How to choose a parquet board

A practical democratic parquet board was invented and put into production in the 40s of the last century. It appeared as a worthy alternative to an expensive piece parquet floor. Popular flooring is now produced by hundreds of companies constantly improving their product. Many collections are delivered to the market each year with amazing design and enhanced features. An extensive assortment of modernized products can puzzle even a sophisticated buyer. Recommendations and information on what properties to pay attention to and how to choose a parquet board will help determine the future acquisition of experienced and inexperienced future owners.

Content

- Choice: Operating Environment

- Examine the documents attached to the product

- Floor element size

- Single or Three Strip?

- Characterization of single-lane material

- Two-way parquet board

- Parquet three-strip

- New Word – Multiband

Attractive sides of a parquet board convince better than any advertisement in the rationality of arranging commercial, administrative and residential premises with the help of this material.

- The installation of the floor using a parquet board takes a significantly shorter period of time than is required for the scrupulous combination of piece parquet dies.

- Cheaper installation.

- Significantly lower than the price of a floor fully prepared for work.

- You do not need to cycle the parquet board, carefully grind and apply several layers of protective and decorative varnish.

- Due to the special design, this floor covering does not react as sharply as a parquet floor to moisture level fluctuations, temperature changes.

Oak parquet board – democratic presentable practical material

The service life guaranteed by manufacturers of parquet boards is lower than that of presentable parquet, but replacement in the event of a global alteration of the interior will not be painful for the family budget.

Choice: Operating Environment

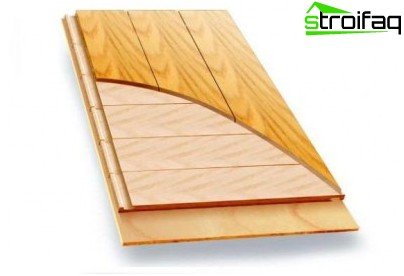

The technical priorities of the parquet board are determined by the structural specifics of the flooring elements. Their structure resembles a sandwich made up of three or more layers of wood of different values. The fibers of the upper facial veneer, made of expensive wood, are perpendicular to the fibers of the underlying layer. The structural components of the lower layer are again attached “to the cross” to the previous.

Thanks to the alternating directions of the lamellas, the layered system perfectly tolerates all the hardships of domestic influences. However, it can still deteriorate from excess moisture. Therefore, the laying of a parquet board in rooms with unfavorable conditions for wood, most manufacturers do not recommend, as described in the instructions attached to the product.

The absence of deformation changes is justified by the design features of the floorboard

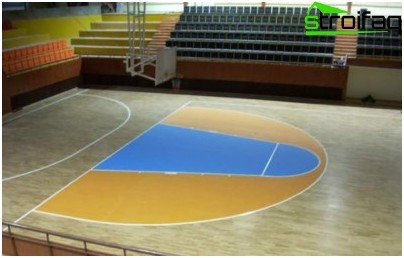

Parquet board, for the manufacture of which only wood is used, belongs to the category of products with high environmental criteria. It is suitable for arranging nurseries and bedrooms, it is used for decorating living rooms, home offices, respectable offices. There are options designed specifically for sports complexes and dance halls. Information on the operational specifics and the ability of the flooring to resist dynamic and static loads is indicated in the product labeling.

For laying floors in sports complexes there are specific brands of parquet boards

Examine the documents attached to the product

Everyone who wants to lay a parquet board should study the information provided by the manufacturer. Good products come with certificates and a complete package of technical documentation. A reliable company that is attentive to its customers, always indicates all the details that need to be taken into account by future users. In thoroughly drawn up recommendations, there is always information about:

- Is this modification compatible with the “warm floor” system?

- on what basis can the series offered for sale be put;

- Is it possible to use the parquet board in rooms not equipped with a climate system.

Potential buyers, puzzled by the question “which floorboard to choose”, should be interested in information about the maximum floor width. This characteristic displays the strength of the locking joint. A number of the latest brands from leading manufacturers can “boast” the possibility of arranging a floor with a width of 16-18 m. This means that you can choose the transverse or diagonal direction for laying the coating, without fear that end locks will deteriorate from the load of weighty furniture along opposite walls or gaps will appear in winter.

The maximum possible width for laying parquet board is a significant characteristic, which must be indicated by the responsible manufacturer

An important parameter is the permissible unevenness of the foundation intended for arrangement.

This indicator, as well as the previous characteristic, will necessarily be indicated by the responsible supplier, in contrast to dubious firms. The most durable grades are distinguished by a tolerance of 3 mm per two-meter length of flooring, basically a standard deviation of 2 mm per meter of board is allowed.

Information on the maximum allowable roughness is required for the proper selection of the adhesive composition. The need to use glue with enhanced strength properties can significantly increase the cost of laying the coating as a whole. The dilemma is again before the buyer: to buy expensive material and cheap glue, or to prefer a different combination?

In any case, saving on glue is not worth it, even if it is used only to strengthen the lock joints in the floating floor structure.

Floor element size

According to the regulations of European standards, a parquet board is produced with a length of elements of 2-2.5 meters, a width of up to 20 cm. There are much more options for thickness. The thickness of the thinnest material is 7 cm, the size of the thickest boards is 26 cm.

Important. Due to the insignificant thickness of the veneer of the thinnest parquet board options, such material cannot be cycled.

You can restore decorative qualities by looping slats equipped with a working layer with a capacity exceeding 4 mm. These are 13-15 mm stamps used for arranging public premises and housing.

For the installation of a wear-resistant durable floor in rooms with an intensive degree of patency, mainly flooring with a thickness of boards of 20 mm is used. The thickness of the veneer in contact with the soles of shoes and furniture in these specimens is equal to or greater than 6 mm. A parquet board with a capacity of 22 mm or more is recommended for laying floors subjected to intense dynamic load. It can be laid directly on the draft floor, on the logs.

Single or Three Strip?

One of the classification features of a parquet board is the number of rows of dies that make up the top layer of material. On the basis of which the floor covering is divided into various types, the characteristics of which are given below.

One-sided parquet board with a facet

Characterization of single-lane material

A single-lane board veneered with one whole plank. Its front layer is represented by a whole layer of expensive tree species. The material is distinguished by the charm of a natural structure, the beauty of a natural pattern, depending on the cutting technology. The method of sawing wood affects the shade of the face layer, the distinctness of natural lines and the presence of defects inherent in the tree. A single-lane parquet board is chosen in order to visually expand the geometric framework of the room.

Two-way parquet board

Its working layer is made up of two perfectly fitted lamellas. Components can be solid, continuous along the entire length of the board or divided into 2 or 3 segments. The two-way coating pattern is more diverse, and the type of selection also affects its specificity..

Parquet three-strip

The top layer of a three-lane is composed of three parallel rows of lamellas. The most popular material, having a classic look of a piece parquet floor. In the collections of a three-lane parquet board there are options with the arrangement of segments of the famous parquet herringbone, wicker, with the traditional longitudinal orientation of all components.

New Word – Multiband

Multiband is an innovative innovation of recent years, appreciated by designers and consumers. Its decorative layer is assembled manually from individual components of a small area. Veneer strips fit perfectly; butt joints are often difficult to identify visually. Finished products are striking in their sophistication of the range of shades and the beauty of the structure. They prefer to lay a multi-strip parquet board in rooms with an ascetic design. It in itself is a rich interior element that emphasizes attention. Its advantage lies in the invisibility of minor defects that may appear during operation.

Different options for single-lane, two-, three-lane parquet boards and multi-lane copies

Type of selection and decorative indicators

In the list of questions combined in one phrase “how to choose the right parquet board”, decorative criteria occupy not the least place. They directly depend on the method of cutting logs for veneer harvesting. Cutting technology affects the strength characteristics of the front layer, the presence / absence and number of defects. In the production of components for parquet boards use:

- The radial sawing method, performed in parallel with the shared shaft guide. As a result, the dies get an even pattern of longitudinally arranged fibers with a uniform shade and a maximum level of stability.

- The tangential type of cut, directed along the tangent to the structural rings of the trunk. Tangentially sawn timber distinguishes the originality of the pattern..

- Rustic cut, for which the angle is not regulated. Rustic cut veneer is characterized by heterogeneity of color and pattern..

According to the external indicators laid down by cutting and processing, the planks are selected for the formation of a single batch. Selection criteria, i.e. sorting, are the shade, pattern of the bar and the presence of defects on it. Mostly parquet board goes on sale, sorted according to the requirements of the following types of selection:

- Select is the most demanding type of sorting, involving the formation of a batch with perfectly even color, the highest technical indicators, with a beautiful uniform pattern. Such material is sawn radially.

- Natur is a type of selection that allows for uneven color transitions, differences in the natural pattern, and minor small-caliber defects in the consignment. In a batch of products sorted according to the requirements of selection of natures, material with a top layer made by radial and tangential sawing is selected.

- Rustic is a type of selection without restrictions in the type of cut, but predetermining sorting by quality indicators and color. Rustic parquet board pattern is the most colorful, even colorful, sapwood and knots are possible.

Rustic parquet flooring an impressive colorful interior element

Famous sales and production campaigns such as Tarkett use their sorting classification. Their collections contain stamps selected according to the criteria of Premium selection with high selection requirements, Robust, close to the Rustic variety, and other variations.

However, there are no significant deviations in the selection regulated by EN standards. The cost of material for flooring depends on the type of sorting. The more demanding the selection, the better the quality, but also the higher the price.

Wood as one of the landmarks

Future owners of furnished housing are interested in a lot of questions. What attracts one or another parquet board: which one will fit better into a given interior composition, which brand will ideally combine with existing furniture or with brand new finishes? A significant factor for the consumer is wear resistance. Abrasion resistance and density, interrelated with strength, are also significant parameters. All these indicators are determined by the wood chosen by the supplier of the products..

To produce the supporting layer of the parquet board, most manufacturing companies use northern conifers. They are distinguished by stability and strength over the entire floor area. Sometimes the lower layer is made of hevea, characterized by resin and moisture resistance. The rocks of the lower layer are not prone to deformation, protected from moisture due to the presence of natural components.

1. valuable wood veneer 2. middle layer made from budget varieties 3. lower layer made from coniferous northern species of wood F. varnish coating applied in five layers

To veneer the planks of the parquet board, both growing species in Europe and Asia and exotic wood from other continents are used. The most popular material is equipped with oak veneer. The beauty and strength of oak over time is not just preserved, but increased. Its wood strikes with an abundance of noble beige, yellow, cognac shades.

Soft yellow with sparkles ash wood is popular with those who want to visually enlarge the room. According to the strength characteristics, ash is not much inferior to oak. Designers recommend solar beech paints for arranging nurseries. In addition, beech is not as durable as stone-like wood of a mighty oak, therefore it is used to equip rooms with low loads..

Many people like the creamy color of maple, which is also a fairly durable material. Adherents of interior delights often prefer pink cherry color, saturated with coffee and delicate cream nuances. A solid brown floor with golden stains will turn out when laying a merbau board growing in Indonesia. For a device of almost black sex, a board with veneer from the African wenge breed is used. The floor covering with a front layer of kempas will paint the lower plane of the room in amazing brick orange tones..

Parquet board wenge – exclusive African flavor

Varnish or oil impregnation?

Manufacturers apply oil or multilayer varnish to the material during the manufacturing process. This fact is one of the priorities of the parquet board, which does not need processing after installation. Most often, the varnish is applied in five layers, its hardening is carried out under the influence of UV radiation. By hardening the surface in this way, manufacturers increase the stability of wood and resistance to external influences. The varnish-treated floor is easy to clean; moisture does not enter the closed pores of natural organics..

Multicomponent oil impregnation – a new solution in the processing of parquet boards

Multicomponent parquet oil, which contains resins, wax and vegetable fats, impregnates the material without closing its natural pores. The floor treated with oil “breathes”, but the oily components do not allow moisture into the wood texture. Although rare light wet cleaning is allowed, an oiled parquet board will require a more careful and attentive attitude. An argument in favor of oil-treated planks is the recognition of a non-embossing restoration of worn and scratched areas.

Having studied the properties and characteristics, it is easy to make a choice in favor of priority flooring that meets individual requirements. Knowing the main guidelines, it is easier to make a quality assessment of the goods from the point of view of the future owner and taking into account individual requirements.