Choose a substrate for the parquet board

A substrate for a parquet board is a necessary accompanying material when laying parquet. It helps to partially smooth out unevenness of the base, helps to muffle the sounds of steps on the floor, prevents the penetration of moisture and its destructive effects on the parquet, as well as the leakage of such valuable heat from the room. There are a lot of types of substrates: cork, made of foamed propylene, Duplex and others. It is important to choose from them the best one that most fully meets the needs of the consumer for its functional and quality properties. Let’s consider all types in stages.

Content

- Types of underlay for parquet

- Foam propylene backing

- Cork – the leader in the range

- Three-layer substrate Duplex

- Parklog: cons and pros

- The substrate containing the foil layer

Types of underlay for parquet

Foam propylene backing

Foam propylene backing

This is the cheapest substrate. Its main advantage is its excellent vapor barrier, it also meets all the requirements for installation, perfectly dampens vibrations from walking on the floor, increases its heat and sound insulation. However, it is short-lived – the complete disintegration of the material occurs after 7-10 years (do not forget to subtract from this period the time spent by the rolls in the warehouse).

After the expiration date, it turns into a powder and loses all the positive properties. The second fundamental drawback is the fire hazard of foamed polymers. They ignite even easier than wood. At the same time, it is necessary to take into account the high toxicity during combustion, because of which many do not risk purchasing this material.

Cork – the leader in the range

Cork backing

This type of substrate is traditionally used for parquet. Cork is the best natural heat and noise insulator, has good shock-absorbing properties, is naturally strong and flexible, durable, completely natural product (does not contain aromatic hydrocarbons and formaldehyde), it can rightfully be attributed to excellent, high-quality materials. Often used when installing parquet in the nursery, when laying underfloor heating.

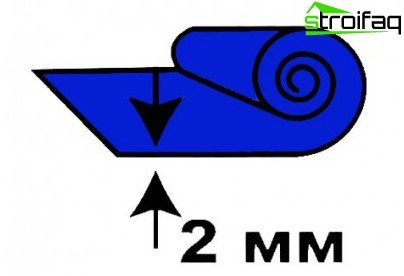

Such a substrate is produced in different thicknesses (from 1.5 to 10), only 2 mm thick material should be used for parquet. When using thinner material – it will crumble, significantly reducing the life of the floors. When using a cork thicker, an excessive load on the lock parquet connection will occur. It is worth noting that the cork substrate for the parquet board has one serious minus – the cork swells from water. It can be eliminated if you purchase such a substrate with a plastic layer or apply it yourself as a waterproofing.

Three-layer substrate Duplex

Substrate Duplex

This is a material consisting of 3 layers. The bottom layer is a porous film that passes moisture into the middle layer, which is packed with balls designed to maintain its constant height (there is a ventilated air layer between the balls). The top layer is a plastic film.

Such a substrate will be especially effective in case of insufficiently dried screed, as well as in the presence of condensate on it due to irregular heating of the room. Moisture will penetrate through the pores into the middle layer, and then it is well weathered through the air ducts around the entire perimeter of the room in those places where the gaps between the wall and the parquet board are located. Thus, the risk of damage to the floorboard is significantly reduced. Perhaps Duplex is the best underlay for parquet board today. It can only compete with cork, especially since their prices are approximately the same.

Parklog: cons and pros

Substrate Parkolag

This material is based on bitumen mastic, is a new and actively promoted product on the Russian market. However, along with such indisputable advantages of the Parkolag as excellent heat and noise insulation and moisture resistance, durability, there is a serious drawback: bitumen mastic emits formaldehyde in large quantities, especially in hot weather or when located near heat-conducting pipes. That is why materials containing bitumen are prohibited in many institutions and countries in the world..

The substrate containing the foil layer

Such a layer is a useful addition that improves the properties of the substrate material. They provide good heat, hydro and sound insulation of parquet. Most often, foamed polymer material is folded, but also its other varieties. It is advisable to use it when laying parquet on the logs with rigid fixation of the board.

The thickness of the substrate under the parquet board

The thickness of the substrate for the parquet should be equal to 2 mm

This question is of interest to many, because such a characteristic has a fundamental impact on the performance properties of both the substrate and the parquet itself. Therefore, we will highlight it in detail.

This material should not be too thick or too thin. According to the standard, when laying parquet, the maximum height difference can be 3 mm per 2 m ?. These figures are calculated taking into account the shrinkage of the substrate and the difference in the base itself. The standard and optimal thickness of the parquet substrate is 2 mm, which allows it to fit into the allowable difference. Soft materials, such as cork or foam backing, are compressed by pressure. If their layer is large, this will provoke large differences in height. And this, in turn, will create a backlash on the lock joints of the parquet board, which will cause increased wear of the lock connection, the appearance of a creak. It is noteworthy that the parquet board begins to creak, and the lock – to break off – is not immediately. A stacking fault can only be detected after a few months.

When additional moisture insulation is needed?

Almost all types of substrates (except Parkolag and Duplex) have a porous structure that is not protected from moisture. When laying on leveling dry sheets or plywood, additional moisture insulation is not needed. If the installation of the parquet board occurs on the screed, then it is recommended to lay a plastic film under the moisture-proof substrate. After all, the properties of the screed are known: on its surface, due to the difference in temperature over time, dew appears.

We examined all the most popular types of substrates for parquet, describing their basic properties. Which one to prefer is for you to decide, however, the cork substrate and Tuplex remain confidently the leaders in the market in terms of quality and operational properties. If finances allow, it is better to purchase them.