Do-it-yourself bathhouse

Currently, you can build a bathhouse from various building materials offered on the modern market. The main criteria that influence the choice are your own preferences, financial capabilities and experience with this or that material. Own bath can become the embodiment of your design decisions. The traditional Russian bath is made only of wood – logs, timber or logs, embodying all the advantages of a natural material. The simplest construction technology is characterized by a beam bath, which combines the natural aroma of wood and clubs of steam, allowing you to relax after working days..

Content

- The advantages of bath buildings made of timber

- How to choose a place for construction

- The choice of material, signs of marriage

- Construction of a bath from a bar: stages

- The foundation for a bath of timber

- Laying the first crown of the log house

- Floor and wall construction

- The device of door and window openings

- The final stage of construction

- Erection of a roof structure

The advantages of bath buildings made of timber

Why do many people choose a beam for construction, and not other materials?

- Firstly, the bar is an environmentally friendly and safe material that does not contain harmful impurities;

- Secondly, building a sauna from a beam with your own hands does not take much time and is available to almost anyone who has little experience with material and tools;

- Thirdly, the beam fits well in rows, almost does not shrink, perfectly retains heat.

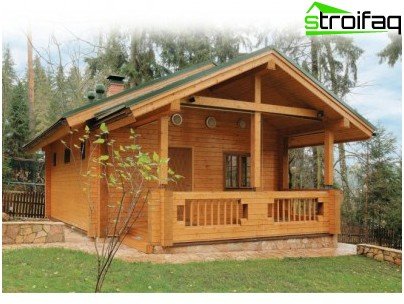

A beam bath can be very aesthetic

It should be noted that the installation of the walls of the bath from the beam is carried out immediately to the foundation, which fundamentally distinguishes this construction technology from the technology of building a bath from logs, for which the logs are first driven on the ground, and only then transferred to the foundation. Another difference of the selected material is that it is easy enough to calculate how much timber is needed in the bath. Timber is a convenient material that does not require the help of specialists in laying, so the construction of saunas from timber can be considered economically viable.

How to choose a place for construction

The correct choice of a place for a bath from a bar is an important point in the initial stage of construction. It is greatly influenced by many factors, which include the type of soil, terrain features, the presence of sewage and water supply, the presence of a drainage system, and the location of nearby buildings. The bath should be located on a site with a natural one-sided slope, which makes it possible to achieve a good outflow of discharged water. Naturally, from the side of the slope there should not be any structures and structures.

If it is possible to locate a bathhouse from a beam close to an artificial reservoir in the area, then you should definitely use it. After the steam room, you can enjoy swimming in the cool water of the pond with great pleasure..

Be sure to pay attention to the fact that the wastewater of the future bath does not cause inconvenience to residents of houses or cottages located in neighboring areas.

The choice of material, signs of marriage

When choosing the material from which a bathhouse will be built with timber with your own hands, it is important to pay attention to its quality characteristics and the presence of defects. Wood should be well processed and prepared. The beam chosen for construction should be smooth and even, otherwise, when laying crowns, it is possible that undesirable problems could occur that could delay the construction time. Only with high-quality material can good performance be achieved..

To operation of the bath was long and trouble-free, before starting construction work, it is necessary to discard the bad and damaged timber. Consider the main points that should be considered when choosing a quality material from which erected timber baths:

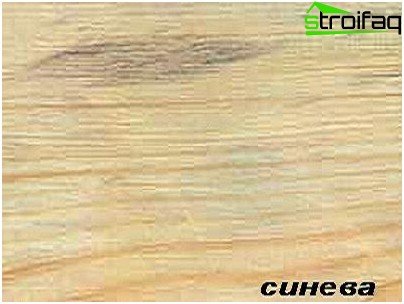

- On the surface of the beam and its ends there should be no noticeable signs of decay, manifested in the form of blue;

The appearance of signs of decay on the timber (blue)

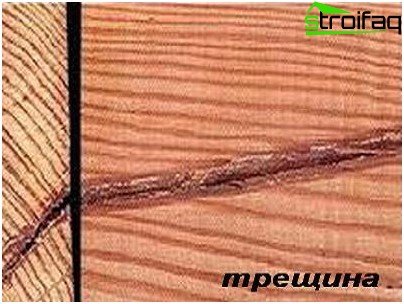

- The material should not contain deep cracks. A beam with cracks up to half the thickness should not be taken into work;

Deep crack in the beam

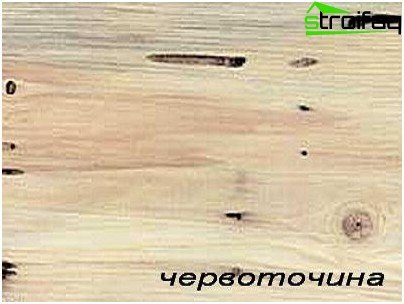

- The surface of the timber should not be damaged by pests. In the presence of traces of damage by bugs (wormholes) going to the core of the timber, such material is subject to rejection.

Damage to timber by pests

The undamaged sections of the rejected timber should be used to create small elements, such as window and door frames, wooden arbor, slats, floorboards and others.

It is important! Of course, if the material has traces of putrefactive formations or bugs, then it is better not to use it so as not to jeopardize the risk of infection with high-quality building material.

If you pay attention to the choice of tree species, then you need to adhere to the following recommendations. The lower crowns should be folded from larch, and the rest – from wood of other conifers. Larch is characterized by the preservation of its properties under the influence of a humid environment, less decay and a higher level of hydro and thermal insulation.

Construction of a bath from a bar: stages

The foundation for a bath of timber

When laying the foundation for the bath, a columnar or tape method is used. Each of them has its own characteristics that have a decisive role in choosing a specific method. In a situation where the bath is being built on rocky or clay soil, characterized by a sufficient depth of groundwater, it is recommended to use the columnar method of laying the foundation. If the groundwater is close to the surface or the ground is soft, then the tape method will be the best option..

The pillar foundation is laid in the traditional way. Brick pillars are set up around the perimeter, corners and at the points of the internal load-bearing walls, usually at a 1.5-meter interval. In some cases, an increase in the gap between the supporting posts up to two meters is allowed. When installing the foundation in this way, a concrete “pillow” should be poured under each pillar.

Column foundation for a timber bath – an economical, quickly implemented solution

The strip foundation is characterized by the formwork device, after which the surface is poured with concrete to the level of freezing of the soil. It is necessary to ensure the height of this foundation is not lower than 50 cm above the ground, which will protect the lower crowns from exposure to excess moisture. Beginning of laying the first crowns of the log house is possible after the final hardening of concrete, in about 2-3 weeks.

The option with a strip foundation will require delaying the erection of walls until the cement has completely hardened

Any of ways requires strengthening the foundation reinforcement, which increases the strength of the entire structure and creates a reliable mount for the lower corners of the log house.

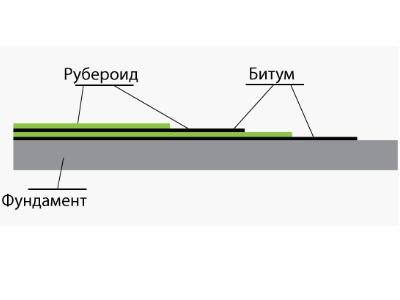

Long-term operation is possible only with properly organized waterproofing of the bath from the beam – a photo schematically illustrating the implementation of this event allows you to make a more complete picture. Between the basement of the foundation of the bath and the lower crown, it is mandatory to lay waterproofing material in two layers. Molten bitumen is applied to the surface of the foundation, and then completely covered with roofing material. The process is repeated after the first layer of bitumen has dried..

Laying the first crown of the log house

The stage of laying the crown starts with the installation of thin wooden battens, pre-treated with an antiseptic, on the entire surface of the basement base. This layer provides additional protection of the first rows of timber from moisture. The space between the rails is filled with insulation or polyurethane foam. At this stage, the horizontal evenness of the surface is carefully checked using the level.

Thermal insulation of the foundation will reduce heat loss

The first row is made of a thicker beam, since it must support the weight of the entire structure. Most often, a beam with a cross section of 200×200 mm is used for a mortgage crown, for 150×150 mm for the following crowns. Felling is not carried out very tightly, as the material will slightly shrink and compact. The lower crown, which is laid on the foundation, is not fixed, since the heaviness of the upper rows provides the necessary strength.

The beam is carefully adjusted in length, after which cuttings are made at the ends. The performance of these works requires special accuracy and accuracy. The joining of the beams of the lower crown is carried out after checking that all the necessary parameters are observed, the formed space between the beam and the foundation should be filled with insulation.

The mortgage crown of the log house of the bath is subjected to antiseptic treatment, special attention is paid to the place of its adjoining to the foundation.

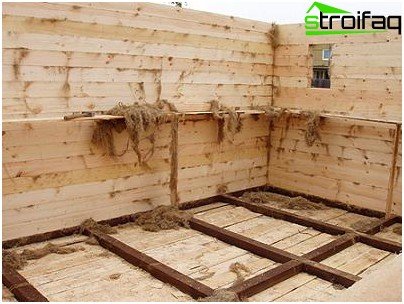

Floor and wall construction

When assembling the floor, it should be noted that to remove water from the surface, you need to make a slight slope of 3-4 degrees. At this stage, lags are installed on the foundation, on which floorboards are then mounted.

Insulation between the crowns

The walls of the timber bath are folded in a certain order. The crowns are carefully aligned horizontally, fastened together with metal pins or wooden pins. Fasteners are driven into special discharge openings, which must correspond to the diameter of the fastening pins.

Between the bars for insulation, a heater is laid (for example, tow, jute, moss). The height of the walls should not be too large, since a large area will be more difficult to heat..

The device of door and window openings

After the construction of the walls and floor, they begin to install door and window frames. In places intended for windows and doors, small gaps are left when laying walls of timber. After shrinkage of the log house, in the planned places, openings are cut that correspond to the parameters of the door and window frames.

Future window opening

Doorway opening

The final stage of construction

The final stage in the construction of a bath from a bar is considered to be the preparation of a log house for shrinkage, which lasts at least six months. After preparing the log house, a row of boards are laid on the upper crowns, which are completely covered with slate or roofing material. After a set period of time, they complete the finishing work and make the final improvement of the bath.

Erection of a roof structure

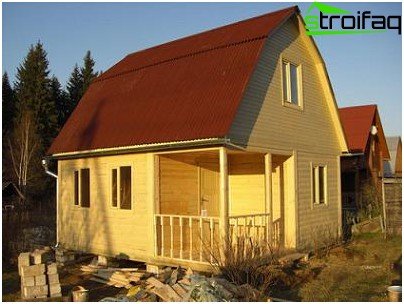

The roof for the bath is either single or double. The first type is well suited for a small bath, it has a cheaper manufacturing cost. Roofs of the second type are characterized by a more complex structure, which is successfully used for larger structures, for example, for a bath from a bar with an attic.

Recent trends in the construction of baths from timber

Two-story sauna from a bar: in the spacious attic you can arrange a relaxation room or a small gym

Recently, two-storey timber baths have been in special demand, combining the functions of a traditional bathhouse and a living room. And finally, how a modern sauna from a bar looks from the inside – photo of the interiors.

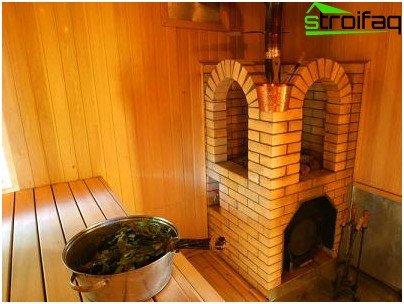

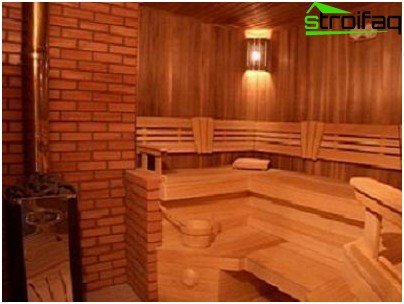

In the interior decoration of the bath, according to tradition, wood predominates, perfectly harmonizing with a brick stove

Bench and shelves in the interior of the bath of timber

Variant of a modern interior in a timber bath: a pleasant atmosphere conducive to the adoption of bath procedures