Do-it-yourself waterproofing the foundation

Ground, capillary and rainwater undermine the foundation, contribute to its subsidence and deformation. So what needs to be done so as not to leave the least chance to such destructive processes? It is waterproofing, an extremely important stage of construction, that will protect residential and non-residential buildings from moisture accumulation, after the foundation is built – the support and the main bearing element of the structure. It cannot be argued that this technology does not require any special knowledge and experience, but subject to certain rules, waterproofing the foundation with your own hands is quite possible. At the same time, money will be saved on attracting specialists to work.

Content

- The initial stage of creating a waterproofing system

- Types of waterproofing the foundation

- Classification of waterproofing protection by application method

- Waterproofing a monolithic plate

- Foundation water protection

- Bitumen mastic treatment

- Application of roll material

- Sprayed type of waterproofing

The initial stage of creating a waterproofing system

So, of course, when building waterproofing, you must adhere to building codes and standards. Before answering the question: how to properly waterproof the foundation, it is necessary to decide on the type of waterproofing and materials suitable in each individual case. Therefore, when choosing them, you need to consider a number of specific conditions:

– ground water level;

– heterogeneity of the soil;

– the strength of frost heaving;

– operating conditions of the structure;

– type of foundation.

Important: when considering this process from the point of view of material consumption and laboriousness of work, a monolithic foundation is most preferable, since there are no connecting seams that need to be filled with cement mortar.

Many people who are unfamiliar with the foundation waterproofing technology or who are faced with such a process for the first time are wondering if foundation waterproofing is needed or if one can do without a blind area. There is only one answer, waterproofing is needed, because the foundation needs to be protected from surface water, in the form of precipitation, and groundwater, that is, groundwater.

The blind area protects the foundation from the harmful penetration and negative effects of surface water. So, before waterproofing, you should think about how you can divert water from the foundation. For this purpose, blind areas are built, and in particularly problematic cases, a drainage system may be required..

Types of waterproofing the foundation

There are several types of waterproofing:

– horizontal – protection of walls against capillary absorption. Basically, its essence is that two independent horizontal type waterproofing systems are arranged. The first is under the basement, and the second on top of the foundation slabs, at the points of support of the walls;

– vertical – it is located in the zone that begins at the bottom of the foundation structure, and ends with the level of rainwater (when sprayed). The technology of such waterproofing should be calculated at the beginning of construction, when the foundation pit falls asleep. Namely, it is necessary to take into account the layer thickness, soil, the installation of specific protection in the form of asbestos cement sheets, polystyrene foam boards.

Vertical and horizontal waterproofing

Classification of waterproofing protection by application method

Depending on the method of application, they distinguish waterproofing adhesive, plastering, plastering and mounted.

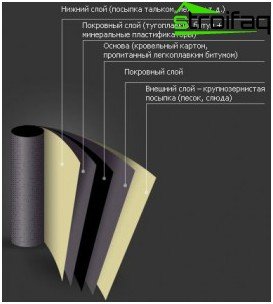

The glucose waterproofing, in fact, consists of waterproof multi-layer membranes with a density of up to 5 mm, as well as polymer-cement bitumen films (self-adhesive). As a similar waterproofing, roofing material, glassine, roofing is used. It is used to protect concrete, reinforced concrete and brick structures. It is applied easily, for this you need to heat the material with a gas burner, then press it firmly against the wall, and then smooth it with a roller. This type of waterproofing perfectly copes with the appearance of cracks and humidity, but there is one drawback – additional pressure walls or screeds are needed.

Okleechnaya waterproofing the foundation

Membranes with waterproofing up to 3 mm thick are arranged. The best materials, in terms of ease of use and affordable price, are bitumen and bitumen-containing components. They are applied with paint graters, spatulas or with a spray. Since bitumen becomes brittle at zero temperature and loses its elasticity, the life of such materials is limited to 6-7 years. Yes, and you need to work with them in a hot state.

Also today there are many varieties of synthetic resins, polymers. For example, bitumen-polymer and bitumen-rubber mastics. They are applied in the cold state, this fact greatly simplifies the waterproofing process. Another example of coating waterproofing is cement-polymer mastics, they consist of dry cement, with the addition of mineral filler. The cement component provides good adhesion to the foundation, and the main task of plasticizing additives is to use in places that are subject to deformation and vibration..

Waterproofing mastics

Plaster waterproofing consists in applying several layers of mortar up to 2.2 cm thick. In this case, a mineral-cement mortar is used, which includes additives that increase moisture resistance, polymer concrete and asphalt mastics. This type of waterproofing remarkably protects the foundation from capillary absorption, but there is also the possibility of cracks, so it should be applied only hot.

The creation of protective shields is the principle of mounted waterproofing. The compacted clay, which should be laid in a layer of 40-50 cm, is the most affordable and widespread material for this type of waterproofing. Bentonite clay is also used, which serves as a protective screen, with a layer thickness of 1-2 cm. A layer of bentonite is placed between the sheets of cardboard or geotextile. During operation, the cardboard shell breaks up, and the surface of the foundation is surrounded by clay. Such clay is produced in the form of insulating panels or mats..

Membrane waterproofing of the foundation

Another excellent protective screens are polymer geomembranes. Such a screen consists of a studded web and filter textile. Rounded spikes create drainage channels, through which water enters the drainage system, and textiles provide full functioning, since it protects the system from siltation. Advantages of these membranes:

– durability;

– neutrality to hostile environment;

– resistance to soil movement and structural deformation.

But there are also some disadvantages of such waterproofing: when groundwater rises above the level of the outlet pipes, then the drainage screens cease to function.

The foundation waterproofing device also depends on the type of foundation itself.

Waterproofing a monolithic plate

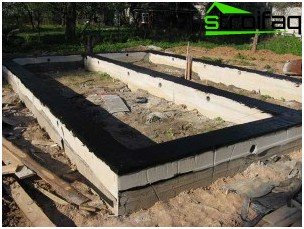

It is preferable to waterproof this type of foundation with a rolled roofing material, which is laid on the foundation slabs. A heater lays on top of the roofing material, since insulation and waterproofing of the foundation are important components of any construction. Then, a screed is made on the insulation, and the floor covering is already laid on it.

Waterproofing the slab foundation with roofing material

Important: if the surface of the plate is uneven, then you need to make a leveling screed.

Foundation water protection

How to waterproof the foundation of the tape type? Such a foundation is waterproofed in several ways:

Bitumen mastic treatment

Bitumen mastic is the most economical option. It is suitable in such cases: for high-quality protection against capillary rise of groundwater and from the penetration of surface waters. But the coating will not protect against pressure water, since it does not withstand a set of more than 2 m. It is applied on a flat surface, previously dried..

Waterproofing with bituminous mastic

Important: such waterproofing needs protection against mechanical damage that usually occurs when backfilling a foundation pit, since it contains construction debris.

As protection is suitable:

– rolled geotextiles;

-brick clamping wall;

– EPPS insulation.

Application of roll material

Ruberoid – the material is a bit more expensive than coating. But then it is more durable and durable. The foundation is being processed with hot bituminous mastic, on which 2 layers (minimum) of roofing felt panels are glued, necessarily with an overlap of 10-20 cm.

Waterproofing roll material

Sprayed type of waterproofing

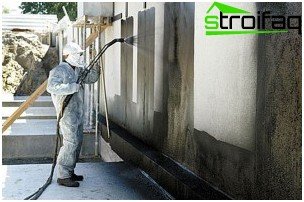

The application of such waterproofing is quick and easy due to the use of a special spray. This is a more expensive material that needs to be reinforced with thermally bonded geotextile material..

Sprayable waterproofing

The cost-effective use of this method of waterproofing for foundations of complex configuration or if the foundation is laid very close to another structure.

Column and pile foundation protection

It is extremely difficult to waterproof the poles and piles. This process takes a lot of time and effort. Therefore, it is advisable to make piles and poles of moisture-resistant concrete. Well, wooden piles need to be treated with an anti-corrosion solution.

Thus, we can come to the correct conclusion that high-quality waterproofing is a guarantee that the construction project, namely the foundation, will not be exposed to the harmful effects of precipitation and groundwater. You just need to take into account all the features of the building structure and properly perform the process.