The vapor barrier of the floor is primarily necessary in rooms above basements and located on 1 floors of residential or industrial buildings without basement floors. Typically, this technology is used if mineral wool is used to insulate the floor. With increased humidity, this material dampens and loses the properties of the insulation. Also, vapor barrier is widely used when installing floors in saunas and baths to minimize steam loss to a minimum..

Content

- Materials for vapor barrier floor

- Compare, evaluate, choose

- The most ordinary plastic film

- Modern polyethylene vapor barrier

- Membrane vapor barrier – the leader

Materials for vapor barrier floor

What materials can be classified as modern? Of course, film – the most common and widely used today. Until the early 90’s. information about them in our country was practically absent. Mainly used roofing materials, glassine, roofing felt or ordinary plastic film (sleeve). And often they were not used at all. The appearance on the Russian market of a wide range of vapor barrier films is associated with the development of elite buildings, which required high-quality materials. It should be noted that these films are divided into vapor barrier (protecting it from water vapor) very conditionally. Since many of them can be successfully classified as waterproofing (protecting against water) and vice versa.

The following are popular:

- wind, – steam, – waterproofing “BRANE” (Russian production);

- wind, – steam, – waterproofing “DOMIZOL” (Russian production);

- wind, – steam, – waterproofing “Izospan” (Russian production);

- steam – waterproofing “TYVEK” (Danish production);

- ordinary polyethylene film.

Range of vapor barrier. Izospan includes a wide range of materials for equipping various structural elements.

Of all these materials, the most popular is the vapor barrier of the Isospan floor. For floors, the universal Isospan B, a two-layer membrane film made of polyethylene, is most often used. One of its sides is rough, designed to hold capillary fumes, and the second is smooth, facing the floor. Always mounted on the inside of the material – heat insulator.

It protects the insulated structures from vapors, prevents the formation of condensate, protects the building elements from damage by fungi and corrosion, and serves as protection against insulation fibers entering the premises. This film can be used in any buildings and with any type of insulation. Usually stacked on ceiling lags. Then, between the upper layer of the vapor-insulating material and the insulation, as well as between the vapor barrier and the final floor, a ventilation gap of 4-5 cm is arranged.

Compare, evaluate, choose

Now there are 4 main types of material used for vapor barrier work (used both inside and outside the building):

The most ordinary plastic film

It has several disadvantages. The main thing is that this material provokes the effect of a greenhouse in a room. However, his adherents often attribute this effect to pluses. They argue that in winter, thanks to the film, heating costs are reduced, and in summer this is not a problem, as everyone uses air conditioners.

The film has one more minus. When laying it, be sure to leave a small gap necessary for the evaporation of condensate. But due to the smoothness of the material on both sides, the condensate is not able to hold, so it flows down. There, it is partially absorbed into the thermal insulation layer. In this situation, the latter may eventually lose all its thermal insulation properties..

The usual vapor barrier film is rarely used now, it is being replaced by new, more effective and easier to install materials.

Modern polyethylene vapor barrier

Only one side is smooth, and the other is covered with small fibers. These roughnesses trap condensate that collects on the vertical surface of the vapor barrier layer. Accordingly, this avoids absorbing it into the thermal insulation. The main disadvantage of such a vapor barrier material is that it does not allow the surface to breathe.

Membrane vapor barrier – the leader

This is the 3rd type of material, which is usually used when working in residential premises or for domestic purposes. Today it is the best of their types of vapor barrier materials. It contributes to the preservation of the natural microclimate in the room. Vapors of hot air when using it are not able to reach the insulating layer. Unfortunately, its cost is quite high, so this high-tech membrane is not available to everyone.

Sometimes films coated with a foil reflecting infrared radiation are used. They are able to retain heat in the room, which is especially valuable..

Vapor barrier flooring

Vapor barrier of such a floor begins with the dismantling of previous coatings, preparation of the base or its repair if necessary. When all these works are completed – you can proceed directly to the installation of waterproofing.

So the steps are:

1. Removing old coatings, dismantling. It is necessary to eliminate all layers to the screed / cladding board. The screed must be carefully cleaned using a broom or vacuum cleaner. Then it should be inspected for defects (potholes, small and through cracks, large irregularities). If these are found in large numbers, some repairs will be required. It will be necessary to straighten the screed to prevent direct ingress of moisture that can penetrate through the through cracks from the ground.

2. Waterproofing installation. This is necessary as additional protection against moisture. If the waterproofing material is rolled, then it is overlapped, the joints are glued with ordinary adhesive tape or special tape.

3. Setting the lag in the design position. It is necessary to verify the level of each log so that the horizontalness is ideal. In this case, all wooden elements should be treated with an antiseptic. It will protect the wood from the appearance of fungi and mold, damage to its surface by insects..

4. Insulation Installation. It fits into the space located between the lags. If the insulation material is tiled, it is necessary to eliminate the existing gaps between it and the lags, so as not to create cold bridges.

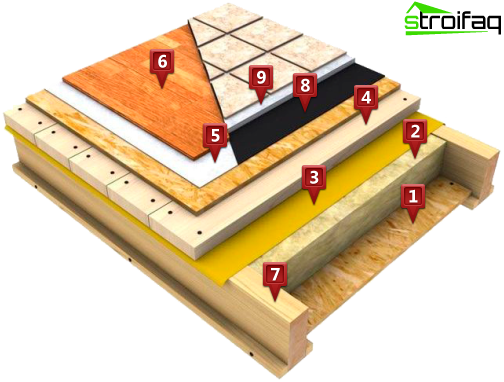

Stages of vapor barrier floor (all possible)

five. Laying vapor barrier on the floor. If a two-layer polypropylene film is used during installation (the second layer is an anti-condensation surface), then it is mounted to the insulation with the smooth side and rough inside the room. If the film is metallized, then it is placed to the insulation with the metallized side. A vapor insulator – polypropylene, which has a one-sided laminated coating of a propylene film, is placed on the heater with a smooth surface, woven side out. If a three-layer film with a reinforced mesh is used, which is laminated on two sides with a plastic film, then it should fit snugly against the heat insulator and have mandatory ventilation gaps of 2-5 cm.

6. Laying floorboards. When installing, keep in mind that a gap of 1-2 cm is desirable from the surface of the vapor barrier to the floor. If all technological work is done correctly, significant heat loss can be avoided, the thermal insulation performance in this situation will be at a height. This will ensure a constant comfortable room temperature even in extreme cold..

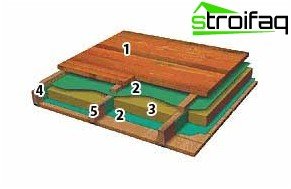

The most popular stages of the technology of insulation and vapor barrier of the floor

In general, the vapor barrier of the floor in a wooden house is not much different from similar technologies in other rooms. The technique can be applied on logs, on the ground, on wooden or reinforced concrete floors. The sequence of application of materials will be the same almost everywhere, allowing only minor variations.

For example, by lags:

- The first layer is planking

- Insulation

- Lags

- Vapor barrier

- Boardwalk

Vapor barrier on reinforced concrete slabs or arches

This issue should be considered separately. If you want to install vapor barrier on reinforced concrete slabs or arches, then you will need slightly different materials, for example, rolled ones – based on bitumen and similar mastics. Also suitable is polyethylene based on bitumen-polymer mastic. Sometimes they use ordinary bitumen-polymer mastic and cover it with the surface several times, thus obtaining a continuous, uniform layer.

The sequence of actions is as follows:

- Cleaning the ceiling from the previous coating, if any (for example, whitewash, painting, etc.)

- Survey of a surface, simultaneous elimination of all defects in the form of dents and cracks.

- Dust cleaning

- Application of mastics

- Laying roll materials. They should be spread out and secured in an overlap..

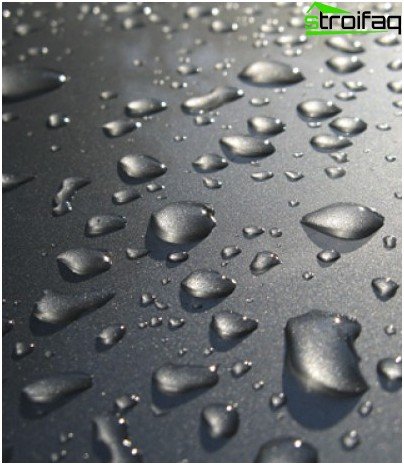

Wood floor and liquid rubber

There is another way to vapor barrier the floor, which will cover 100% of its surface, glue the vapor barrier to the base with good adhesion. To do this, you can use liquid rubber – a modern polymer-bitumen material. This is a highly elastic, seamless, environmentally friendly coating, effectively applied as a hydro, steam and sound insulation of a wooden floor.

Vapor barrier liquid rubber (film)

Liquid rubbers are:

- Applied in an automated manner. Used for vapor barrier of large surface areas – hundreds, thousands of m2. Usually in production.

- Manually applied to floors of several tens of m2.

It is done like this:

- a bucket of mastic is opened;

- the contents are mixed;

- with a roller or brush (with a spatula) the material is applied to the base.

Drying, this bitumen-polymer material forms a rubber film. She firmly glues to the floor and completely repeats its relief. It doesn’t pass any moisture: both from below in the form of steam, and from above in the form of water. The consumption of liquid rubber for vapor barrier of a wooden floor will be 1 kg (or 1.5 kg) per m2. The film thickness will be approximately 0.70 mm. One bucket (10kg) is enough to get 10m2 of a seamless vapor barrier for both concrete and wood with excellent adhesion. For the purpose of waterproofing, its consumption should be increased to 3-4 kg / m2.

We also note that the color of such a rubber vapor barrier is black, which does not matter if it is closed and invisible. Therefore, it should always be covered with a finishing floor..

To summarize all of the above, noting that waterproofing floors is not an extremely complicated and costly procedure. Sometimes it is completely optional. But in the classic technology of floor insulation, it is usually used, especially when it comes to rooms exposed to high humidity. Special materials help maintain heat in homes and significantly extend the life of floors..