Foundation for the furnace

Currently, there is a wide selection of finished metal stoves for baths, welded from steel sheets and cast iron. However, brick stoves, which decorate the bathhouse with their massive shapes and retain heat for a long time, do not give up their positions. In any case, it is necessary to install the foundation for the furnace before installing the furnace structure, the dimensions of which depend on its weight. Correct calculation and compliance with the technology of erecting a foundation foundation will protect the furnace from distortions, the occurrence of cracks in the masonry, the complete destruction of the structure.

Content

- Calculation of the foundation for a brick furnace

- Stages of the construction of the foundation for the furnace

- Scheme for the device base

- Column design of the furnace foundation

- Installation of piles for the foundation

Calculation of the foundation for a brick furnace

The length, width and depth of the foundation base depend on the dimensions of the future furnace and its weight. For an approximate assessment of this indicator, it is necessary to remember that one cubic meter of brickwork pulls approximately 1350 kg. In this value, the weight of bricks and mortar going to seal horizontal and vertical joints is already taken into account. Knowing the volume of the furnace, it is easy to calculate its weight by multiplying this value by 1350. If the weight of the furnace structure does not exceed 750 kg, then you can do without a separate foundation. Such small stoves usually take no more than 200 pieces of bricks. Therefore, as their base, a sheet of asbestos is used, laid on a clay solution, on top of which a sheet of roofing iron is placed.

Reliable foundation for the stove in the bath, made of brick should be located below the level of soil freezing in the area. In this case, the influence of seasonal soil movements on the furnace structure can be avoided, since there will be a solid, artificially constructed base.

Important! The depth of soil freezing in each region has its own values. To find out the exact information on this issue, you must use the reference literature.

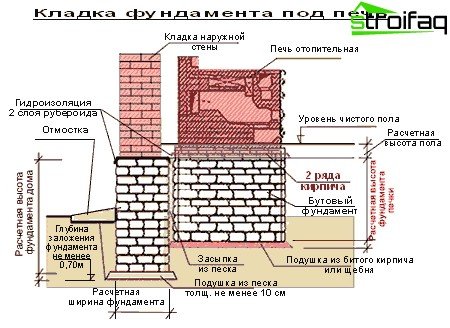

Stages of the construction of the foundation for the furnace

- Work begins with digging a foundation pit, leveling its base and laying a sand-gravel layer. After tamping, they arrange a sole, using broken bricks or gravel. Next, the sole is poured with a liquid cement mixture.

- Next, masonry of full-bodied bricks or rubble stones is carried out, while ensuring that the rows are smooth and regular. Do not forget about the need for dressing the stitches. The outer rows are laid on cement mortar under the scapula, and the inner rows are clogged. The upper platform is leveled by applying a cement layer. It is necessary to achieve perfect horizontal surface, so all work is carried out using a rule with a level.

- To protect the bath stove from the penetration of groundwater, be sure to lay a double layer of roofing material, which serves as an excellent waterproofing.

- After they spread another one or two brick rows to the floor level. It can be considered on this the foundation device ends. He is given time to dry and achieve strength. Next, they carry out bricklaying.

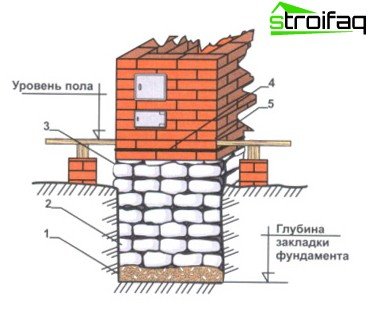

Scheme for the device base

- Crushed sole.

- Underground Masonry.

- Top cut.

- Waterproofing layer.

- Furnace masonry.

Layout of the foundation for the stove in the bath

Important! The foundation for a bath stove is by no means combined with the foundation foundation being erected for the walls of the bath. Even at close proximity they leave a gap of several centimeters, which is covered with sand or small gravel.

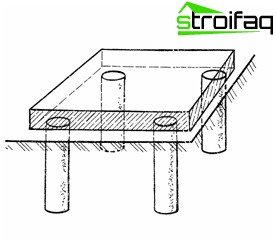

Column design of the furnace foundation

The columnar foundation for the furnace reduces the volume of earthwork and helps save materials.

In addition to the installation of poles at the four corners of the furnace, it is necessary to carry out installation of the base installed on these supports. As a base, you can use a finished reinforced concrete slab or frame, which is welded from steel profiles. At the same time, remember that the stove should be larger in size of the furnace, which allows it to better hold the weight of the furnace structure.

Column design of the furnace foundation

Pillars or piles acting as a reliable support for the foundation slab allow avoiding the effects of seasonal soil movements resulting from heaving of clay and loamy soils during severe frosts.

Installation of piles for the foundation

- Cylindrical holes are drilled to the required depth in the soil, the diameter of which is about 20 cm.

- A crushed stone layer 10-15 cm thick is poured at the bottom of the obtained pits. The crushed stone is carefully tamped.

- In the drilled holes, tubes of roofing material are inserted, which serve as the formwork.

- Pour concrete mixture.

- Leave concrete pillar piles for ten days to dry.

- After the expiration of the allotted time, they begin to install the reinforced concrete slab.

- A waterproofing is arranged along the top edge of the foundation, using the same roofing material, coated with hot bitumen and laid in two layers.

Important! To ensure free shrinkage, a gap must be left between the base and the ground..

If the characteristics of the soil allow the use of a finely buried foundation, then the slab is laid in a shallow trench on compacted crushed stone. In this case, the installation of piles can be avoided. And reduce the cost of the foundation for a brick oven.

The foundation for the furnace in the form of a reinforced concrete slab is a standard reliable option that can withstand units with any weight

The foundation of concrete

- Pit is marked out, the dimensions of which must exceed the calculated indicator by 10-15 cm.

- Next, a 15-centimeter layer of crushed stone is poured and compacted with a special hand tool.

- The formwork is made of boards, which is a box without a bottom, equal in size to the future foundation.

- The walls of the formwork are waterproofed from the inside, for which they are lined with roofing material.

- A layer of large stones is laid on the base, the optimum value of the diameter of which is no more than 15 cm.

- The voids between the stones are covered with rubble.

- The layer is poured with a cement-sand mortar prepared in a ratio of 1: 3. The solution by consistency should resemble thick sour cream. If the area of the foundation is large, then the second layer of stones is laid out only after a day. Otherwise, all work is carried out in one day..

- The fill of the structure is completed at the moment when seven centimeters remain to the level of the finishing floor. The surface is carefully checked by the building level for horizontalness. In case of deviations, cement mortar is added until the device shows the desired result.

- The leveled and smoothed foundation surface is covered with polyethylene and left for a week for the concrete to dry completely.

- After completion of work on the foundation foundation device, the formwork is dismantled.

- Melted tar in two layers is applied to the sides of the base..

- The gaps between the walls of the pit and the foundation base are covered with fine gravel or coarse sand.

Features of laying the foundation for the furnace

Important! For the preparation of the solution, Portland cement grades of at least 400 are purchased.

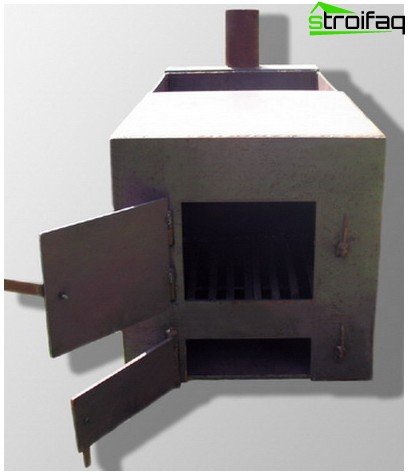

Base for a metal bath stove

Many beginner builders are wondering how to make a foundation for a furnace made of sheet steel.

The weight of such finished ovens usually does not exceed 150 kg.

For a metal stove for a bath, a foundation will also be needed

In this case, the foundation is performed as follows:

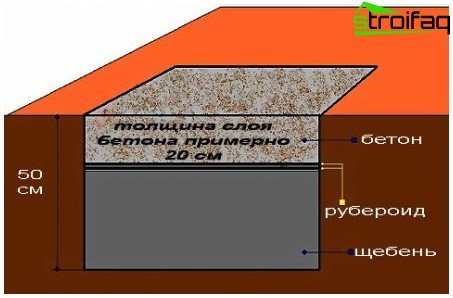

- dig a pit, the depth of which is half a meter, and the width and length depend on the dimensions of a particular metal furnace;

- a 30-centimeter layer of crushed stone is poured onto the leveled bottom, which is carefully compacted;

- a cement-sand mortar prepared on the basis of: one part of cement – four parts of sand is poured over a compacted crushed stone layer; water is added as necessary until it reaches a creamy consistency;

- work is suspended for a day, during which the cement hardens;

- then on top of the hardened layer lay two pieces of roofing material, thereby providing foundation waterproofing;

- after that, the foundation pit is poured with concrete mixture and the level of the surface is checked for level;

- with the help of red burnt bricks make several rows of masonry, thereby bringing the foundation to the level of a clean floor.

Foundation scheme for a metal bath stove

Important! The concrete mixture is prepared from cement, sand, fine gravel and water, and the first three components are taken in a ratio of 1: 2.5: 4.

The fastest and easiest way to make the foundation is to elementary concreting a dug pit. At the same time, under a brick furnace, a reinforcing cage is laid in the pit, which is poured with concrete to the ground level. Sometimes these works are done without formwork. After they report the foundation with a brick, which does not reach the floor level by 10 cm. The surface of the last brick row is leveled with cement mortar. It is covered with two layers of roofing felt or roofing material for waterproofing. Thick dry boards with waterproofing are laid on top or a brick box is being built, the size of which corresponds to the base of the furnace. The box is filled with slag or brick fight.

If the foundation device is carried out in moist soil, then ordinary brick is replaced with iron brick. In this case, the lower part of the foundation base is poured with concrete or concrete, and the upper part is made of brick. At the same time, in addition to sand (9 parts) and cement (1 part), lime dough (1 part) is added to the solution. For dry soils, you can use a clay solution in which cement is added..

Starting to build the foundation with your own hands, do not seek to save on the quality of the materials used. Because the durability of the bath stove, and hence the bath itself, will depend on the strength of this structure. After all, the oven is the “heart” of this structure, healing both the body and soul of man.