Is it worth laying the substrate under linoleum

The question of whether a substrate for a laminate is necessary suggests an unambiguous and affirmative answer. The relevant question regarding linoleum causes a lot of controversy. Some believe that the linoleum substrate is completely useless, while others are sure of its necessity. Of course, everyone decides whether he needs a substrate, but to make a decision it is recommended to get acquainted with the basic functions of the substrate, its advantages and disadvantages.

Content

- Basic substrate features

- Linoleum substrate: choose

- Why is cork better?

Basic substrate features

It is customary to distinguish two main functions of the substrate:

- masking surface irregularities;

- floor insulation.

During repair work, any unevenness may remain on the floor surface. Despite its mandatory alignment in front of the flooring, no one is immune from minor defects. However, household linoleum is soft, and all the irregularities will be clearly visible over time, in addition, there is a risk of its rupture in these places. Laying the linoleum substrate allows you to hide these defects and significantly increase the life of the coating.

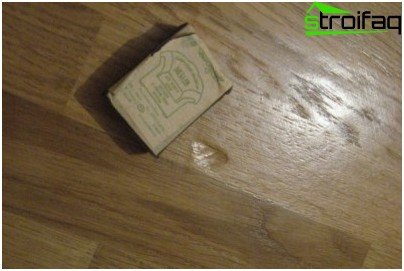

Linoleum defect – gap

The second main function of the substrate is floor insulation. Obviously, linoleum laid directly on a cement-sand screed will be quite cold, and walking on such a floor is not too comfortable. This is especially true for the first floor of a multi-storey building and private houses in which there is a basement.

However, it is not enough just to solve the question of the need to lay the substrate under linoleum. Still to make the right choice of material.

Linoleum substrate: choose

Experts categorically do not recommend laying a foamed substrate under linoleum, since this entails rather sad consequences. The linoleum itself does not lie smoothly on the foam and during operation, dents will immediately appear on it, which over time can lead to tearing of the floor covering.

Manufacturers of linoleum also advise to abandon this option of floor insulation. It is easy to demonstrate its unsuitability. You can take a sheet of plain paper and put it on a hard surface, such as a table. Then push the tip of the knife onto the paper. Life experience and a good example will tell you that nothing will happen to the paper, maximum – a very small hole will appear on it.

However, if you put something relatively soft under the paper, even if you put a piece of substrate under the linoleum and press the sheet with the same tip of the knife, a hole will immediately form in it.

Of course, linoleum is difficult to equate to paper by the degree of fragility, but the analogy is obvious: linoleum will be easily susceptible to tearing and mechanical stress. At the same time, walking on such linoleum will be extremely warm and comfortable. But buying a not-so-heavy computer chair can turn a square meter of flooring into a mess.

Dent on linoleum

So, today experts single out several options for the most suitable linoleum substrates. These include:

- jute fiber;

- natural linen backing;

- a mixture of linen, jute and wool;

- Fiberboard or plywood;

- cork material of maximum rigidity.

Of course, each type of substrate has certain advantages and disadvantages, so you need to make a choice based on the operating conditions of the flooring, your own preferences and financial capabilities.

So, jute material is ideal for improving the thermal insulation properties of linoleum. This is especially true in cases where the concrete screed was laid directly on the ground or under the house there is a basement that is not heated. The jute substrate is environmentally friendly, safe and able to maintain a favorable microclimate in the room. However, when choosing a jute substrate, pay attention to its density – it should be maximum.

In general, the stiffness requirement is common to all types of substrates. The fact is that in the presence of a soft substrate, on which there is also a soft household linoleum, the likelihood that ugly dents will remain on the floor is too high. Moreover, such a floor will spring somewhat, which does not at all create comfort when walking. It would seem that in this case, the ideal option would be plywood or fiberboard. However, this opinion is erroneous..

Experienced builders consider plywood unsuitable for the substrate, as it reduces the life of linoleum. Plywood is more suitable as a substrate for a wooden floor. As for fiberboard, its use is also controversial. This is due to the fact that this material does not have good moisture resistance and resistance to temperature extremes. Of course, this leads to deformation of the substrate and, as a consequence, to deformation of the floor covering.

Many experts agree that cork is the best option..

Why is cork better?

As a rule, cork substrate is sold in the form of rolls, which creates a certain convenience when laying. When purchasing material, you must accurately find out from the seller the degree of its rigidity.

The popularity of cork material is due to its operational qualities, which are ensured by its structure. The cork has a cellular structure: in each cell, as if a bubble of air were sealed. This allows you to efficiently distribute the load on the floor covering..

Cork linoleum underlay

So, the cork substrate under linoleum is characterized by the following operational properties:

- high-quality soundproofing;

- retains heat, which allows you to walk barefoot on the floor even in severe frosts;

- moisture resistant;

- does not contribute to the growth of mold and other harmful microorganisms;

- protects flooring from damage.

Thus, the answer to the question of whether a linoleum substrate is needed is likely to be in the affirmative. It performs two, but very important functions: it masks the unevenness of the floor and insulates the floor. However, it is worth considering that you will have to choose one or another material for it yourself, taking into account some nuances: your capabilities, preferences and operating conditions of the floor covering and substrate.