You will probably agree that the word “typical” is increasingly giving way to the word “individual”. This applies to all areas of our lives. We want to differ from each other not only in clothes and brand of the car. Our personal preferences should be visible in everything, including, it would seem, not so significant gates for giving. Although they can tell a lot about those who open and close them daily. The way they look reflects the artistic taste and social status of people living outside the fence. How to choose and build a beautiful and solid gate?

Content

- How to choose the best option

- Material selection

- Sizing

- Choosing a way to open

How to choose the best option

These protective and enclosing elements are divided according to

- the material from which they are made;

- size or size of the structure;

- the way in which they will open and close.

Let us dwell in more detail on each of them..

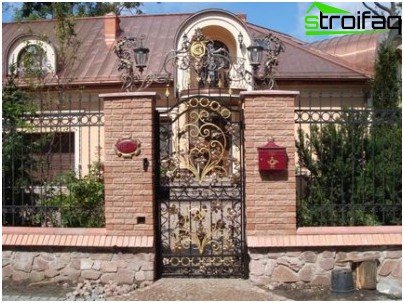

Such an entrance to the house is equivalent to a business card

Material selection

To choose the right material for the gate, you need to take into account the style of the entire building. It should be in harmony not only with the fence, but also with other buildings. In this regard, wood and metal products can be considered the most universal. Such materials are perfectly combined with one another and are in perfect harmony with brick and stone buildings. In addition, they have been proving their reliability for a long time..

The gate must be in harmony with the overall development

If we talk about the price, then compared to other wooden gates will cost less. But this in no way reduces their dignity. For example, if you order a designer gate made of wood, you will have a real work of art. Since such a product is made in a single copy, then its price will be appropriate.

Forged gates and gates for giving will cost even more, but their price is justified. Due to their reliability and impeccable appearance, they have long been popular. If you want to have a unique face of a country estate, then think about this option. Forging in combination with wood, stone and even bricks looks especially advantageous.

Products from combined materials look particularly impressive decorative finishes.

Strength and durability are famous for wickets made of corrugated board. If proper care is provided, then wood products can also last a very long time. For gates can also be used mesh netting on the frame, plastic and metal rods.

Sizing

The width of the gate is determined taking into account the type of transport that will enter through them into the territory. For cars it will be enough to have an opening 2.6 meters wide. Gate with an increased size of up to 3.4 meters can ensure the entry of a truck. The height is not strictly regulated, but determined depending on the design features of the product. The bottom edge should be 15 cm from the ground to open easily after snowfall. The standard-sized wicket is 1 meter wide, although reasonable derogations can be made if necessary. The height is made at the level of the fence or slightly higher, which often occurs due to the decorative finish.

Choosing a way to open

As a rule, wickets are made oar. The gates can be very different – oar and sliding, lifting and sliding. An automatic mechanism is often used to facilitate opening and closing the gate leaves..

We build a gate with our own hands

Materials and tools

Of course, in the absence of choice, you can use boards of any tree species. However, experts advise giving preference to oak, larch and cedar. A very important condition for a long service life is the pre-treatment of the material with an antiseptic. It will protect the tree from subsequent rotting and destruction by insects. If the boards are prepared in advance, then the gate will be able to maintain its appearance for 10 or more years. An ordinary picket may be suitable as a finish.

Before starting work, everything necessary should be prepared in advance, since the absence of the most insignificant can suspend installation work. So, getting started, worry about these materials and tools:

- boards and picket;

- door handle, latch, hinges;

- corners and screws;

- level, rope, emery;

- drills, jigsaw, screwdriver;

- a chisel and a plane;

- hammer and hacksaw;

- a pencil.

From the tree you can make the most bizarre shapes

Gate manufacturing technology

- We measure the distance that will be between the supports – concrete, metal or wooden poles (the main thing is that the material is durable). They should hold the frame of the future gate. The correct operation of the finished product will depend on a well-calibrated distance. For precise fixation, the pillars are laid on the ground and fastened together with the help of improvised means. For wooden supports it can be a picket fence, but for metal and concrete, wire is suitable.

- We install the posts. For this, two pits are excavated with a depth of 80-100 cm. For stability of the supports, pebbles, gravel or broken brick are poured onto the bottom of the pits. When installing poles, you should take care of the small distance between the lower crossbar of the product and the surface of the earth. It is necessary for the free opening of the gate. Vertically placed poles are fixed with spacers and poured with a mortar prepared from a cement-sand mixture. Before proceeding to the next step, you must wait until the solution completely hardens. If you dig pillars into sandy soil, then the distance between the supports must be concreted. At the end of this step, door hinges are attached and welded..

- Doing the door. First you need to make a base frame. To do this, four boards are fastened together with the help of corners. Then fasten the hinges and check how the frame fits into the opening. If everything is fine, then you can proceed to suturing the frame with a picket fence.

- We fix the handles and latches. This work is done at the very end. The top of the picket fence can be flat or cut off in the form of a zigzag or wave. This requires a jigsaw.

- We hang the finished gate on the supports. With proper calculation, it moves without any effort. A strip of thick rubber is attached to it from the free edge..

So, you got acquainted with how to make the basis of the most elementary gate. In the future, it can be varnished and decorated with any decor. There is an opportunity to show your imagination and skill. We want your gate and gate to serve for many years.!