Do-it-yourself water well

If no water is supplied to the summer cottage (sometimes it happens), then you need to do it without fail, because you can’t do it without water. Among the most popular methods of obtaining water in a country house is a water well. This is a rather interesting and rational method, because a water well with your own hands is a double benefit: saving money and producing high-quality drinking water.

Content

- Signs of clean drinking water

- Types of water wells, their differences

- Water “in the sand”

- The limestone well

Signs of clean drinking water

Since the well on the site is equipped with the aim of extracting clean water from the bowels of the earth, it is necessary to know by what parameters this “cleanliness” is determined:

- a layer of transparent water not less than 30 cm;

- nitrate level – not more than 10 mg per l;

- less than ten Escherichia coli per liter of water;

- assessment of smell and taste – 3 points.

To obtain reliable information about water quality, it is necessary to conduct an examination in the sanitary-epidemiological service.

Types of water wells, their differences

Groundwater is mainly found in two rocks: sand and limestone. Also, in a bound state, its content in clay and loams is observed, but water production from these rocks for domestic and industrial use is extremely small.

Therefore, domestic water is extracted from wells with a face in water-saturated sand or in fractured limestone.

Water “in the sand”

Such water wells are most often equipped at the site with people who are quite satisfied with the use of 0.5 cubic meters of water per hour (for cooking and watering in the summer). Typically, the depth of such wells varies between 10-35 m, less often – 40-45 m.

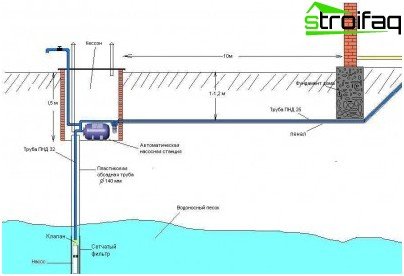

Schematic arrangement of the well

Drilling of wells “on the sand” occurs before the first aquifer and does not exceed two days. The durability of such a well depends on the pumping equipment and the reliability of the casing mesh. With proper use, the water well will faithfully serve up to 15 years, but with increased intensity of operation, this period is reduced to 8 years.

Casing pipes (made of galvanized or ferrous metal) are used for drilling a well “on sand”; they are interconnected by a threaded joint or by welding. Another filter pipe is required, it duplicates the casing string from the inside. The diameter of the filter pipe is smaller than the diameter of the casing, and at the end it has openings through which water enters the surface. The hole is equipped for cleaning water from sand with a special filter (from a metal mesh). But if the well will be used periodically, then after several years the filters will clog with sludge and they will need to be replaced.

Since the source of water supply in such a well is the upper aquifer, the water may not have purity and high quality indicators. Therefore, 3-4 days after drilling a well, it is advisable to pass a sample for bacteriological and chemical analysis.

Benefits:

- low cost of drilling;

- quick and easy installation of equipment required for installation.

Disadvantages:

- uncertainty about the exact location of the aquifer. In neighboring areas, you can easily find water in the sand, but in your own it may not be;

- probability of aquifer contamination;

- shorter life when compared with an artesian well;

- groundwater level fluctuation.

The limestone well

The best option is to drill an artesian well before upgrading the site or before starting to build a house, since drilling equipment and related equipment take up a lot of space. The equipment of the artesian well takes about 1-2 weeks, and drilling is carried out until the aquifer in the limestone is reached (50-200 m).

The life of such a well will depend on the quality of the casing, and productivity depends on the diameter of the pipe. Metal-plastic pipes are quite popular today, although steel pipes are also used. Steel pipes are joined by welding or threading. But welding is not the best option, because at the joints there is a high probability of corrosion. Also an undesirable phenomenon is microscopic holes, which nevertheless remain with a welded joint, they gradually increase, which means that a path is opened for dirt to enter the water.

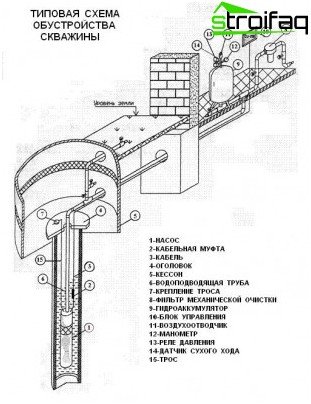

Artesian well diagram

A drilled artesian well is washed before the appearance of visually clean water, and a passport is also compiled for the “limestone” well indicating the depth, height of the water level and other basic characteristics.

Advantages of such a well:

- approximately known depth in advance;

- very high water loss. An artesian well can provide water for a country house with a pool, a sauna and several bathrooms, and it can also be used for gardening;

- durability;

- constant level of water;

- installation of a high-performance pump;

- high water quality, since at great depths, water is practically not exposed to the negative effects of pollution sources. Therefore, artesian water does not require additional disinfection and purification.

Well, the disadvantages can be attributed only to a more tangible cost of the entire spectrum of work, and it is impossible to do it with one’s own hands because of the hardness of the dense sedimentary rock and the considerable depth of occurrence. Water extracted from an artesian well can have a fairly high salinity. Therefore, despite the apparent purity, laboratory studies of its composition are necessary.

Wellbore casing pipes

The casing for the well ensures the integrity of the channel through which water is transported from the underground. Moreover, the integrity should be ensured throughout the entire period of operation, which means that the pipes should not give in to corrosion and be resistant to dynamic loads during casing. At present, steel, asbestos-cement and plastic pipes are used as casing pipes..

The use of steel pipes is an excellent solution for large and demanding projects, when the depth of the well is large and the geological conditions are complex. Of course, the larger the drilling depth, the correspondingly increases the pipe wall thickness.

Metal pipes for casing

Pipes made of polymer are often used in areas with uncomplicated geological conditions when drilling in shallow depths. Plastic pipes can be used for casing up to 10 m, they provide excellent corrosion resistance, and the project itself will not require significant financial investments.

As for asbestos-cement pipes, they have a number of positive characteristics: the well will not corrode and “grow”, and their price is very attractive. But there are specific limitations – this is a fragile material that does not withstand excessive hydrostatic pressure, so only shallow wells should be equipped with such pipes.

Important: savings are inappropriate here, because no one needs additional costs for re-drilling the well.

Equipment for arranging the source

A narrow and long hole in the ground is not yet an autonomous source of water supply. In order for the water to become potable, the well must be equipped. The following equipment is provided for wells:

- caisson – it is necessary for servicing the water source, it protects the pipes from freezing, in addition it is a kind of bunker for installing equipment;

- wellhead – a cast-iron or plastic construction that prevents contaminants from entering the well through the wellhead;

- pump – pumps water;

- hydraulic accumulator – smoothing hydroblows and maintaining pressure in the system.

Typical Well Equipment

The arrangement of the well is an important process, because its functionality depends on the quality of the selected equipment and competent installation.

How to drill a well with your own hands

The artesian water is undoubtedly very good, but if there is no money to equip the well to get it, then you can use the money-saving option and do the drilling of your own hands. This is a difficult task, but quite feasible..

The design of the well is determined by the number of casing strings lowered down, their dimensions (length and diameter) and space cementing intervals.

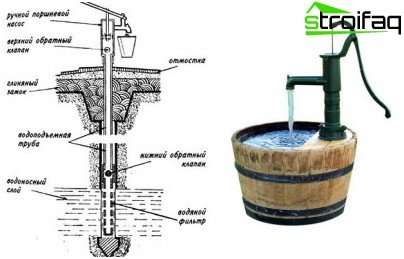

So, a do-it-yourself well begins with digging a pit – sizes 1.5 to 1.5, depth about 2 meters. This stage is necessary to prevent the topsoil (very fragile) from shedding. The walls of such a pit are lined with boards.

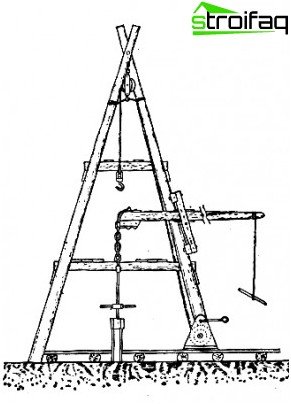

Well Drilling Rig

The next stage is the preparation of the rig and the column. Most often, a tripod is used as a derrick. It is made of logs (diameter 15-20 cm), between which a winch is fixed.

Drill string – six or more rods that extend each other by means of adapter couplings, as a result it has the appearance of a single pipe. The column is completed by a tool lowered to the bottom – a drill head, the form of which depends on the type of soil. As a drill head for excavation, you may need:

- coil;

- a bur-spoon is used for cohesive clay soils (sandy loam, loam). For one notch, it deepens by 30-40 cm;

- drill – a chisel designed for hard soil;

- bailer – for the extraction of sand saturated with water, gravel, pebbles, crushed stone with sand aggregate, drill loose mud. It happens simple, pneumatic, piston, clamshell.

Then it is necessary to connect the first drill rod with a cable thrown over the winch, attaching a drill head to the end of the rod lowering to the bottom of the rod. The rod with the head must be immersed in the place of the proposed drilling. As they go deeper, the second joins the first rod, then the others sequentially. Depending on the soil on the face, it will be necessary to change the drill head during drilling.

Important: on the rod before starting the drilling process, it is necessary to make a mark at the level of 60 cm. When this mark is reached, the drilling tool rises and cleans.

Well drilling should be carried out by two people, so the work will go faster and more comfortable. Drill until reaching the water-resistant layer. Then the well is thoroughly cleaned.

Then a filter is lowered to the bottom of the well, the remaining space is filled up with coarse sand, fine gravel. After that, you can proceed to the refinement of the shufra under the caisson and the installation of an electric pump and water pipes.

Typical well structure and design

Well, at the final stage, you can show your imagination and equip a wooden canopy or put a log house with an elegant painted cover. There are no restrictions, because the well must not only function well, but also have an aesthetic appearance.