Fireplace inserts

It is advisable to use a fireplace for space heating from an aesthetic point of view rather than a practical one. Fire in the fireplace pacifies and harmonizes the psychological and emotional state with nature. The fireplace is the main decoration in the house, but in addition, it performs the function of drying the room and increases air circulation.

Most modern fireplaces consist of such parts: firebox, air distribution and smoke exhaust devices and claddings. Fireboxes for fireplaces are the main element, the heart of the fireplace, in which fuel is directly burned. There are fire chambers for fireplaces cast iron and open fireclay.

Content

- Open fireclay furnaces

- Cast iron fireplace inserts

- The advantages of cast iron furnaces

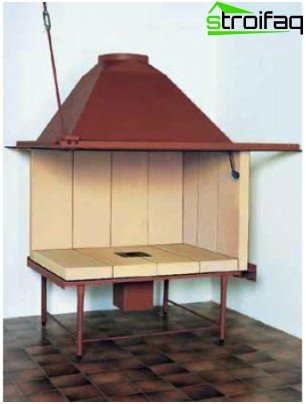

Open fireclay furnaces

These fireboxes are not built into the fireplace portal, they are one with it. In the manufacture of such furnaces a carefully polished fireclay refractory brick is used, which has an ideal shape. So that the bricks do not crumble and sprinkle, the seams between them make less than 3 mm. The walls of chamotte fire chambers should be perfectly even, this will ensure the correct reflection of heat into the room.

The performance of an open fireclay furnace depends on its design

The heat transfer efficiency of an open fireclay firebox depends on its shape. If the firebox has a vertical back wall and two parallel vertical side walls, then the heat transfer of such a fireplace is very low. Since only one back wall reflects heat. If the back wall of the furnace is tilted into the room, and the side walls are also deployed towards the room, heat will be reflected from all three walls.

Cast iron fireplace inserts

The cast iron fireplace insert for a long time preserves and “gives off” the heat received during heating

For the arrangement of wood fireplaces, cast-iron furnaces are sometimes used. Firewood burns inside the firebox, and the firebox retains heat in the fireplace. Such fireboxes can be both open type and closed. Today, more and more popular are fireboxes for cast iron fireplaces of closed type. They are a glass-metal module of various shapes: classic, radial, prism-shaped, tunnel, angular, architectural, non-standard. A fire is burning inside the module. The door opens either up or to the side..

The classic firebox has a glass front panel 1 m wide and up to 0.8 m high.

Semicircular cast iron firebox

Radial or semicircular furnaces have semicircular glass.

Prism shaped cast iron firebox

A prism-shaped firebox is prismatic.

Tunnel cast iron firebox

The tunnel firebox is equipped with a glass rear wall. It is very convenient if the fireplace has two rooms. From every room you can watch the fire.

Corner Cast Iron Firebox

Corner fire chambers have a corner frame and glass.

Architectural fire chambers can have a different shape: convex, concave, arched, elongated in width or height, as well as the shape of an ellipse or a full circle, with which a 360-degree view is achieved. Any non-standard furnaces are made to order.

The advantages of cast iron furnaces

- High thermal stability, do not deform at high temperatures;

- High rates of thermal conductivity and heat capacity;

- Strength of the material, resistance to burning;

- Continuous burning in such a furnace lasts longer;

- Long term of operation;

- Some models are equipped with a smoke-resistant layer on the glass, so that soot does not settle on the door.

The back wall of the furnace is made of cast iron with many protrusions. This design is somewhat reminiscent of the battery and increases the heat transfer area.

Between the furnace and fireplace trim there is a gap, which also plays an important role in heating. The wall behind the firebox is covered with heat-insulating material, the air between the rear wall of the fireplace and the firebox heats up and enters the room, penetrating through special ventilation openings.

Open fireplace

In a classic open fireplace, the firebox can be made of fireclay bricks, cast iron or steel. The efficiency of such a fireplace is not more than 30%, so they set it to decorate the room.

An open fireplace is beautiful, but its productivity does not exceed 30%

A fireplace with an open firebox requires a solid refractory foundation made of brick or concrete. It is absolutely impossible to install such a fireplace on a wooden floor. The floor in front of the fireplace at 0.7-1 m is also laid with refractory material. Most often it is a tile or stone.

It is necessary to install an open fireplace near the supporting (non-timber) wall in a large common room.

Compare the pros and cons

Advantages of open hearth fireplaces:

- Familiar beautiful appearance;

- Open fire;

- Any professional stove-maker will make a firebox out of fireclay bricks without difficulty;

- Relatively cheap option (you have to pay for a brick and stove work).

Disadvantages of open fireplaces:

- Small efficiency;

- Risk of fire or burns from open flames. Requires constant attention;

- If there are animals in the house, they can carry the ashes into the rooms;

- Over time, an open brick firebox must be sorted out and repaired;

- The choice of cast iron or steel furnaces of the open type is very small;

It may seem that there are many more shortcomings than advantages; this is not so. After all, everything is known in comparison. It is necessary to weigh all the pros and cons, prioritize, and if the efficiency of the fireplace is not critical, it is quite possible to choose an open fireplace.

Closed fireplaces

In such fireplaces, the combustion chamber has a closed shape and is made of cast iron or steel. One or more of the walls is made in the form of a glass door. There are models in which the door rises up and hides under the lining using a special mechanism. Thus, the fireplace becomes open. At the bottom of the furnace is another chamber: an ash pan. From it, air enters the combustion chamber. Correctly executed facing of such a fireplace hides all mechanical devices, and the fireplace takes on a completely traditional look.

The fireplace with a closed firebox is safe, does not pollute indoor air with burning and smoke

We appreciate the advantages and disadvantages

Advantages of fireplaces with a closed firebox:

- Large selection of furnaces of various models;

- Efficiency is higher than that of a fireplace with an open firebox;

- The service life is longer than with a fireclay brick firebox. It is possible to replace burnt parts without dismantling the firebox;

- A greater indicator of fire safety, as there is no open flame;

- The ashes are not carried around the house, as it is going to an ash pan;

- There are modules that simulate fireclay bricks..

Disadvantages of fireplaces with a closed firebox:

- There is no open fire, it is behind glass;

- If the furnaces are cheap, then the overview is small, the glass is small, it must often be cleaned;

- Installation of a cast iron firebox requires special knowledge and skills;

- The high price of quality models.

This type of fireplace is ideal for heating a room without the risk of fire. Cladding can be made as reminiscent of a traditional fireplace, and sometimes used with the door open, enjoying the game of flame.