Do-it-yourself frame bath

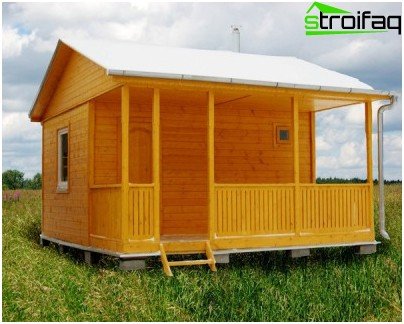

I want to take a steam bath in the bathhouse, but there is no money for the construction of brick and log structures? Then the frame sauna with your own hands is perfect. For its construction, expensive materials and competent drawings are not needed. This option is by far the most profitable in terms of spending money and time. And the benefit is obvious: saving material twice and quick erection.

Content

- List of advantages and disadvantages

- Vapor barrier – design protection

- Thermal insulation – minimum heat loss

- The choice of wood – the current moment

- Stages of the frame bath construction

- Foundation for frame construction

- Bottom harness

- Walling sequence

- Roofing is the next step

- Finishing is the final process

List of advantages and disadvantages

Frame baths have an important advantage – the walls do not shrink, and when using high-quality modern insulation, the structure is very light.

High speed construction, and the technology is specific: you can simultaneously finish the bath outside and inside. The frame is assembled for several days, and finishing work and installation of heating equipment takes a couple of weeks.

Panel-frame bathhouse is a unique type of baths, it is reliable, durable and very popular in Canada, USA. Its service life is less than a brick structure, but an excellently constructed frame building costs more than 100 years. This figure is confirmed by the fact that in Europe there are structures erected 2 centuries ago.

A significant plus is the many options for exterior and interior decoration. For example, on the outside it can be siding, tile, plain board and even plaster.

The specificity of the processes allows you to hide all the equipment in the wall: automation elements, pipes.

And, of course, the project cost of a frame bath is much lower than similar brick and log baths.

Frame sauna has many advantages and few disadvantages

Along with the advantages, there is one drawback – humidity. It penetrates during the rains and snowfalls into the cracks of the structure and can accumulate inside the frame. But knowing the nuances and subtleties of construction processes, you can evade such undesirable phenomena.

Vapor barrier – design protection

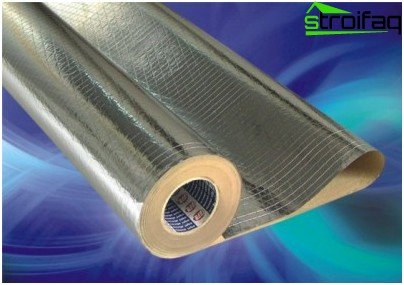

Can condensation be avoided? And how to build a frame sauna that will be used in the winter? Undoubtedly, moisture brings a lot of damage to the general condition of the structure, in order to preserve the initial state of the bath, it is necessary to take care of vapor barrier. For this purpose, glassine and special vapor barrier films are perfect. These materials are placed between the insulation and the inner lining of the room.

A vapor barrier material with a foil side allows vapor to pass through, retains heat

Important: roofing material as a vapor barrier material is undesirable, because when heated it exudes a specific smell.

Thermal insulation – minimum heat loss

The frame bath requires good thermal insulation to ensure tightness and minimize heat loss. Such baths have low thermal conductivity, so the proper organization of the steam room is extremely necessary.

Important: tightness should not impede normal air exchange..

Most often, baths are insulated with mineral wool or fiberglass, as these materials have good thermal conductivity and are considered the best..

The choice of wood – the current moment

The frame bath in the country must be built of dried wood, for example, aspen, larch, linden. These rocks have low thermal conductivity and for a long time retain their original structure. When erecting walls, boards are used (thickness – 2-3 cm), for external cladding, you can take boards from pine and larch, and for the inner one choose another breed option.

Important: with the inner lining, the boards are arranged vertically.

Stages of the frame bath construction

Before proceeding with the construction and creation of the project, you need to analyze the following details:

- location of the future bath: will it be a separate room or a continuation of the building;

- selection of land for construction;

- determination of the type of soil on the site;

After that, you can design a frame bath, that is, determine the location of the furnace, chimney, porch, ventilation and choose the type of roof. Many people want to have good frame baths – projects are an important component, because the more details will be designed, the easier construction progress will be in the future..

Important: when such conclusions cause difficulties, it is better to seek the help of specialists or a construction company.

Foundation for frame construction

Since the frame structure is lightweight, the foundation can be made according to the most simplified scheme. The most suitable option is a columnar foundation of asbestos-cement pipes, which are poured with concrete.

For an easy frame construction, a budgetary columnar foundation of asbestos pipes is quite enough

The essence of the work is as follows:

- acquisition of four-meter asbestos-cement pipes (diameter 100 mm);

- wells are drilled using a gas drill – depth 1.5 m, diameter 200 mm;

- pipes are cut into equal halves and inserted into pre-drilled wells. Then sand is poured around them, later it is carefully compacted.

Important: the grouting solution consists of the following components: cement, sifted sand, fine gravel, water.

- the mixture is filled with installed pipes.

Bottom harness

Usually it is made of several edged boards that are knocked together (cross section 150×50 mm). After the end of this work, logs made of boards cut into the strapping. They are designed for flooring.

At the same time, do not forget about the thorough waterproofing of this part of the building. To do this, under the harness and sex lags, ruberoid segments are laid. To give the structure extra strength, the lags and piping are fixed to the foundation pipes using pre-walled metal plates.

Then, the resulting structure should be treated with a special solution (several times): high-quality protection of wood from insects and rotting is provided.

Walling sequence

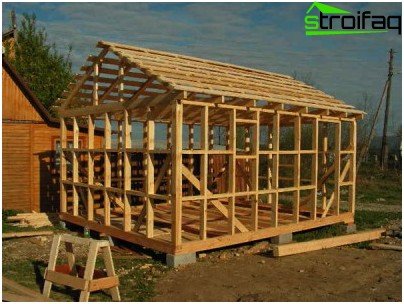

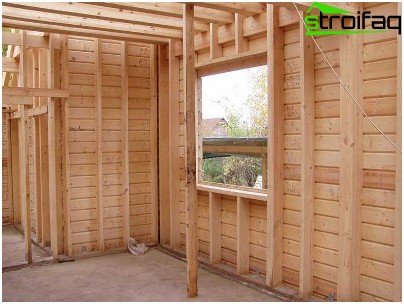

Before this stage, the material should lie down and dry well. Then, according to the project, you need to prepare frame racks and roof truss parts from the same boards.

The frame is ready, it remains to sheathe and trim

Then the installation location of the frame racks is marked and then you can already begin the final assembly of the frame. Installation takes place in the following order:

- installation of two corner posts and several intermediate;

- from one selected angle the frame is sheathed with oriented particle boards (they are set according to the level and are fixed to the frame with screws);

- installation of several more racks that are sheathed similarly.

In this way, that is, by sequentially adding racks and attaching OSB plates to them, an integral structure is assembled. Of course, one must take into account the openings of windows and doors..

Roofing is the next step

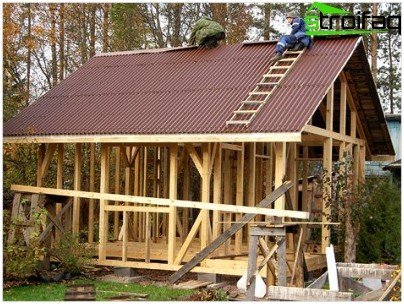

During the construction of the frame bath, all rafter structures are assembled directly on the ground, according to a single template. They take turns rising to the roof, each placed above its counter.

Important: before installing the last farm, you need to mark it – designate the shape of the OSB sheets. They will be sheathed pediment.

For greater practicality in the assembly work, it is desirable to lay on the beams a kind of temporary overlap. For this purpose, ordinary boards are suitable.

Roofing: gable roof ridge devices

The ventilated roof will function best. A special film is placed in the space between the rafters and the rear beam, and the crate is stuffed directly onto the beam. Ondulin is ideal as a material..

When the roofing is completed and the gables are closed (with pre-prepared sheets), it remains to install the window and door blocks in the provided openings.

Finishing is the final process

The construction of a frame bath is not just the creation of a reliable and strong structure, but also the carrying out of finishing work. Outside, it is sheathed with pine or spruce boards. They are mounted in a horizontal position, since this method provides additional rigidity and stability of the bath. Other connection options are also often used, for example, end-to-end placement of boards. Then, a waterproofing layer is laid under the skin, and the space is filled with insulating material.

As for the inner lining, it is a guarantee of protection against environmental influences. The draft ceiling is made from the same OSB sheets that are fixed to the bottom beams.

Important: for insulation, three layers of insulation are laid.

In the area where the steam room is supposed to be, screen foil is placed in the piers, and the remaining walls are closed with a glass.

The interior decoration of the frame bath can be carried out simultaneously with the facade work.

After that, boards turned upside down are beaten to the lags (you can take those that were used as forests). In the steam room, a stove is usually installed, and on the side of the dressing room – a heating boiler.

The fire safety rules should not be forgotten, so the part of the wall that encloses the steam room from the rest room is laid out from building bricks.

As already mentioned, the construction of the frame type is very convenient in terms of decoration, you can carry out work immediately inside and out. For this reason, if there are forced breaks, you can prepare the frameworks of partitions, upholstered them with a blockhouse or lining made of natural wood. So time will not be wasted, but will be spent usefully.

Important: it is advisable to equip the ceiling with a ladder hatch for greater convenience.

In the steam room, the ceiling level can be lowered to an indicator of 2.1 m, this will make it possible to carry out additional insulation and cover it with a “clean” linden lining. Shelf production is recommended from the same material..

Do-it-yourself frame baths are an indisputable advantage: savings, speed of construction and beautiful construction. You can soar in them all year and admire the walls created by your own efforts.