Mixing unit for underfloor heating

The well-being of a person who is indoors is greatly influenced by the prevailing temperature regime. The optimal temperature for a person in a living room at a height of growth is +19 – (+20) degrees Celsius, at the floor +22 – (+25). The best solution in this case is the underfloor heating system, an important part of which is the mixing unit for the warm floor.

Content

- Purpose of mixing units

- Design of control valves

- The principle of the mixer

- Types of mixing units

- Management Options: Differences

Purpose of mixing units

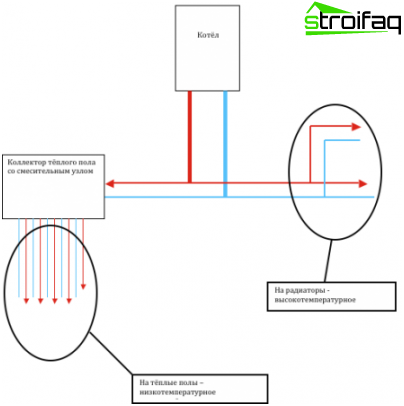

The mixing unit is used in heating systems. As a rule, a boiler room supplies water to the heating system, the temperature of which is approximately 70 – 90 degrees above zero, because it is such an indicator that is necessary for radiator heating. But the system of water heated floors is a low-temperature heating system, which requires a coolant temperature that reaches 25 – 35 degrees.

The mixing unit is designed to reduce the temperature of water by mixing a hot heat carrier with a return – a liquid that returned from the heating device and gave off heat. The kneading units are equipped with all valves, units and other elements that control and control the temperature regime.

In addition to underfloor heating systems, mixing units are widely used for the organization of panel heating – wall and ceiling, as well as for heating greenhouses and outdoor areas. However, the collector for the water floor is often used to stabilize the temperature of the liquid in the pipeline in the floor heating system in residential premises – in own apartments and private single-family homes.

Design of control valves

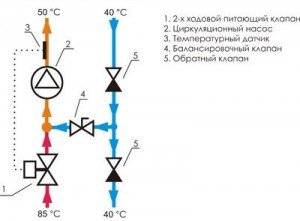

The collector for a warm water floor consists of such parts: a control valve (valve), a circulation pump, an electric drive of a control valve, ball valves, a check valve, a filter, a balancing valve and other fittings.

The mixing unit, as mentioned above, is designed to mix water from the return line. Regulation is carried out by a valve, which is installed in the feed manifold and thermostatic head, which has a remote immersion sensor. The balancing valve, which is located in the mixing line, sets the optimal ratio of the coolant that comes from the forward and reverse lines.

The collector for underfloor heating can be additionally equipped with zone thermostats and other measuring instruments, an air vent and a drain valve for draining water. A wide range of devices allows you to accurately calculate energy resources through the installation of a heat meter.

Brass and bronze are used as materials for control valves, un galvanized black steel for pipes, and cast iron for the body. Sealing is done using flax. The absence of zinc coating allows the use of mixing units where water-glycol solutions are used as a coolant, reacting with zinc.

The principle of the mixer

The pump runs continuously and provides coolant current in the pipes, and the valve passes the required amount of hot water of the programmed temperature at the right time. Thus, the required temperature level of the water heated floor is achieved..

The principle of operation of the mixing unit

Only the amount of coolant is regulated, therefore, underfloor heating never overheats, and rupture of the structure is impossible. Low valve capacity ensures stable, very smooth control of room temperature.

This is important to know! The floor temperature is of two types – comfortable and heating. The system of water floors in the first case creates comfort in the housing, and the energy consumption for their heating does not occur, this is achieved due to additional heating elements. In the second embodiment, such a floor also acts as a heating element, and the heating level will be much higher.

Mixing units are installed in the manifold cabinet at the very beginning of the installation of the underfloor heating system. Both left-side and right-side mounting of the mixing unit is possible. You can also perform a silent installation.

Types of mixing units

Mixing units for water floor heating are divided into several types. If you bought an individual collector, then you should remember that only one consumer is connected to it. If you select individual group nodes, you will be able to connect a consumer of increased power to them. It is also possible to connect several consumers with less power..

In the domestic market, there are also main mixing units for connecting several consumers, which are characterized by high power. Buyers are also offered heat exchange models. A small power consumer is connected in a closed circuit. There are models with a different number of outputs – from two to twelve.

Management Options: Differences

- Manual control is performed as follows: the mixing unit is used without any valves, manually set the percentage of mixing. But such a collector for a water heated floor is not customary to use for high-temperature heat sources, when the maximum temperature in the supply pipe is more than 50 degrees.

- The control in the temperature limiting mode occurs in this way: the thermostatic head with a remote type sensor must be installed on the directional valve. In the underfloor heating circuit, the temperature is limited in accordance with the set temperature on the head, which is supplied separately.

Modifications of control valves for underfloor heating with different control principles

- Outside temperature control is carried out according to this scheme: an electric actuator connected to a temperature regulator must be installed on the directional valve. In the underfloor heating circuit, the temperature is regulated in accordance with the temperature changes in the street. Electric drive and regulator are supplied separately..

Thus, if you decide to install a warm water floor system, then you should think about purchasing a mixing unit that will help lower the temperature of the water by mixing the hot liquid with the return. Different models are presented on the market, it all depends solely on the requirements of the heating system.