Film infrared heat-insulated floor

More recently, only cable or water floor heating was used for heating. However, in developed countries, a new revolutionary technology was already widely used, of which only a few knew about Russia – the film floor. Time passed, and today the infrared warm floor is very popular. The system is available to create comfortable warm areas in private homes, office premises and apartments..

Content

- Film floor construction

- The principle of operation of a radiant infrared heater

- The benefits of infrared film

- Use of film heating systems

- Floor compatibility

- Infrared underfloor heating device

- Preparing for the installation of a film system

- The process of laying infrared film

- Connection of temperature sensor and heat regulator

Film floor construction

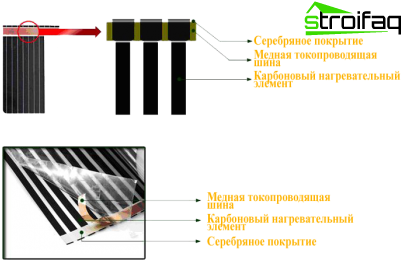

What is an infrared warm floor – consumer reviews will help to understand this issue. This is a heating system that is based on a heating film. A radiant infrared heater is structurally composed of such parts. The heating element is made in the form of conductive strips with a pitch of 15 millimeters, which are made using Carbon NanoTube technology.

Infrared film floor construction

Electricity is supplied through copper-silver conductors. On both sides, the entire system is hermetically laminated with a polymer that is resistant to environmental factors, and also has enhanced fire, waterproof and electrical insulation properties. Connection to the network is carried out in parallel through the thermostat.

The high quality of materials, the density of the joint, fireproof polyethylene coating, as well as the use of adsorbent carbon deposition guarantee a high level of safety and continuous operation of heaters. With mechanical damage, only the damaged area will fail, and the entire system will continue to function..

It is advisable to install an infrared heat-insulated floor in your home – technical specifications are proof of this. The design features of the system contribute to a uniform distribution of heating over the surface and stability of the temperature in the room.

The principle of operation of a radiant infrared heater

The infrared floor heating system is powered by the mains. In houses with normal thermal insulation, the average daily electricity consumption is close to 25 – 50 W per 1 square meter per hour.

The control of the electric temperature regulator allows minimizing the cost of electricity for heating by means of operational temperature control in all rooms. Along with this, maximum comfort is achieved for people in housing.

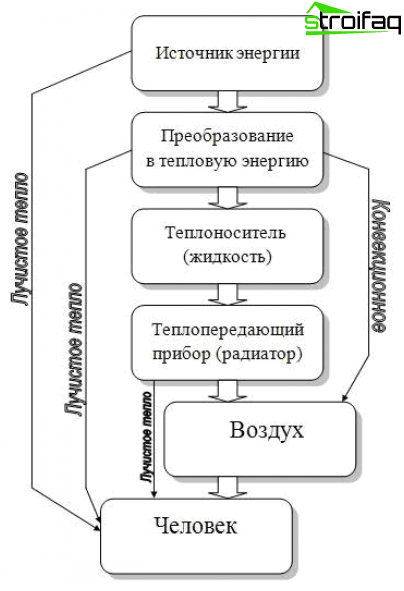

The principle of operation of the infrared heater

Design features, installation of a warm film floor and the principle of its operation excludes the presence of an electromagnetic field in the room, which is present in any cable-type system. When connected, the film emits long infrared rays and anions – negatively charged ions.

The heat created by the infrared heater favorably affects human health, and it feels compared to sunlight. To direct the heat flux not to heat the ceiling of neighbors from below, but to heat the floor in your home, it is customary to use a heat-reflecting substrate. The energy released by infrared floors warms not ambient air, but objects.

The benefits of infrared film

The infrared heater quickly responds to changes in the external environment, so the room warms up faster. Installing a film underfloor heating means turning off the heating when the room has become warmer.

The advantages of the underfloor heating system: a comparison scheme with the operation of central heating

It is necessary to list the main advantages of such a film:

- uniform heating of the room;

- energy saving;

- an increase in the efficiency of using an energy carrier compared to a convective type of heating;

- excluded cooling and overheating of the room, as well as freezing of the system itself;

- reduction of dustiness of the room;

- complete independence from the central heating schedule;

- stealth in the interior;

- maintenance costs are excluded;

- there is no feeling of stuffiness;

- maintaining natural moisture;

- silent work;

- easy assembly and disassembly.

Use of film heating systems

Underfloor heating systems are used by installing under ceiling and floor coverings, and are also used in wall panels and any curved surfaces without fear of deformation. However, the film heat-insulated floor nanothermal is not intended for installation in the open air without any protection.

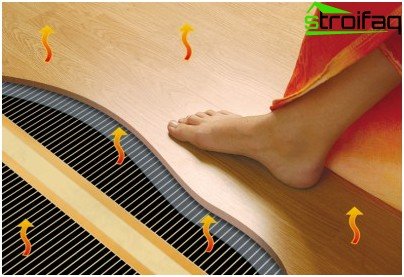

The use of underfloor heating in housing: the most necessary zone is heated to create a comfortable temperature

The underfloor heating system is used for heating rooms for various purposes. If necessary, infrared film can be used as a temporary or additional heating option. In addition, it is rational to use infrared floors in buildings in which there is simply no stationary heating. It is advisable to install a warm floor as an emergency source of heating.

Infrared film floor heating is suitable for heating hospitals, schools, kindergartens, hotels and other public buildings. Similar systems can be used in agriculture, industrial premises and in general, anywhere.

In addition, homeowners and entrepreneurs themselves are looking for new ways to use the film – for example, for heating all kinds of equipment and heating tanks. But the most popular infrared heater for heating apartments, private and country houses.

Floor compatibility

The infrared heater is compatible with all types of flooring. The film heating system is suitable for installation under light coatings – laminate and parquet boards, carpet and linoleum. The connection of film heaters in this case does not require special professional skills and does not imply complicated technological solutions.

Infrared flooring compatible with any type of flooring

At the same time, if a person has sufficient experience in carrying out construction and installation works, a film heat-insulated floor can be installed safely under any types of stone, composite and ceramic materials. Reliability and economic efficiency of this heating exceeds in many respects the traditional systems of water and cable floor heating existing on the market.

The film thickness is only 0.4 millimeters, and this in turn allows you to install the heater directly under the floors, without fear for coverage. The infrared system is characterized by a low heating temperature, but at the same time maximum heat transfer is achieved.

The underfloor heating system, which is made on the basis of a resistive film, does not heat up above 45 degrees Celsius. This has a beneficial effect on the human body and on the floor covering. In addition, any interior design can be implemented without giving up comfortable warm floors.

Infrared underfloor heating device

Infrared film can be installed independently. Installation of an infrared warm floor is not so complicated, you should only study the instructions in detail and calculate the required amount of material. The system can be stacked not over the entire area, but up to 70-80% of the required heating space, without reducing the quality of the heating.

Preparing for the installation of a film system

If you plan to cover the carpet or linoleum, then any type of insulation is suitable, the thickness of the sheet should only reach 3 – 5 millimeters. If ceramic tiles are to be laid on the floor, it is advisable to use thermal insulation from a technical cork, the thickness of which is 2 millimeters.

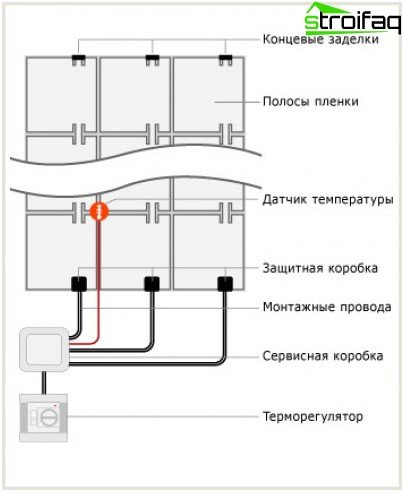

Preparation for the installation of a film floor includes an obligatory stage – the development of a scheme

When installing a warm film floor, it is worthwhile to determine the location of the thermostat in advance and make an installation diagram to lay out the infrared film correctly on the floor. The material should be laid in open areas of the floor where furniture will not be located.

The process of laying infrared film

How to install a film underfloor heating with your own hands? Heat-insulating material is laid on the prepared cleaned floor surface. The film should be cut into strips of the required size along special marked lines on it. After that, the film must be laid out on the floor according to the compiled installation diagram with the contacts to the wall where the temperature regulator will be installed, and with a copper strip.

Wiring diagram without crossing wires

Then it’s worth connecting the film to the wiring by installing the contact clamps on the edges of the copper strip and connecting the contact wires to them. It is recommended to isolate all places where the wire is connected to the clamps and the cut points of the infrared film with bitumen insulation.

Standard infrared film setting

Connection of temperature sensor and heat regulator

The floor temperature sensor is connected from the bottom of the film and is also necessarily insulated. When the installation of the film warm floor is finished, all the wires and contacts are connected, you need to install a heat regulator, isolate the contacts and connect the device to the mains.

Connecting a thermostat – final work

For additional protection, a plastic film needs to be laid on top of the warm floor. The film flooring system has many hidden contacts, unlike the cable floor, so be sure to test the new infrared floor. The surface should be evenly heated without sparks and heating of the junction of the contacts.

And only after that you can start laying the finish flooring. If you need to lay ceramic tiles, then after work you should let the screed under it dry for 20 days, then you can use the floor heating system.

Thus, the infrared warm floor is not in vain called a revolutionary technology in the market of heating systems. Installation of the film can be done in rooms of different directions, as the material has a number of advantages. On the other hand, installation work can be performed even by a person who does not have professional construction skills. All this explains the huge popularity of the product..