Technological scheme of reinforcement and calculation of reinforcement

Foundation reinforcement is the process necessary to strengthen the structure and increase the life of the building. In other words, this is the assembly of the “skeleton”, which plays the role of a protective component that restrains the pressure of the soil on the walls of the basis. But in order for this function to be realized to the maximum extent, it is necessary not only to correctly calculate the reinforcement for the strip foundation, but also to know how to organize the progress of construction work.

Content

- How to reinforce a strip foundation

- Reinforcement structure diagram

- Calculation of material consumption

How to reinforce a strip foundation

The foundation of the tape-type foundation is a concrete mortar consisting of cement, sand and water. Unfortunately, the physical characteristics of the building material do not guarantee the absence of deformation of the base of the building. To increase the ability to withstand foundation shifts, temperature changes and other negative factors, the presence of a metal in the structure is necessary.

This material is plastic, but provides reliable fixation; therefore, reinforcement is a significant stage in the complex of works.

Reinforcement for strip foundations – steel bar with stiffeners

Foundation reinforcement is required in places where tensile zones may occur. It is noted that the greatest tension appears on the surface of the base, which creates the prerequisites for reinforcement close to the upper level. On the other hand, in order to avoid corrosion of the frame, it must be protected from external influences by a concrete layer.

Important! The optimal distance of reinforcement for the foundation is 5 cm from the surface.

Since it is impossible to predict the progress of the deformation, extension zones can occur both in the lower part (when the middle bends down) and in the upper (when the frame bends up). Proceeding from this, reinforcement should pass from below and above by reinforcement with a diameter of 10-12 mm, and this reinforcement for a strip foundation should have a ribbed surface.

This makes perfect contact with concrete..

Strip footing zones

The remaining parts of the skeleton (horizontal and vertical transverse rods) may have a smooth surface and a smaller diameter.

When reinforcing a monolithic strip foundation, the width of which usually does not exceed 40 cm, it is allowed to use 4 reinforcement rods (10-16 m) connected to a frame with a diameter of 8 mm.

Important! The distance between horizontal rods (with a width of 40 cm) – 30 cm.

The tape foundation has, with a large length, a small width, therefore, longitudinal tension will appear in it, while there will be no transverse ones at all. From this it follows that the transverse vertical and horizontal rods, which will be smooth and thin, are needed only to create a frame, and not to take loads.

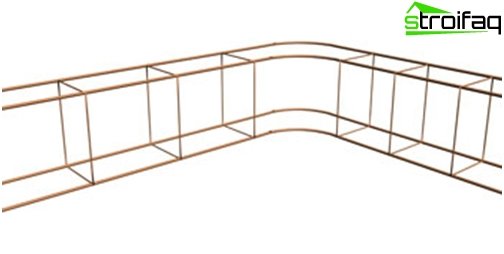

Corner reinforcement needs special attention

Particular attention should be paid to reinforcing corners: there are cases when deformation occurs not in the middle, but in the corner parts. The corners should be reinforced so that one end of the bent reinforcement goes into one wall and the other into the other.

Specialists advise connecting rods using wire. After all, not every grade of reinforcement is made of steel that can be welded. But even if welding is acceptable, problems often arise that can be avoided using a wire, for example, overheating of steel, leading to a change in properties, thinning of the rod at the weld site, insufficient strength of the weld, etc..

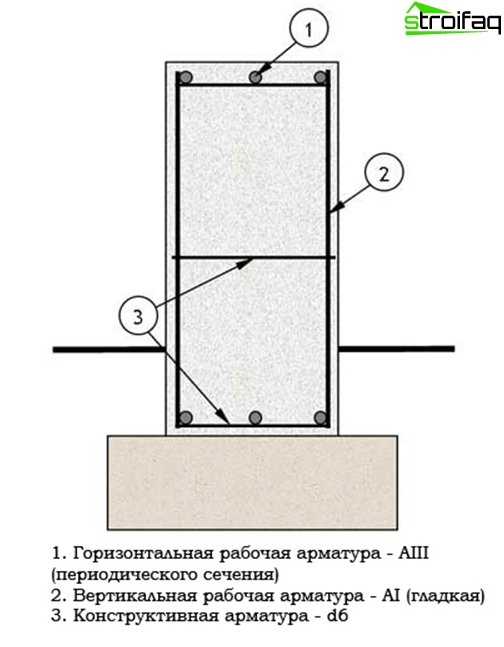

Reinforcement structure diagram

Reinforcement begins with the installation of formwork, the inner surface of which is laid out with parchment, which allows to simplify the removal of the structure in the future. Creating a frame is made according to the scheme:

1. Reinforcing bars with a length equal to the depth of the base are driven into the soil of the trench. Keep a distance of 50 mm from the formwork and a pitch of 400-600 mm.

2. On the bottom set supports (80-100 mm), on which you need to lay 2-3 threads of the bottom row of reinforcement. The bricks mounted on the edge are quite suitable as supports.

3. The upper and lower row of fittings are fixed together with the transverse jumpers to the vertical pins.

4. At the intersection, fasten by wire or welding.

Important! The distance to the outer surfaces of the future foundation should be strictly observed. Do it better with bricks. This is one of the most important conditions, as metal structures should not be based directly on the bottom. They must be raised at least 8 cm above the ground.

Strip foundation reinforcement

After installing the fittings, it remains to make ventilation holes and pour concrete mortar.

You need to know!

Ventilation holes not only contribute to the depreciation of the foundation, but also prevent the emergence of putrefactive processes.

Calculation of material consumption

For the calculation of the strip foundation, you need to know some parameters in advance. Consider an example. Suppose our foundation has a rectangular shape and the following dimensions: width – 3.5 meters, length – 10 meters, casting height – 0.2 meters, belt width – 0.18.

First of all, you need to calculate the total volume of the casting, for which you need to find out the dimensions of the basis as if it had the shape of a parallelepiped. To do this, we will make a few simple manipulations: we will find out the perimeter of the base, and then multiply the perimeter by the width and height of the casting.

P = AB + BC + CD + AD = 3.5 + 10 = 3.5 + 10 = 27

V = 27 x 0.2 x 0.18 = 0.972

But the calculation of the monolithic foundation does not end there. We learned that the base itself, or rather casting, occupies a volume rounded equal to 0.97 m3. Now you need to find out the volume of the inner part of the foundation, i.e. of what’s inside our tape.

We get the volume of the “filling”: we multiply the width and length of the base by the height of the casting and find out the total volume:

10 x 3.5 x 0.2 = 7 (cubic meters)

Subtract the volume of the casting:

7 – 0.97 = 6.03 m3

Result: the volume of the casting is 0.97 m3, the internal volume of the filler is 6.03 m3.

Now you need to calculate the amount of reinforcement. Let’s say that the diameter will be 12 mm, in the casting – 2 horizontal threads, i.e. 2 rods, and vertically, for example, the rods will be located every half meter. The perimeter is known – 27 meters. So we multiply 27 by 2 (horizontal bars) and we get 54 meters.

Vertical rods: 54/2 + 2 = 110 rods (108 intervals of 0.5 m and two at the edges). We add one more rod to the corner and we get 114 bars.

Let’s say the height of the rod is 70 cm. It turns out: 114 x 0.7 = 79.8 meters.

The final touch is formwork. Suppose we will build it from boards 2.5 cm thick, 6 meters long and 20 cm wide.

Calculate the area of the side surfaces: multiply the perimeter by the casting height, and then by 2 (with a margin, not taking into account the decrease in the inner perimeter against the outer): (27 x 0.2) x 2 = 10.8 m2

Board area: 6 x 0.2 = 1.2 m2; 10.8 / 1.2 = 9

We need 9 boards 6 meters long. Do not forget to add boards for connection (at your discretion).

Result: 1 m3 of concrete is required; 6.5 m3 aggregate; 134 meters of fittings and 27 linear meters of boards (20 cm wide), screws and bars. Values shown are rounded..

The results of painstaking settlement work

Now you know, not only how to properly reinforce the strip foundation, but also how to calculate the necessary components. And this means that the foundation built by you will be reliable and strong, allowing the construction of monolithic structures of any configuration.