Do-it-yourself strip foundation

All people are probably familiar with the concept of “underground part of the structure”, that is, the foundation, which takes the load and transfers it to the base. The foundation can be of several types, among them the strip foundation with its own hands is very popular in private construction, because quite reasonable costs are involved in its construction, and the implementation technique is simple. The device of the strip foundation is a fairly simple process, the main thing is to study some technological features. It is advisable to lay this type of foundation with a shallow method of laying on dry non-porous soils, and if the soil deeply freezes on the site, the construction of a strip foundation is more expensive due to the large amount of excavation.

Content

- Strip foundation – application

- Band type foundation life.

- Types of structures used in building construction.

- Types of strip foundations.

- Building materials for the construction of a strip foundation.

What is a strip view of the foundation? This is a specific strip of reinforced concrete, running along the perimeter of the entire house. Such a tape is laid under the outer and inner walls of the building, but at the same time, the cross-sectional shape should be the same along the entire perimeter.

Strip foundation design, scheme

Strip foundation – application

- monolithic, prefabricated reinforced concrete and metal types of strip foundations are used for buildings with heavy floors;

- for structures with brick, concrete and stone walls – density > 1000-1300 kg / cubic meter;

- with heterogeneous soils, if there is a risk of uneven settlement of the foundation. Then the strip foundation acts as a single structure that redistributes efforts, which means that the walls of the house will not be deformed and there will be no cracks;

- in houses with a basement or a basement, walls of a similar type of foundation form a basement wall.

The choice of the type of foundation is a crucial moment, since it is an important structural element of the entire building. If a mistake is made at the beginning of construction, that is, the foundation will be improperly planned, or the building material is saved, then there can be no serious consequences.

The foundation may skew, horizontal or vertical deformations, sediments and cracks in the supporting structure. Reliability of the foundation – a guarantee of capitality and durability of the structure.

Band type foundation life

This indicator directly depends on the building material used:

- rubble cement mortar and monolithic concrete – up to 150 years;

- prefabricated concrete tapes – 50-75 years;

- brick strip foundation – 30-50 years

Types of structures used in building construction

Depending on the design features, strip foundations are divided into:

- monolithic, that is, made on a construction site;

- prefabricated, made of reinforced concrete slabs, which are manufactured at the factory and mounted on the construction site using a crane.

Types of strip foundations

The choice of foundation shallow or deep depends on the degree of load. A shallow-footed strip foundation with one’s own hands is optimally suited for light structures: wooden houses, foam-concrete and frame houses, as well as small brick ones. It settles down on slightly downy soils, its depth is about 50-70 cm.

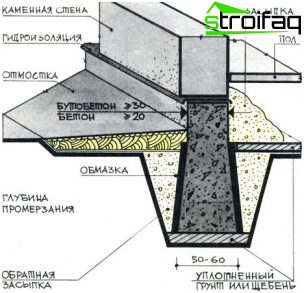

At the same time, for structures with massive ceilings and walls, a recessed strip foundation is used, mainly on heaving soils. In addition, this type of foundation is necessary when planning a basement or garage in a house. Its construction requires more significant costs of materials and its depth is 20-30 cm below the freezing point of the soil. Under the walls inside the building, a shallower depth of 40-60 cm is possible..

Building materials for the construction of a strip foundation

- The concrete foundation is a sand-cement mixture with the addition of large stones. This is a fairly reliable foundation, with a width of 200 mm – 1000 mm. Its device requires the creation of a sand or gravel cushion, not less than 100 mm thick, for leveling the soil and for convenient laying of the mixture.

- Brick strip foundation is used for the above- and underground parts of the foundation, for basement parts. But during its construction, you need to remember: the brick material is hygroscopic and in the wet state is destroyed even in small frosts, so it needs waterproofing. The brick view of the strip foundation is suitable for houses with walls of one to one and a half bricks or with a wooden frame.

- Reinforced concrete strip foundation – a mixture of sand, gravel, cement, reinforced with reinforcement rods or metal mesh. This is the most common material, because it is quite cheap, durable and makes it possible to create monolithic structures of the most complex configurations. If the site is sandy, then this is an excellent choice of material.

- Foundation blocks and plates – strong, reliable, they are suitable for almost all types of buildings and all types of soil.

The technology of construction of a strip type of foundation

Important: the choice of workers is a crucial moment that should not be ignored, because the human factor in construction occupies significant positions

The shallow strip foundation provides for the use of building materials such as reinforced concrete and but concrete.

The construction of a strip foundation with your own hands, namely shallow, consists of the following main stages:

Preparatory work – clearing, marking

Preparation for the construction of the strip foundation – clearing the site, marking the future foundation

This is the clearing of the site and the delivery of all necessary materials. The axes of the house are marked on the ground, and the location of the basic elements of the future foundation is also fixed with the help of stakes and a cord.

This operation must be carried out accurately and carefully, it is necessary to check the angles, which must be necessarily 90 degrees, and the mark of the bottom of the trench must also be checked (at the corners and at the intersection points). The leveled construction site should be larger than the size of the house (in each direction > 2-5 m).

Trench – development for formation

Trench for the installation of a strip foundation with shallow depth

The trench is digging either manually or by an excavator. In the latter case, the bottom of the trench must be cleaned and leveled by hand. The foundation pit is further protected, and a pillow (120-200 mm) made of fine gravel or sand is laid at the bottom of the trench. It is watered and carefully tamped. A plastic film is placed on this pillow as a waterproofing material, or it is poured with cement mortar so that the water does not go into the ground and the strength characteristics of the pillow do not deteriorate.

Arrangement of formwork, its varieties

Formwork for such a foundation is made of boards (planed on one side) with a thickness of at least 40-50 mm. And also widely applicable panel collapsible formwork (iron). Installed formwork with spacers is securely fixed to the walls of the trench. It is extremely important to carefully calibrate the verticality of the walls with a plumb, because the period of operation of the foundation depends on the accuracy of this indicator. And also you must not forget about the holes for the sewage system and water supply.

Installation of fittings – load-bearing structural elements

Simultaneously with the arrangement of the formwork, the assembly of fittings assembled into frames is also carried out. The number of rods, their location and diameter are indicated in the project. In general, this frame consists of two strips of vertical reinforcement fastened with horizontal rods. How many of these rods will be depends on the depth of the foundation.

Pouring concrete

Pouring concrete through the gutter into the formwork

Important: you need to remember that the concrete mix, when pouring from a height of more than 1.5 m, undergoes delamination. Therefore, it is desirable to use a portable gutter

At this stage, concrete is gradually poured into the formwork, in layers of 15-20 cm thick. In addition, each layer is rammed so that voids do not form. And also for this purpose, the formwork walls are tapped. Important – the concrete solution must be hard, but not liquid.

Foundation waterproofing

7-10 days after pouring, the formwork is removed. For foundation waterproofing bitumen mastic is used, the outer walls are smeared with it and the waterproofing material is glued. A wonderful material for waterproofing is roofing material. After some time, the quality of the gluing is checked, that is, does the waterproofing peel off from the walls of the foundation.

Waterproofing – a guarantee of reliable service

Backfill – Shutdown

At this stage of construction, backfilling of the foundation sinuses (medium-sized sand) should be performed. It is layered in layers and filled with water. At the same time, it is necessary to monitor the state of the waterproofing so that it remains safe and sound..

Possible errors and their consequences

- Soil properties are not taken into account, groundwater level and freezing depth are not determined – cracks and sediment.

- Poor quality materials and poor performance of the entire spectrum of work – poor and short-lived foundation.

It goes without saying that such errors should not be. Therefore, the approach to the construction of the strip foundation should be meaningful and reasonable. After all, building a house is a large-scale work, therefore, at the very first stage, as well as at all the others, there should be no mistakes and errors in calculations and construction processes.