Do-it-yourself brick building

Each owner wants to build a bathhouse on his summer cottage or on the personal territory of a country cottage, because no modern showers, bathtubs, jacuzzi can replace the healing effect of a Russian steam room. As a building material, wood, brick, foam blocks are used. A brick built bath is inferior to a similar wooden structure in thermal conductivity, but wins in terms of durability and fire safety. To reduce the cost of purchasing bricks, special masonry methods are used, providing for the presence of voids in the wall, which are filled with cheaper building materials. At the same time, the heat engineering indicators of the entire structure increase.

Content

- Brick Brick Design Selection

- Strip foundation device

- Performing the work in steps

Brick Brick Design Selection

At the initial stage, a site is selected for the construction of the object. Based on its size and preferences of family members in terms of the dimensions of the future structure, the final design of the brick bath is approved. This document should contain detailed drawings indicating the exact dimensions of all main walls and internal partitions. Ideally, project documentation should be ordered from specialists, but you can use ready-made projects posted on the Internet or borrowed from friends. In a carefully designed project, all necessary building materials should be provided, which go both to the construction of the brick bath itself, and to all types of its internal decoration and external decoration.

Brick bath project

Important! Brick bath projects pay great attention to thermal insulation in order to minimize possible heat loss. At the same time, not only walls are insulated, but also the ceiling, floor, window and door openings.

Strip foundation device

The construction of a brick bath requires a reliable foundation foundation for all supporting structures. So that cracks do not go along the walls, they lay the strip foundation, which is able to withstand their weight.

The materials used are solid red brick, rubble stone, slag concrete or concrete blocks. In the presence of sufficient financial resources, it is possible to fill in a monolithic reinforced concrete foundation.

Important! When laying the foundation, do not forget about the depth of freezing of the soil in your area. The depth of the dug trench will depend on this indicator. When calculating the width of the foundation, they are repelled from the thickness of the walls, adding a couple of tens of centimeters to this value.

Performing the work in steps

- A layer of sand is poured onto the tamped bottom of the dug trench, the thickness of which should be at least 15 cm. The sand layer is shed with water and carefully tamped..

- Next, a crushed stone layer is laid, the thickness of which should be the same. Also carry out its ramming.

- After preparing the sand and gravel base, rubble stones are laid and poured with concrete mixture.

- After the concrete has dried, a waterproofing layer of roofing material is laid..

- Next, a base is being built, for which a solid red brick is already being used. The height of the basement is 4-5 bricks. At the same time, one does not forget to make ventilation holes in one of the brick rows -.

Brick building

Masonry Methods

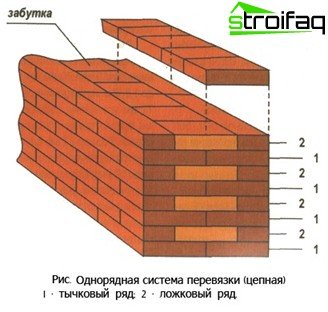

Erected do-it-yourself bath of brick can in several ways of masonry. At the same time, they resort to the use of a single-row or multi-row dressing system. Most often, the first of them is preferred, since it is notable for its simplicity of execution, but at the same time it is quite durable. An important argument in favor of choosing brickwork according to a single-row dressing system is the insignificant wall thickness of this object.

Single row brickwork

Brick rows depending on the location of their individual elements (bricks) can be:

- spoon (bricks lie along the wall);

- poking (bricks are laid across the wall).

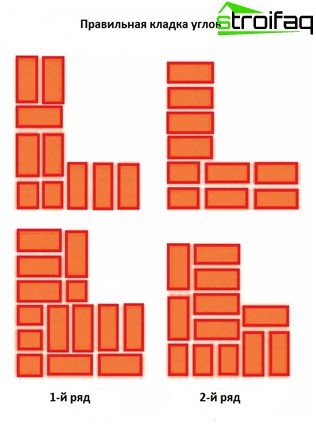

The alternation of these types of rows underlies the single-row dressing system. At the same time, it is possible to block the vertical seams of the previous row with the bricks of the next. The quality of such brickwork depends on the correct arrangement of corners and piers, which begin to spread with three-quarters of brick. The technology for laying corners also provides for the need to lay out one side with “spoons” and the other with “pokes”.

Multi-row brickwork

In some cases, for the erection of the walls of the baths, a well masonry is chosen, which implies the placement of an insulating backfill from such bulk materials as fine slag, sand mixed with sawdust, expanded clay. The laying of walls in this embodiment provides for the presence of transverse walls located every three bricks. The voids are filled immediately as the walls grow, and the filler is compacted every 10-15 cm. At the same time, every third layer is poured with a solution of lime having a creamy consistency.

In the course of work, bricks appear, broken or having any other defect, which are used for laying piers and corners. For the same purposes, halves, three-quarters or quarters of bricks are used. To get the right size, the brick is chopped with a pickaxe.

Important! To avoid a large amount of brick waste, it is necessary to calculate the length and width of the walls for the size of the material selected for the construction of the bath. The indicated values should be divided without residue by 75 mm if a brick of 24x12x65 mm is selected, and by 100 mm when using a brick of 24x12x88 mm.

The specifics of the construction of corners

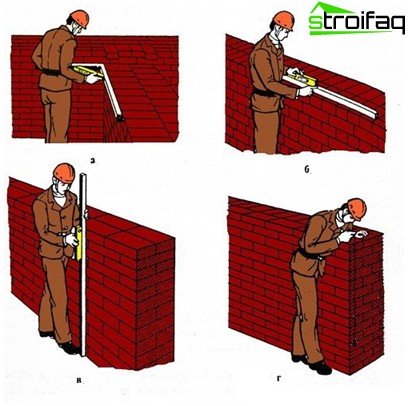

A brick bath begins to be built with laying corners, which are connected by a mooring cord, which serves as a guide for laying a number of bricks. Using a mooring cord allows you to ensure the horizontal and straightness of the rows of masonry, as well as the same thickness of all horizontally applied seams. To comply with the right angle, use a construction square, level, as well as the rule.

Brick masonry corner laying

Masonry solid brick walls

For quick bricklaying, you need to have a skill that comes only with experience. In order for the constructed brick bath to be strong with its own hands, it is necessary to properly prepare the solution used to fasten the bricks. At the same time, it must not be allowed to prematurely harden, therefore, its surface of the previous row is laid out with a thin layer (20-25 mm) and at a distance of no more than a meter.

This will reduce the waste solution and reduce the work on the alignment, which is carried out using a trowel. In this case, the builder must monitor the quality of the resulting joints, paying attention to their thickness and uniformity of compaction, filling with mortar and correct dressing.

Masonry brick walls

Masonry over window and door openings

Over openings of windows and doors, you must make jumpers. During the construction of the baths, the simplest ordinary jumper is used. It is ideal for covering spans less than two meters wide. When laying out ordinary jumpers, observe the horizontality of the rows and all the dressing rules applicable for ordinary masonry. The height of the jumpers reaches 6-9 rows of masonry, and the length should be half a meter more than the width of the opening. For laying out the jumpers, only selective brick is used, which is placed on the solution of the brand at least 25.

The jumper device involves the use of formwork from boards, the thickness of which is 40-50 mm. With the direct installation of window and door frames in the walls, they can be used as formwork. However, the wooden elements are protected with a layer of roofing material. A 20 mm layer of cement mortar is applied to the formwork before laying the ordinary lintel, into which the reinforcement in the form of metal rods with a diameter of 4-6 mm is recessed. The ends of the reinforcement must extend beyond the edges of the opening by more than 25 cm, while its ends are bent around the brick. Withstand an ordinary jumper on the formwork, depending on the air temperature from 12 to 24 days.

Finishing the brick walls of the bath

Brick walls are finished using plaster. To do this, a metal mesh is attached to their wall surface, which holds the applied sand-cement mixture. When sheathing the inner walls of the bath with a clapboard, plastering work is skipped. Metal profiles or wooden slats are fixed to the walls with dowels or nails, which are driven into wooden corks pre-mounted in the walls. Between the lining and the wall, the thermal insulation is laid in a visible foil or tile material. In the case of choosing horizontal boards for wall decoration, bulk expanded clay can be used as insulation.

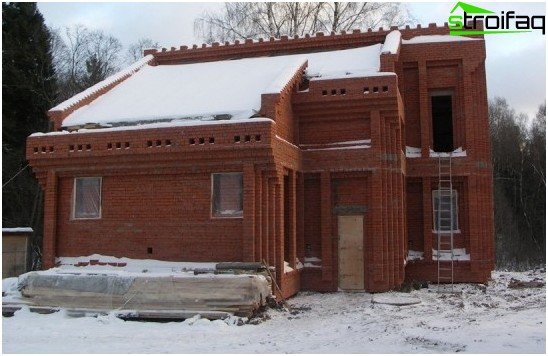

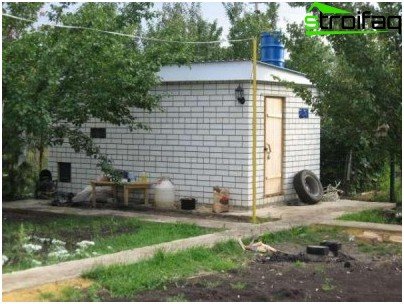

Brick baths: photo selection

Brick bath

Brick bath

A simple version of a brick bath

The construction of a brick bath requires training. Therefore, even when erecting an object with your own hands, you need to hire a competent specialist as an assistant who knows the intricacies of working with bricks and other materials. In this case, it will be possible to save on attracting a team of builders and at the same time achieve the quality of all necessary work.