Aluminum heating batteries (radiators)

Aluminum heating radiators – This is perhaps the most common type of radiator in Russia. Usually they are put instead of cast-iron batteries, which were the main heating appliances in the Soviet era. In many respects, the priorities of the Russians are clear: aluminum radiators have several advantages compared to cast-iron counterparts, which are hopelessly outdated. Next, we will cover in detail all the issues related to these heating devices, talk about how to properly install them.

Content

- Technical characteristics of aluminum appliances

- Reviews and assessment of specialists

- Calculation of the number of sections

- How to calculate power

- We calculate taking into account heat losses

- Recommendation – Install thermostats

Technical characteristics of aluminum appliances

Aluminum radiator can be made in 2 technical options, namely:

1. Cast method. Sections of such an aggregate are monolithic, integral parts. They are made under pressure of aluminum alloy by casting..

2. By extrusion method: the profile is squeezed out on the press, after cooling it is cut into the required dimensions, the bottom and top parts are welded to it. Sections are interconnected mechanically by means of sealing elements or by means of adhesive joints.

Cast radiators are more reliable and high quality compared to extrusion ones. Technical characteristics of these 2 types of heating devices can vary in the following ranges:

1. Distance between axles: 350 – 500 mm

2. Maximum working pressure: 6-16 (sometimes up to 24) atm

3. Dimensions (height / width / depth): 380 – 590 mm / 80 mm / 81-100 mm

4. Thermal power: 82 – 212 W

5. Weight of one section: 1 – 1.47 kg

6. The maximum temperature of the heat carrier (usually water): 110 gr. FROM

7. Water volume in 1 section: 0.25 – 0.46 l

8. Warranty: 10 – 20 years

Important! The weight of one section of a high-quality aluminum radiator cannot be less than a kilogram, and the weight of a 10-section radiator cannot be less than 11 kg (including connecting nipples).

Reviews and assessment of specialists

Specialists in the field of heat supply note a number of advantages of these heating devices:

1. Very high heat dissipation. Aluminum batteries emit about 50% of the heat through radiation and another half with convection. Additional fins located inside the section also increase heat transfer..

2. Well regulated with thermal heads, so the volume of water in them is relatively small. Using a thermal valve saves up to 20-30% of heat resources.

3. Light weight. This factor greatly facilitates installation work..

4. Low price compared to all other modern types of radiators.

5. Elegant design, diverse design solutions.

6. Working pressure (mainly up to 16 atmospheres) – the most optimal in conditions of private houses and typical buildings.

The list of advantages reasonably explains why aluminum radiators are so popular and in demand among the population. But they also have certain disadvantages:

1. Durability, tendency to corrosion. Aluminum is an active metal, therefore radiators from it can work for a long time and effectively only in the presence of a heat-transfer agent of a gentle composition. In particular, at a pH of the composition of the coolant is 7–8. Solid particles that can destroy the protective layer on the inside of the appliance are dangerous for aluminum pipes. If the water in the heating pipes undergoes special training, this can significantly extend the life of such radiators.

2. Need periodic removal of air from the upper pipe using an air vent valve.

3. In extrusion aluminum radiators, threaded joints of sections are the least durable places, therefore it is not recommended to use them in houses and in factories with sufficiently high pressure in the heating system.

On a note. Do not confuse aluminum radiators with devices such as copper-aluminum heating radiators. These are completely new developments. They are a non-separable structure in which horizontally arranged copper pipes are connected to aluminum plates placed vertically. Cold air is drawn in by such units from below and leaves heated through the upper grill. 80% of the heat it gives off by convection.

Calculation of the number of sections

For each room, it is necessary to choose the optimal number of sections, taking as a basis the area of the room and the heat transfer of one section of an aluminum radiator.

Consider the following factors when calculating:

- climatic conditions of the region;

- possible heat loss;

- coolant temperature (usually water);

How to calculate power

The power rating of 1 heating battery should be 150 watts per square meter.

The thermal power of aluminum batteries can vary between 82 – 212 W, depending on the model of the heater and its manufacturer.

Accordingly, if you need to heat a 10-meter room, for example, in a room located in the middle zone of Russia, then it is advisable for you to buy a 9-10-section radiator with a capacity of one section of about 100-110 W or a 5-section with a section power of 200 W.

We calculate taking into account heat losses

Heat losses, which are mainly affected by residential premises, can be divided into those that occur due to heat leaving the window through the walls, as well as heat losses that occur along the way to the batteries. Also keep in mind that:

- up to 75% of heat can go through the windows (depending on the quality of the profile);

- the largest heat losses occur in corner rooms;

- in a room with 2 windows there is always more heat loss, therefore, sections of an aluminum radiator should also be installed there;

- if you regularly ventilate the room in winter, take radiators with a margin – 1-2 sections more;

- when the temperature of the coolant is less than the temperature necessary for heating the room, it is advisable to install more sections by 10-30%;

Important! When calculating sections, proceed from the rule: excess heat is much better than a lack. Winters can be unpredictable, in central Russia there is a high probability of frosty winters. Therefore, the calculation of the sections of aluminum radiators is best done with a margin.

Recommendation – Install thermostats

If the means do not allow you to do this, then try to get at least a bypass tap and a tap that shuts off the water supply. If you turn off one tap halfway and close the other completely, this will allow you to smoothly control the heat transfer of the battery.

Installation of aluminum heating radiators

Aluminum radiators are operated only in 1 and 2 pipe heating systems, in which the heat pipes combining the heating devices are located vertically and horizontally. Aluminum radiators can be used in pumping (where forced circulation) and gravity heating systems (where natural circulation).

Reinforced aluminum radiators with a pressure of more than 12 atm are suitable for use in systems with central heating, but they can also be used in stand-alone systems. Standard radiators of the European type are suitable only for an autonomous heating system, since their working pressure (usually 6 atm) is not enough for use in central systems.

Before mounting the radiator, you need to consider:

- Correspondence of its technical characteristics to the parameters of heating mains. These data can be found in the housing department.

- Installation location: under a window, on a wall on brackets, or at a window or wall on racks.

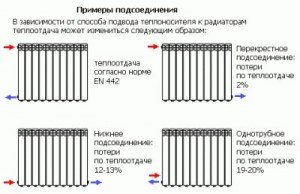

- The method of connecting heat pipes. They can join on the one hand and from the opposite. If you chose a one-way connection of radiators, then you should not excessively increase the number of sections. If you plan to use more than 12 sections in one radiator, then connect to the heat pipes from different sides.

- Minimum distances: from the wall – no more than 2-5 cm; from the floor – no more than 10-12 cm; from the windowsill or upper niche – 10 cm.

- Installation of thermostats at the inlet / outlet of radiators.

- Pre-flush the heating system.

Important! In single-pipe heating systems of high-rise buildings, thermostatic valves are not installed on radiators in the absence of a special jumper between the return pipe and the supply.

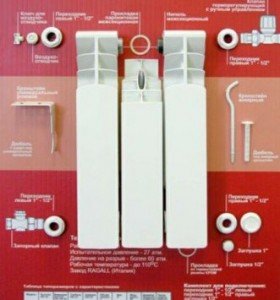

A radiator kit usually includes:

- air exhaust valve;

- adapters;

- stub;

- gaskets;

- brackets;

- section extension nipples.

Installation sequence:

1. Marking the installation site.

2. Fixing the brackets to the wall.

3. Installation of the radiator on the brackets: conditionally horizontal elements of the radiator heads located between the column sections should lie on the hooks of the brackets.

4. Connection of the radiator with heat pipes equipped with a thermostatic valve, tap or valve.

5. Installing an air release valve, plugs.

Important! Each aluminum radiator must have a manual or automatic valve designed to release air.

The aluminum radiator should be installed as accurately as possible, in accordance with the SNIP, in the season preceding the heating season. Especially carefully monitor the quality of the unit’s connection to the heat pipes to avoid leakage of the coolant.