The order of construction of the gazebo made of metal

A self-made metal gazebo has high strength and durability, while the design looks quite easy and is suitable even for a small garden. There are collapsible and capital structures that are assembled with bolts or self-tapping screws. Another popular option for attaching structural elements is welding. A metal gazebo is a great option for those who want to place a barbecue or fireplace inside.

Content

- Features of the placement of metal arbors

- The simplest design option

- Installation of the base of a stationary metal gazebo

- Installation of the frame and roof of the structure

Features of the placement of metal arbors

The best place to install the gazebo will be a quiet and cozy corner of the garden or a green place near the pond, surrounded by shrubs or flowers. It is good to think over a cobbled path that eliminates the need to walk on the soil moistened after rain to the building. Ideally, if the location of the gazebo is away from the road, then exhaust fumes and noise will not spoil the rest.

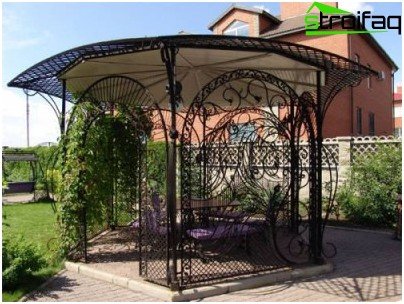

Thinking over the location of the structure, you should try so that the view from it opens up attractive, for example, on an alpine hill or pond, and not on outbuildings, a garage, a gate or a building facade. The buildings look beautifully, the walls and entrance of which are decorated with climbing plants (honeysuckle, girl’s grapes, clematis, climbing roses, honeysuckle and others).

Successfully fit into any landscape solution arbors twined with climbing plants

Pergolas of any shape, design and size fit well into the large garden. For a small garden, not all options are good, because a bulky structure can easily disrupt harmony. However, this moment least affects metal gazebos, because they do not crush with their mass, they look light and elegant. It must be understood that the design must be strong and stable..

High-quality assembly and a flat area are a prerequisite for creating a durable building. However, in case of soil subsidence or temperature changes, the rigidity of the frame will save the structure. Such arbors have their own important drawback – this is a strong heating of metal elements by the sun..

The simplest design option

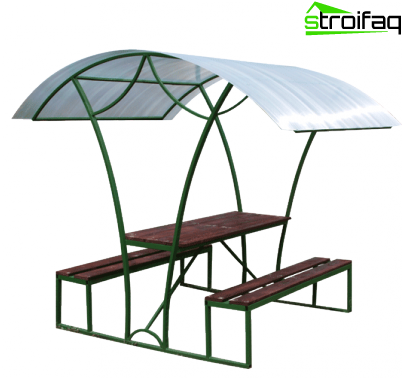

The simplest construction of a metal gazebo, which you can build yourself on the site, is a prefabricated structure from a profile on bolted joints. In this case, round or rectangular pipes of different sections, angles, channels, I-beams, square or hexagonal rods are used for filling. A welding machine is often used and, using spot welding, the structure frame is assembled..

Such a simple and uncomplicated arbor with a bench and a table can be made with your own hands..

The most popular are round, rectangular, hexagonal and octagonal arbors. Other forms are less commonly used, but are sometimes needed to implement certain design ideas..

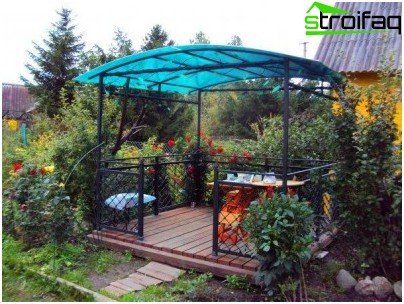

The care of metal arbors is moderate. It is important to periodically inspect the building and tint it in the spring to update the appearance, and in the fall to create additional protection for the cold season. This applies to stationary buildings. However, there are temporary structures that are installed in the warm season, and then disassembled and stored until their next use. Of course, they also periodically need to be inspected and the paint layer updated. For such arbors, you do not need a floor and base device.

Such collapsible octagonal designs do not require installation of the base and floor

If you wish, you can bring electricity to the metal gazebo. It is important to choose devices that are designed for use in humid conditions with the likelihood of significant temperature changes. They must be mounted tightly or semi-tightly. The wires should be hidden in a corrugated sleeve, the wiring should be carried out using a cable with double insulation suspended on a thin cable.

Installation of the base of a stationary metal gazebo

For a major building, you can level the soil, install a concrete platform or raise the gazebo on piles or piers above ground level, the entrance in this case will be slightly raised. The latter option is good, as it will provide the building with an appearance of lightness, and also protect the base of the structure from moisture, so it saves a little money (no waterproofing is needed).

If desired, a wooden or concrete floor can be built in the gazebo

In any case, for the capital structure, it will be necessary to install pipes to which the main racks of the frame will be welded. To do this, pits are excavated in the corners of the future building and concreted (the verticality of the installation is checked by the level). Then, if desired, a concrete or wood floor is arranged. If a concrete base is selected, the process of its construction is as follows:

- a wooden box of boards is installed around the perimeter, which are supported on the outside by pegs, which allows the concrete mass to be in the designated place for it;

- a layer of sand is poured over the soil and watered with water, then it is compacted; if the area exceeds 1.5 – 2 m2, it is important to make temperature shrink seams;

- thin boards are placed through each meter, between which concrete mortar is poured;

- after the concrete has set, the boards are removed, and the cracks are sealed with mortar or liquid concrete.

Installation of the frame and roof of the structure

At the very beginning of the work, it is advisable to draw a drawing and calculate the necessary number of pipes for the frame, additional couplers, runs, etc. In order to save money, any additional elements can be taken smaller.

To build a gazebo requires such tools and materials:

- Bulgarian;

- drill and set of drills for metal;

- welding machine;

- building level;

- pipes for the frame (optimally square or rectangular section);

- paint on metal (for better adhesion, you can first apply a primer);

- roofing material;

- screws.

The installation of the frame of a stationary gazebo begins with the fact that the supporting racks are welded to pipes previously dug into the ground, and then horizontal pipes are mounted to them at the top. Depending on the size of the building, crossbars are added to the resulting structure, additional racks.

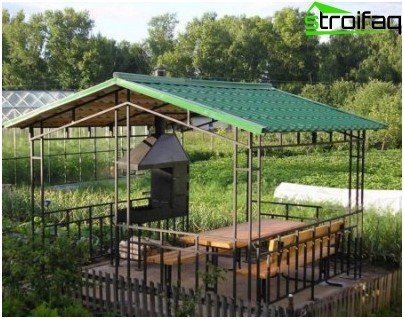

A great option for a metal gazebo with barbecue and garden furniture inside

Pergolas made of metal can be sheathed outside with various materials, this will protect the relaxation area from rain and gusts of wind. Inside such a structure, it is easy to place a barbecue, fireplace, barbecue. After the frame is completely ready to begin installation of the roof. It is made of ondulin, polycarbonate, slate, profiled flooring, etc. Fasteners are carried out either by welding, or by using screws.

Making a metal gazebo yourself is not difficult in principle, especially if you have the skills to work with a welding machine. This design looks impressive, it is durable and practical. If desired, in the gazebo you can organize a comfortable relaxation area with barbecue, garden furniture and even spend electricity there..