Which substrate is better

Laminate flooring is a popular floor covering that attracts with such advantages as durability, reliability, ease of installation, low cost and beautiful appearance. However, when laying, it is worth worrying about the presence of an insulating layer that smoothes out irregularities, has shock-absorbing, sound and heat-insulating properties. Moreover, the substrate under the laminate is the component with which the installation process of a beautiful and high-quality floor.

Content

- Task and Substrate Functions

- The choice of substrate for the laminate

- Polyethylene foam backing

- Composite materials and cork

- Isolon (foil backing)

- Fiberglass backing properties

Task and Substrate Functions

Many, trying to save money, believe that when laying a laminate, you can do without a substrate. But this is an erroneous opinion, which is unlikely to help out on building materials, rather, on the contrary, subsequently it will be necessary to spend a considerable amount dismantling the recently laid floor. So, what is the main purpose of the substrate, why is it needed?

The substrate performs a lot of functions: isolation, lack of squeak, extension of the operating life

- Sound and sound insulation. The substrate for the laminate muffles the sounds of steps, noise from neighboring rooms and other obstacles that can interfere with work or rest;

- Thermal insulation. Of course, the substrate is unlikely to fully replace the “warm floor”, but children can play on the floor in winter with ease;

- The lack of squeaks. The creaking of floorboards is a fairly common occurrence that can now be avoided;

- Extend the life of the laminate. Properly laid substrate can significantly increase the service life of the floor covering. There are samples with special moisture-resistant membranes that provide maximum stability and reliability of the floor;

- Elimination of differences, roughnesses and defects of a floor.

The choice of substrate for the laminate

The market of modern building materials offers a huge number of options that differ in the method of manufacture, quality characteristics, thickness.

In light of this situation, the substrate under the laminate: which is better – a problem that worries many. In order to find the answer to such an urgent question, you need to have at least a minimum of information on the topic.

Polyethylene foam backing

The most common, simple and affordable type. The material is resistant to solvents, oils, is not afraid of moisture, bacteria and mold. Polyethylene foam is easily processed with standard tools and is easy to assemble. Butt laying is done, the areas of which are glued with construction tape.

Polyethylene foam substrate is the most common option, minus it in the loss of elasticity during intensive use

It is important! When using polyethylene foam, the thickness of the substrate under the laminate is 2 mm.

The foam backing is an excellent sound and vapor insulator, with only one minus – loss of elasticity during use, as a result of which gaps appear under the laminate, making a dull sound when walking.

Polyethylene substrates are:

- from physically cross-linked, foamed polyethylene. It is characterized by increased sound insulation, ideal for insulation;

- from gas-filled polyethylene having a non-crosslinked structure and manufactured by extrusion (foaming with gas);

- made of chemically cross-linked polyethylene, which is not very expensive but has good characteristics.

Composite materials and cork

Such substrates are made from pressed cork crumbs (serves as a base) and various additives. Allocate materials:

- TUPLEX is a composite substrate from Finland, having a thickness of 3 mm. The design consists of polystyrene granules laid between a polymer film. Moreover, the lower layer is vapor-permeable, i.e. moisture from the base freely enters the thickness of the substrate. The top layer is presented in the form of a vapor barrier film that helps to remove moisture through ventilated baseboards.

The TUPLEX backing is equipped with a vapor barrier – a great bonus for laying laminate on top of a wooden subfloor

It is important! When using the TUPLEX substrate, condensation under the laminate does not form, which means that neither fungus nor mold threatens you.

Such a composite substrate is laid without adhesive tape – each roll is equipped with an adhesive overlap that allows you to connect sheets into one system.

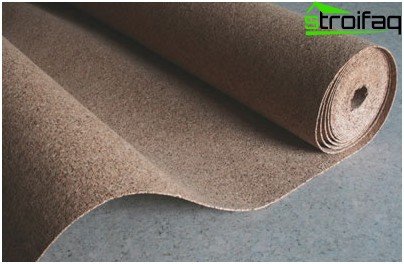

- The best material for laying under the laminate is cork substrate, which is made from cork crushed pressed and glued into sheets with a thickness of 2 mm. As a glue acts a natural component – suberin. The main advantages of this natural raw material are environmental friendliness, high heat and sound insulation properties, resistance to decay processes. In addition, cork does not lose its original qualities over time..

Cork backing is the best material made using natural ingredients.

Cork substrates are divided into:

- Bitumen-cork – a cellulose base impregnated with bitumen on one side. Cork chips are added to cellulose; the thickness of such protection is 2-5 mm. The bottom layer (cork) forms a ventilated cavity that prevents condensation. Bitumen acts as a waterproofing agent, which makes such a layer especially necessary in conditions of high humidity.

- Rubber-cork – consisting of technical cork crumb, rubber granulate and a binder polymer. They have the best sound insulation, protect against vibration and absorb shock waves. The thickness is selected depending on the noise level that you want to drown.

Isolon (foil backing)

A sufficiently demanded material for insulation, which is a foamed polymer coated with a metal foil. When arranging comfortable floors, the isolon is indispensable, the foil, like a mirror, reflects the heat of the floor inside the room. Among the shortcomings, one can mention the high cost: for a foil substrate, you will have to pay three times more than for the above types.

A foil substrate is recommended when installing a laminate floor above an infrared heating system, if the brand of the laminate is compatible with this floor construction scheme

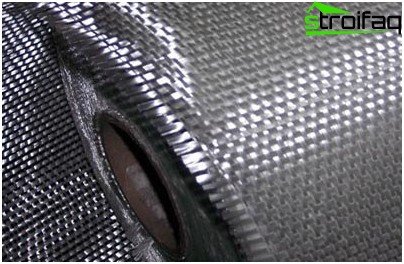

Fiberglass backing properties

They are made on the basis of slab soundproofing and are most often used for a laminate of 5-7 mm thick, as well as when mounting on a concrete or wooden base. Pros:

- Environmental friendliness. In the manufacturing process, glue and other chemicals are not used;

- Mechanical strength: plates do not shrink, do not deform (even with moisture);

- Possibility of laying on a bare base of concrete or wood;

High soundproof qualities, elasticity.

Fiberglass backing can be laid on any base.

What you need to know when choosing?

When choosing, you should be guided by the properties of the materials. Please note that artificial raw materials are stable, do not shrink, and are not subject to external influences. Polyethylene substrates are good for leveling the surface, they perfectly absorb noise and make your floor very warm.

Cork substrates are mounted under a luxury laminate, have zero absorption and remarkably hide noise.

The underlay will make your floor warm and beautiful.

Bituminous materials are laid if good ventilation and protection against liquids are important.

It is important! When choosing a substrate, it is necessary to take into account the thickness and class (economy, medium, first).

Now that all the necessary theoretical foundations have been obtained, choosing a substrate for a laminate is not difficult. So, the floor in your house will be of high quality, reliable, warm and beautiful..