The wooden floor is environmentally friendly, warm and has a beautiful appearance. After all, wood is a natural material with a lot of useful qualities: low heat conductivity, good sound insulation, beautiful texture. The wooden floor is convenient in processing, there is always the possibility of restoration if necessary. But in order for the wooden floor to serve for a long time, it is necessary to provide appropriate operating conditions. Proper waterproofing of the wooden floor is the main condition for its durability.

Content

- Classification of floor waterproofing

- Greenish waterproofing materials

- Paint waterproofing simple and affordable

- Impregnation of wood

- Cast method – a reliable barrier to water

Wood floors can be different: parquet, plank, as well as flooring from plywood, chipboard, fiberboard, OSB.

To protect the floor from the effects of water, film and penetrating materials are used, because the tree has a porous structure, it is able to absorb both moisture and liquid waterproofing materials. The task of waterproofing materials is reliable and continuous protection. Seams, tears and joints of the waterproofing material are unacceptable, because in case of water ingress the floor will simply rot. In places where the floor is in contact with the wall, the waterproofing is not interrupted – a protective layer must be applied to a height of 30 cm from the floor.

Classification of floor waterproofing

- okleechnaya;

- painting;

- impregnating;

- cast.

Nakleechnaya waterproofing of a wooden floor with a foil surface

Greenish waterproofing materials

Okleechnaya waterproofing is a so-called “carpet”, consisting of several layers of bitumen-polymer, polymer, as well as bitumen materials.

Before applying the material, a preliminary primer is required..

Paint waterproofing simple and affordable

Painting waterproofing is the application of several layers of bitumen or polymer varnishes on a wooden floor. This method is affordable and simple to implement, but has a significant drawback – cracks appear in the protective layer at low temperature in the room. Paint waterproofing is short-lived, even at normal temperature it gradually loses its useful properties and requires updating every 5-6 years.

Paint waterproofing “closes” the pores of the wood, preventing the penetration of moisture

Impregnation of wood

Wood is a porous material. To give the material a higher density, it is impregnated with special binders. As an impregnation, traditional materials can be used – drying oil, tar or modern – based on silicone, acrylic, synthetic resins. The difficulty is that such impregnations must be applied to a completely dry base. This method of waterproofing is called impregnation.

Cast method – a reliable barrier to water

The cost of cast waterproofing is high, it is difficult and technical performance. But it is the high-quality performance of cast waterproofing that protects the wooden floor from many problems for a long time. Let us consider in more detail the technology for creating cast waterproofing.

Cast waterproofing floors – an expensive, but the most effective way

A layer of sheet or roll waterproofing (roofing material, hydroglass, or other waterproofing materials reinforced with polyester or fiberglass) is laid on a primed and properly prepared base. Sheet or roll waterproofing can be welded with a gas burner or glued with a cold method. After installing the waterproofing, the floor is screed with cement mortar with the addition of water glass. The screed is reinforced with a metal mesh. The surface thus obtained is covered with an additional layer of waterproofing – based on a waterproof cement composition. For extra strength (the waterproofing layer is extremely unstable to abrasion), after drying, a special substrate under the wooden floor should be spread.

Waterproofing the floor in a wooden house

Protecting wood from the harmful effects of moisture in a wooden house is the most important issue; take full responsibility for the choice of waterproofing material and the quality of work. If there is no basement in a wooden house, then as a waterproofing material, roofing material or roofing can be used, it is laid between a tree and a concrete foundation.

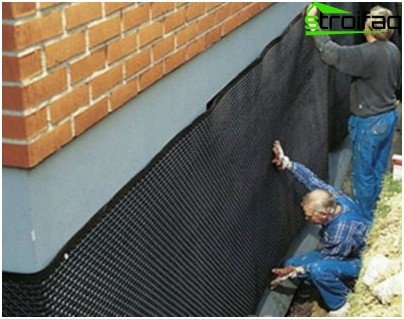

When a wooden house is installed on a foundation with a basement, it is important to ensure reliable waterproofing when laying the foundation. Foundation waterproofing aims to prevent moisture from entering the soil.

How to protect the foundation

Foundation waterproofing protects the foundation and floor from groundwater

To this end, the concrete foundation is covered outside with waterproofing materials – liquid or film. The basement in this case will be dry, one source of moisture for the wooden floor is less.

The front surface of the parquet board or laminate is already protected from water, additional waterproofing is not required. But if you have to lay a wooden floor or a floor from wood slabs, additional waterproofing is required. There must be an air space between the floor and the foundation (so that the floor is warm). Hardwood floors and plank floors are laid on the logs. Naturally, the space between the foundation and the floor must be dry, in order to avoid infection of the tree with fungi and mold. Foundation waterproofing is a prerequisite for reliable insulation of a wooden coating from moisture.

Depending on the purpose, they distinguish between anti-filtration waterproofing of the foundation (protection against groundwater) and anti-corrosion waterproofing. Anti-filtration waterproofing is suitable for basements, as well as for rooms with high moisture aggressiveness, as well as increased pressure load. Corrosion-resistant insulation of the foundation must be used in all other cases. Depending on the material used, it can be glued, filled, impregnated, plastered or mounted. Any of the above methods can protect the foundation from the inside..

Waterproofing the floor on the logs

In cases where waterproofing of the horizontal surface is not possible and the floor is installed “on the ground”, brick posts for logs should be built on the ground. To protect the lags from moisture above, lay pieces of roofing felts, roofing felt or polyethylene (make sure that they are larger than the size of the columns by 4 cm). The voids are covered with gravel with bitumen impregnation and carefully tamped.

This is followed by the installation of a lag (a wooden structure intended for flooring plank floors or floors made of wood boards). Important! – The lags should be thoroughly dried (humidity not more than 12%) and treated with an antiseptic. During the work on the flooring of wooden floors, the temperature in the room should not be lower than + 70C, and air humidity should not exceed 50-60%. With high humidity, the wooden coating can deform – “swell”, and with low humidity – the tree tends to dry out, cracks can form on the surface.

The installation of lags is followed by the laying of a wooden floor. But first you need to take care of the water protection of the tree.

You can apply a polymer or bitumen varnish (the simplest and most economical way). Dissolved bitumen has a useful property – to lay down on a tree with a continuous membrane, which is able to taper and expand with seasonal deformations. The method of applying bitumen or polymer varnish is simple: using painting tools – rollers, flute brushes, spray guns. The protective layer obtained, in addition to its strength and water-repellent properties, also has heat-insulating properties, which is important.

Priming varnishes give a certain shade to the wood, improve permeability between the parquet layer of varnish and the wooden surface, and also serve as a waterproofing of the wooden floor. Impregnation of the upper layers of wood fibers with a primer varnish contribute to the bonding of the fibers, which gives the wooden floor additional impact resistance. Various wood stains, in addition to providing saturation and clarity of color, also help to protect the surface from moisture. Parquet varnishes also serve as additional waterproofing, in addition to their decorative functions. Usually several layers of varnish provide a tight, waterproof coating..

Wood is a material very sensitive to changes in the microclimate, especially sensitive to temperature changes, as well as to changes in room humidity indicators. It is not only a matter of possible deformation of the material: wet wood is a beneficial environment for the development of mold and fungi, causing various chronic diseases and allergic reactions in the inhabitants of the house. To prevent an unpleasant prospect, it is important to properly organize a set of measures to protect the wooden floor from moisture.