How to make peaks and canopies

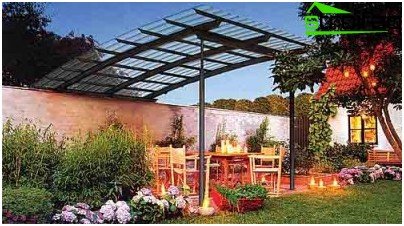

This element of the house and the infield is familiar to almost everyone. It’s about the easiest protection against rain and snow! It is provided by canopies made of polycarbonate, photos of which speak of their diversity. Having such a shelter, you can hide from the weather and at the same time do not cease to admire nature and breathe fresh air.

Content

- Advantages and disadvantages of this coating.

- Drawing up drawings and estimates.

- Canopy manufacturing technology

Among the many materials from which canopies are made, polycarbonate is famous for its special achievements. About how to make such a device out of it and will be described in our article.

Advantages and disadvantages of this coating

If you decide to make your own polycarbonate canopies, you need to know the strengths and weaknesses of this unique and relatively inexpensive building material.

The advantages include the following characteristics.

- High strength. Such a coating can withstand heavy loads from impacts (for example, hail). Its strength is provided by a special protective film that performs the function of armor. Therefore, when buying, pay attention to this nuance, so as not to purchase material that does not have protection (there is one).

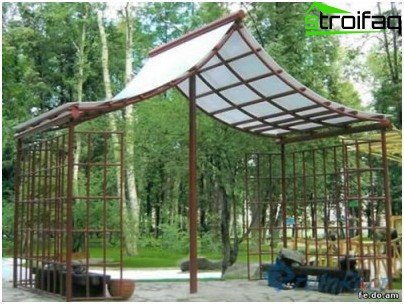

- Flexibility. Thanks to it, you can make the most original in the form of visors and canopies made of polycarbonate, up to the dome.

- Ease. This is a very important feature that makes it possible to do work without assistance..

- Incombustibility. It withstands very high temperatures, and in case of fire it does not ignite, it only melts.

- The ability to transmit light well. This quality allows its use in the construction of greenhouses..

- High thermal conductivity. Due to the honeycomb structure, there is the ability to perfectly retain heat inside greenhouses or other rooms.

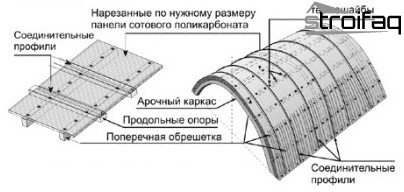

The main elements of the construction of the canopy

After you learn about the properties, you may have the impression that polycarbonate is the ideal material. But here there were some shortcomings. How can he upset his master?

- High coefficient of thermal expansion. Under the influence of high temperatures, it expands greatly. Therefore, when solving the problem of how to make a polycarbonate canopy, do not forget about expansion joints.

- Easy to scratch. The susceptibility to abrasion is so strong that even from the constant presence of dust, the outer surface becomes dull. Because of this, the light transmittance of the protective elements is lost..

Knowing all the advantages and disadvantages of the material, you can move on to the question of building small architectural forms with your own hands.

Drawing up drawings and estimates

It is worth recalling that this stage in construction is a must. Remember that the speed and ease of installation will largely determine the correctness, clarity and accuracy of the design. Canopies made of polycarbonate, the drawings of which are made competently, as a rule, cost owners less.

The need for a project is not a whim of an architect or designer. It is made up for convenience, in order to correctly determine the design of the element, its purpose, dimensions, amount of work, total costs, etc. The project includes a drawing, an estimate for the cost of work and materials, etc..

Without a drawing it is difficult to imagine the final result and calculate costs

Owners of houses who do not dismiss seemingly unnecessary “drawing” and elementary mathematical calculations always win. Having given it just a few hours, you can really imagine the expected result. After drawing up the project, you can proceed directly to the construction.

Canopy manufacturing technology

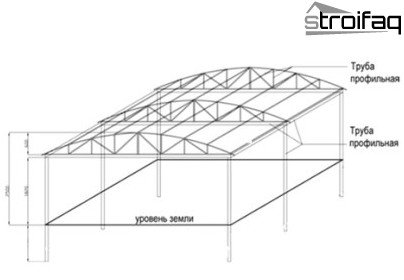

- First of all, you should make a metal frame for a canopy of polycarbonate. This will require the services of a welder, since it is made of a profile pipe. It can be of different sections – rectangular or square.

The most difficult thing is the manufacture of a metal frame

- The basis for fastening the sheets should be done taking into account certain rules. First, they need to be mounted on a pipe. Therefore, the supporting pipes must have a pitch corresponding to the width of the sheets of material. When you need to make small canopies, this requirement can be ignored, since then only a small part of the sheet is used. An example is a polycarbonate canopy above the porch..

- Fastening the coating itself to the metal frame is quite simple, but you need to do it firmly and reliably. To fix the material, metal screws with press washers are used. Their device helps prevent rainwater and melt snow from getting under the canopy..

- Another important point in the manufacturing process of such small forms is the correct joining of individual parts of the material. For this purpose, use a connecting element in the form of a strip of plastic. It has a two-sided groove into which the coating material will be inserted. Such a connector simultaneously creates a hidden expansion joint. The manufacture of canopies made of polycarbonate provides for the following conditions – the material should not completely rest in the grooves of the connector. It should have a gap that will minimize the consequences of changing its size during thermal expansion (bloating or cracking).

- In the process of erecting such a mini shelter, it is worth paying attention to one more moment. It is necessary to close the ends of the material so that the appearance of the product does not deteriorate due to dust and dirt that can get into the polycarbonate cavities. To do this, there is a special starting strip, made in the form of the letter “P”. Depending on the design of the canopies made of honeycomb polycarbonate, it is either glued to the sheet or tightly screwed to the frame.

In conclusion, we want to draw attention to some of the nuances that you need to consider when buying polycarbonate. The presence of a protective film was said earlier. In addition to it, it is important to choose its thickness correctly, which happens to be 4.6.10 mm. If the canopy has steep slopes, then fine material is fine. Flat slopes must withstand snow layers, therefore they need a thicker version (at least 6 mm).

You can proudly present the fruits of your labor

You already understood that country canopies made of polycarbonate can be made with your own hands. If you do not have the opportunity or desire to resort to welding, then a tree can become the basis for your protective shelter. We wish you a successful work!