change the burner.

Classification of solid fuel boilers

Such boilers have an important advantage – economical fuel: it can be coal, peat brackets, firewood, coke. Despite a kind of alienation from civilization, these boilers are fully equipped with an automation system, as well as equipped with sensors that are responsible for temperature, equipment safety.

Heat exchanger material type

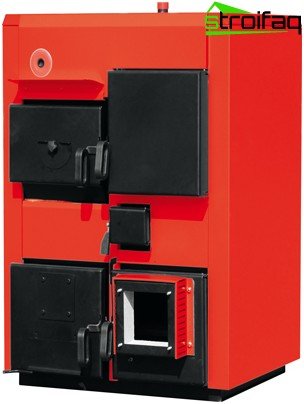

Solid fuel boiler

Solid fuel heating boilers are divided according to the type of heat exchanger material: steel or cast iron, while their fuel resources are identical. Solid fuel cast iron boilers are more durable, because this material has the property of heating for a long time and slowly cooling. But there are also negative points: such units are characterized by excessive fragility, which is due to sensitivity to sharp thermal drops. As a result of this “temperature shock”, the unit walls gradually collapse, and the boiler fails. Not everything is so bad, today the current technology has improved and cast-iron boilers have overcome fragility.

Steel boilers are more resistant to temperature “whims”, but they also have their own nuances – weakness to corrosion, and the reason for this phenomenon is condensation. Such an impact is not scary for a cast iron boiler, but in any case, the service life depends on the quality of the steel, the thickness and the fact of proper handling of the equipment.

By the number of circuits

– single-circuit boilers are designed exclusively for complete heating of the room. As a rule, in such boilers, the possibility of connecting a storage boiler is thought out;

Solid fuel dual circuit boiler

– solid fuel double-circuit boilers – one circuit is designed for heating, and the other, respectively, for hot water supply. A solid fuel hot water boiler can have different power, it can be calculated using the following ratio: 10 sq. m – a minimum of 1 kW of boiler power. But this is subject to a ceiling height of not more than three meters and good thermal insulation. And if the heat loss in the house is significant, then the hot water supply system must be appropriate.

According to the principle of work

According to this parameter, solid fuel boilers are divided into classic and gas-generating (pyrolysis). A solid fuel heating boiler operates according to the following scheme: the fuel is burned, and in return the heat carrier (water) is heated. Using a radiator system, heated water heats the room.

Important: in order for the classic boiler to produce rated power and high efficiency, it is necessary to ensure the correct functioning of the air exchange and the necessary draft in the chimney.

Pyrolysis boiler

When deviating from this recommendation, efficiency decreases, fuel is consumed, and the heater prematurely fails. Solid fuel gas generating boilers are based on the principle of pyrolysis combustion of fuel. The bottom line is: under the influence of high temperatures in conditions of lack of oxygen, wood (dry) decomposes into a volatile part, i.e. pyrolysis gas, and a solid residue, i.e. charcoal (coke).

Important: a temperature of 200 – 800 degrees is used for pyrolysis of wood.

This process is exothermic, going with the release of heat, air oxygen and pyrolysis gas are mixed, as a result, the latter begins to burn and is subsequently used to produce thermal energy.

It is desirable to heat the gas-generating boiler with the driest wood, as a result, it ensures operation at maximum power, as well as a long service life. What is the difference for the consumer between the classic and pyrolysis boiler? Yes, the fact that the time between downloads of the pyrolysis boiler increases at least twice. It should also be noted that the flue gases emitted from such boilers contain almost no impurities harmful to the atmosphere, by and large it is a mixture of carbon dioxide and water vapor. This means that they are more environmentally friendly and a small amount of soot and ash is formed in the combustion process (this argument is very pleasing), therefore, it can be cleaned less often.

By type of automation

– non-volatile – in such boilers, the air flow is regulated mechanically;

– volatile – air supply is regulated by a blower fan, which is controlled by an electronic unit.

By boot method

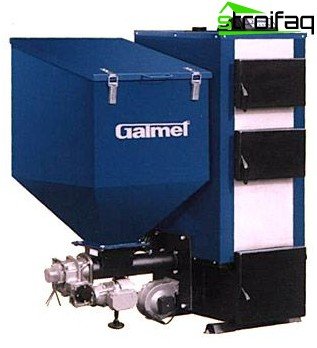

Hopper boiler

The method of loading fuel can be manual and with automatic feed (augers). The latter have gained great popularity in Europe, and this is not surprising, because they are characterized by huge advantages. That’s just not all consumers are available because of the high cost and inaccessibility of the type of fuel used – eco-peas. Other types of fuel can be used depending on the type of burner: coal with a fraction of up to 2.5 cm, pellets, dry wood chips.

A solid fuel heating boiler with a feed has a major plus – the hopper can be loaded and no longer need to go to the boiler for about 3–7 days (depending on the size of the hopper). In addition, such a boiler has a very high efficiency, minimal emissions, stable maintenance of the set temperature.

Important: for boilers of this type you need autonomous electrical power, a simple uninterruptible power supply is not suitable here.

Proper operation of solid fuel boilers

So, the dream came true and you became the happy owner of a modern boiler. How to handle it? Of course, you need to strictly follow the instructions and not take arbitrary actions.

A good solid fuel boiler is equipped, in most models, with a control unit, as well as a boost fan that maintains the coolant temperature.

The control unit for all the boilers considered in the article works according to one scheme: the temperature sensor is located in the boiler jacket, it sends a signal about the water temperature to the control unit. Therefore, if the temperature drops below the level set by the user, the control unit activates the boost fan, thus reaching the required temperature.

After reaching the desired mark, the fan turns off, and the standby mode, i.e. decay, is set in the control unit. In this mode, the fan is switched on periodically and for a short time to maintain combustion and remove accumulated gases in the combustion chamber.

Ignition is a crucial stage

Paper and small chips for ignition are laid through the fire door, and larger firewood is added through the loading door. If coal is provided for the furnace, then a little coal is poured over the stacked firewood. Then the paper is set on fire and time is given to flare up the chips. In the case of the recent operation of the boiler, a well-heated chimney and sufficient draft, you can close the door and simply turn on the control unit, while setting the desired coolant temperature. Then, after some time, the control unit should be turned off and the firebox door carefully opened to see for yourself that the stacked part of the coal has already ignited and you can add the main portion.

Important: while the gap in the front of the colossal grating does not close.

Now everything, the boiler itself will take care of maintaining the temperature. It’s just that low-quality coal can be coked, so it is recommended to periodically stir it or lay fuel according to the “sandwich” type – firewood-coal-firewood.

It must also be remembered that condensation may occur on the walls of the heat exchanger (inside the boiler) before the system completely warms up. This is often a temporary phenomenon, if the circulation is normal, then the condensate disappears.

Important: if the system and the house are cold, it is advisable that the boiler work for a while at a high temperature, and only then it can be reduced to the required level.

Ash removal is a must

Depending on the type of fuel, it is periodically necessary to remove the ash, which is located in the ash pan. There is less trouble with firewood, because the ash itself crumbles, and coal slags are a little more difficult to remove. But the game is worth the candle, because the duration of the boiler on coal at one load is 2 times longer.

Why do I need a circulation pump

A special device, a circulation pump, can be connected to the control unit. Why is it needed? Such a pump is necessary if the boiler does not gain temperature for a long time, for example, it runs out of fuel, then the anti-freeze mode is activated, and the pump periodically runs water through the system so that it does not freeze.

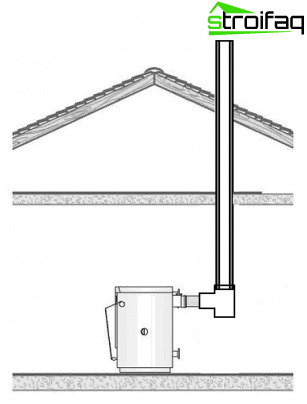

Chimney Rules

The installation of the chimney is a very important stage

Ideally, the chimney should be insulated, it can be a bricked brick or sandwich pipe. Its height should be at least 6 meters, while the cross section depends on the type of boiler. Not a single solid fuel boiler will be able to operate without a chimney, it’s not worth saving on its arrangement, this has a bad effect on the life of the boiler.

Solid fuel boilers are a great alternative for homes cut off from human goods. In summer, you can engage in the formation and purchase of fuel, and in winter enjoy the heat and not depend on anyone. The classic version heats the home, and solid fuel boilers, in addition to heat, also provide residents of the house with hot water, and this is also an important aspect.