The bathhouse is not only a place where you can have a great time in a close friendly company, steam up and whip each other with brooms, it also performs irreplaceable functions for healing the body. After the correct procedures in the bath, the work of many organs and systems improves: the kidneys, respiratory organs, and excretory system. This is due to the cleansing of the body from toxins, salts, toxic substances, acids and decay products. All this comes out with sweat. Our ancestors went to the bathhouse at least once a week to cleanse the lymphatic system. In order to maximize the healing function, the material for the baths should be natural, minimally processed and useful for the human body. That is why log saunas have always been built.

Content

- Cons and pros of the bath from the logs.

- How to choose wood for a bath from a log.

- How to choose a place to build a bath.

- Laying the foundation for the bath.

- Preparation of logs for laying.

- The erection of walls from logs.

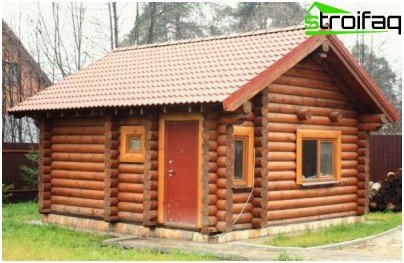

- Baths from a log: photo options, the construction of a log bath

The construction of baths from logs was made from coniferous wood, and the interior was made from aspen, linden, cedar, which have healing properties and fill the interior with pleasant smells of essential oils. Today, despite such a wide selection of building materials: brick, foam concrete block, glued beam, construction of log baths, it continues to personify the traditional “Russian bath”.

Cons and pros of the bath from the logs

Wooden logs have a beautiful natural structure, but this is not their only plus.

Benefits:

- Log walls easily pass steam and air, leaving inside the warmth and wonderful aroma of wood;

- The log bath is more durable, comfortable, less conducts various external sounds;

- A chopped bath will last dozens of years without additional reconstructions;

- The natural layer of the crust of the planed log protects the tree from bacterial decay, infection by fungi and damage by insects. In this case, additional treatment with special impregnations is not needed;

- Log houses of logs can be built according to any architectural design, because the walls can be located at any angle to each other;

- Significantly saved energy resources in order to melt the bath and keep warm, due to the fact that tightly fitted logs practically do not allow heat to pass through;

- Today, log baths are built quite easily and quickly thanks to high-quality processing of logs and fitting to the required exact dimensions;

- Naturalness, environmental friendliness and healing power remain the main advantages of a chopped bath.

disadvantages arise only with an unprofessional approach to construction:

- If the wood is chosen incorrectly, too damp, then in the future there may be a “shrinkage” of the structure, and longitudinal cracks will arise;

- A master of their craft should build a bathhouse from logs, otherwise there is a risk of not getting the expected result and all the above advantages.

Round logs for the bath should have a uniform shade

How to choose wood for a bath from a log

In Ancient Russia, the secrets of building a bath from a log were passed down from generation to generation. Building material was prepared in advance, dried for a long time in natural conditions, so preparation and construction took a lot of time.

From that time to the present day, the following wood species are used for the bath: pine, spruce, cedar and sometimes larch. The best material is pine, harvested in the winter. It is she who has the best moisture resistance indicators. Logs of at least 25 cm in diameter are selected from wood with high density.

Important! When choosing wood for construction, it should be borne in mind that wood of the same variety, but grown in different climatic conditions, has a different density level.

Requirements for wood for a bath:

- Low thermal conductivity;

- Low heat capacity;

- Soft pleasant smell;

- Resistance to splitting;

- Good sound absorption;

- Strength and durability;

- Lack of tar pockets;

- As few knots as possible.

It is recommended that the log house made of logs be made of northern coniferous wood. It has a dense structure and does not change its properties from temperature extremes and an increase in humidity. Pine and spruce from the Baltic Sea and Canadian spruce are best suited. Sometimes high-quality deciduous wood of linden, aspen, alder is used..

What you need to pay attention to when buying logs:

- The surface of the log should have a light or dark yellow hue;

- The branches should sit inside without gaps. If there are gaps, then the core is rotting;

- The cut of the log should have a hard surface;

- There should be no blue spots on the cut;

- The core should be three quarters of the cut and have a dark even shade;

- Hit the ax with the butt on the end of the log, it should bounce and at the same time make a ringing sound.

How to choose a place to build a bath

First of all, you need to go around the site, check where what soil. See where the neighbors, the road, and other key points are. Imagine what I would like to see when I stepped out of the bathhouse.

The entrance to the bathhouse is better located on the south side; snowdrifts here melt faster.

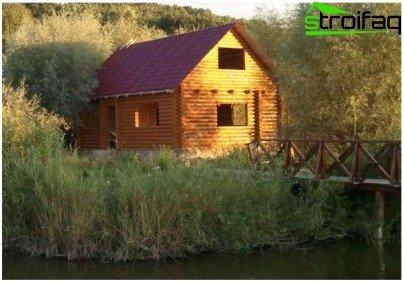

A bath near the river is a good option

If there is a body of water on the site: a lake or a pool, or access to a river, it is advisable to build a bath from a log nearby, but not closer than 15 m, so that during flood.

If there is a road nearby, then it is better to place the bathhouse on the other side of the site, away from prying eyes and exhaust gases.

If you want your neighbors not to see you running out steamed and jumping into the pond, position the bathhouse so that no one can see the doors coming out of it. And it is better to enclose all other viewed sites with a fence or hedge..

If the groundwater is too close, building a swimming pool for a bath is almost impossible, you will have to be content with a font and a shower.

Bathhouse in the forest – clean air and a minimum of neighbors

It is better to hide the veranda or the terrace of the bath from prying eyes. It will be nice to go out with a cup of tea or a decoction of herbs, sit on a bench or just stand on the porch and not catch the prying eyes.

And, of course, do not forget about fire safety standards and sanitary records when choosing a place for a bath.

Laying the foundation for the bath

If your dream is a sauna with your own hands from a log, after choosing a site you must choose what foundation is required for the bath.

First, determine the type of soil at the construction site.

If the soil is marshy, forest or garden, clay, loam, of fine gravel or coarse sand, it is better to build a strip foundation.

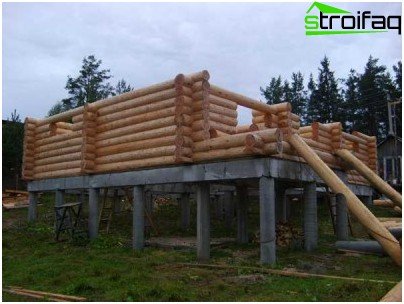

If the ground is heaving, or the building will be located on a slope, a pile or screw foundation made of concrete or metal piles is suitable.

If the soil consists of fine sand, rocky rocks or quartz, any foundation will do..

The column foundation for a log bath is an economical option that can significantly reduce construction costs

If the soil allows, then most often the construction of the bath from logs is done on a columnar foundation. It is made of stone, brick or concrete. Previously used wooden poles, now also sometimes, but they are short-lived. The depth of the column foundation can be from 70 to 100 cm.

For a strip foundation, it is necessary to dig a trench, pour sand into it with a layer of about 15-20 cm. Top with crushed stone with the same layer, lay reinforcement and pour concrete.

Preparation of logs for laying

First of all, the logs must be trimmed “under the bracket”. The difference between the upper and lower diameters should be a maximum of 3 cm. Of course, you can buy finished processed logs at the factory, but they have a significant drawback. With large-scale production, it is difficult to calculate the exact layer that needs to be removed. And with the help of a plane only sapwood is removed, and the protective layer of the tree remains. In this case, the wood is more durable and more resistant to external influences..

We saw the logs along the length of the wall and unpack them. The logs are conical in shape, and it is not always possible to equalize the upper and lower diameters. Therefore, the thickest and thinnest ends are put together in a corner and cut at a right angle.

Deviations in the size of the logs should be in the range of 1-3 cm, otherwise they will not fit snugly together.

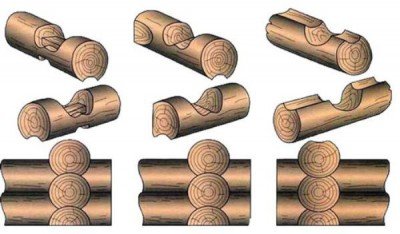

A bath made of logs involves joining logs with special grooves. We select the wood with an ax until a groove appears. Then we cut down the “paws” and check the density of their fit.

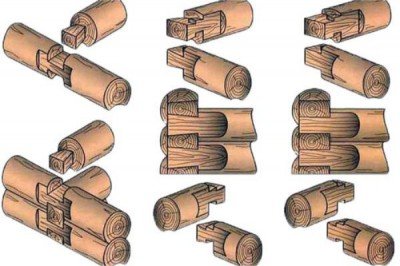

By the way, there are several cuts:

Cut to the “cloud” or “into the bowl” – the most durable

– in “round” (“into the bowl”) – the most common, has three subspecies. One of the subspecies, when the bowl is down, protects the logs from decay..

Cut to the “paw” – an economical option

– in the “paw” – saves wood, but is subsequently subject to rot. Therefore, the first method is always preferable.

If the adherence of the joints is insufficient, then lay moss or tow on the lower log.

The erection of walls from logs

Today it is possible to purchase ready-made baths from logs. This bath is the so-called factory production. Fully manufactured. And then disassembled for parts that are packaged and signed. The buyer can independently or with the help of professionals re-assemble such a bath using the attached instructions.

Construction of a mortgage crown for a bath

If you build a bath yourself, then the first step is to complete the mortgage crown.

The first two logs are laid on the foundation parallel to each other from opposite sides of the structure. We make recesses in the form of bowls on them so that the upper logs lay in them. The next two logs are laid perpendicularly first in the finished grooves-bowls.

The top logs should rise above the bottom only half their thickness.

The walls of the bath from logs are erected according to the algorithm

The second crown is also performed. Bowls are cut out on the lower logs, the following logs are laid on them. According to this algorithm, all bath crowns are performed.

After the construction of the walls, they should dry well. Only after the wood has dried up can we begin to caulk the cracks outside and inside. The material for the hemp is moss, linen tow, woolen felt or modern tape insulation from jute. You need to start from the bottom up, paying particular attention to the corners. At the end of the construction of the bathhouse, a furnace is built from the logs inside, communications are carried out, the roof is mounted, and the premises are finished and filled with furniture.

Baths from a log: photo options

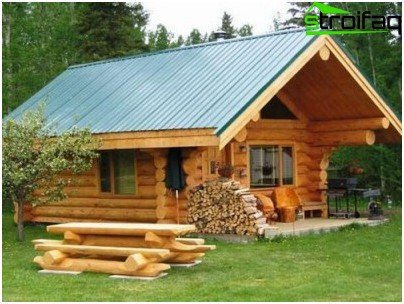

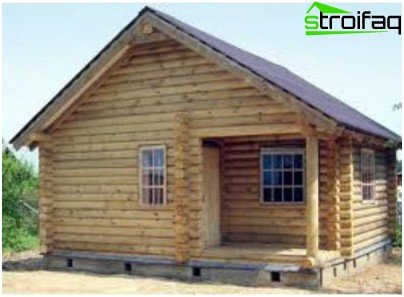

One-story bathhouse made of logs

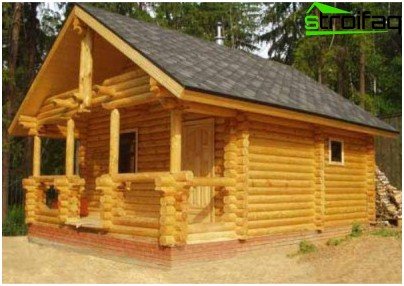

Bath with a wooden veranda – nice to sit after a steam room

A sauna with a terrace allows you to invite many friends

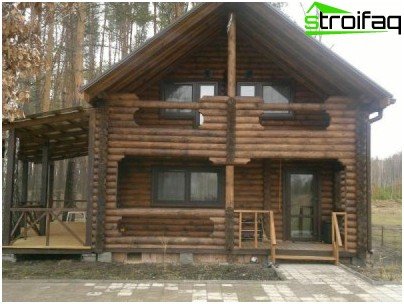

A bathhouse with an attic, a veranda and a terrace is a dream, not a bathhouse

A small log bath – an economical option to build a log bath