How to make a ceiling in the bath

The maintenance of the required room temperature, as well as the service life of the building, largely depends on how well the ceiling in the bath is arranged. Even its height plays an important role: for better warming, it is enough that there is a space between the ceiling and the highest shelf, allowing a person to sit quietly in a bath cap. Despite the complexity of the task, you can cope with the installation of the ceiling yourself, most importantly, determine the type of ceiling and the type of materials used, as well as follow some simple tips outlined in our article.

Content

- Landmarks for the ceiling in the bathhouse

- Types of bath ceilings

- The specifics of the lay option

- Features of the panel ceiling

- Phased device description

Landmarks for the ceiling in the bathhouse

When installing a ceiling in a bathhouse, builders must face a number of issues:

- what type of ceiling will be installed;

- what will be the height of the ceiling in the bath;

- what material will be used during installation.

As already mentioned above, such a height will be optimal that, sitting on the very top shelf, not reach your head to the ceiling, but at the same time it should not be less than 2 meters. It is best to use carefully dried wood when working. Coniferous boards are most suitable for this purpose, but deciduous, for example, linden or aspen, are preferable for internal lining. Board constructions, due to their tight fit, are characterized by good heat retention, but when choosing them, special attention should be paid to the resin content. Low resin wood has low thermal conductivity, high temperature resistance and good sound insulation..

The device of the ceiling of the bath includes heat and vapor barrier. A dense film will be a good vapor barrier, and basalt fiber coated with a layer of foil can be used as a heat insulator.

Tip: for thermal insulation, you can apply such accessible materials as earth, clay, sawdust or shavings.

Types of bath ceilings

There are three types of ceilings for a bathhouse:

- grazing;

- panel;

- filed.

The specifics of the lay option

In small baths, the span of which does not exceed 2.5 meters, it is recommended that such a ceiling device in the bath. This option is also suitable for buildings with a solid wall in place of a conventional shield partition..

Boards in flooring are placed joint to joint, as tight as possible

Boards with a thickness of not more than 50 mm are laid directly on the walls of the bath, butt to butt. Steam and heat-insulating layers spread over the resulting shield. As a vapor barrier, you can use foil, roofing felt or roofing. Then a soft insulation crumbles, for example, peat, which is closed with a crochet attached by nails to the beam.

Tip: instead of slab or slate, you can use independently made fire-resistant slabs (dimensions: beam pitch x 300 mm x 20 mm), which are poured out of a solution consisting of four parts of clay, 0.3 parts of cement, one part of sawdust and two parts of water.

Important: when using bulk materials as insulation, it is necessary to raise the protective sides along the entire perimeter of the attic. This will help to prevent the layer from spilling from the ceiling..

A significant disadvantage of this method is the inability to use the attic space to move around it. This can lead to a violation of the insulating properties of the structure and general damage to the ceiling. Such an attic can be used only for drying brooms and bath accessories. You will have to face big problems when repairing floors or a rafter system, because in this case movement on the ceiling cannot be avoided, and, consequently, damage to it cannot be avoided. But the floor ceilings are easy to install and their low cost..

Features of the panel ceiling

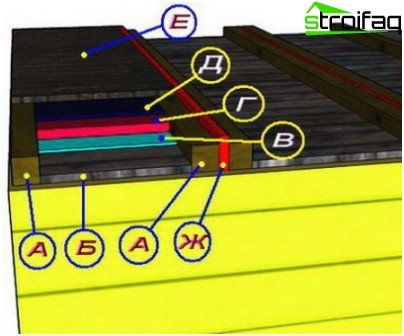

The panel ceiling is mounted from pre-prepared panels of a special design, consisting of:

- two bearing bars;

- inner lining;

- steam, heat and waterproofing;

- external ladder located only from the attic side.

A – bearing bars; B – inner lining; B – vapor barrier; G – thermal insulation; D – waterproofing; E – external gangway

That is, the insulating layers are placed, as it were, in a “trough”, which is closed from above with a wooden flooring. As a rule, such shields turn out to be rather heavy, which not only complicates the installation, but also unnecessarily burdens the ceiling of the bath. In order to at least slightly lighten its weight, it is recommended to use basalt fiber or glass wool laid with a layer of not more than 100 mm as a heater.

Shields are tightly stacked to each other, and between them is placed an elastic gasket of waterproof insulation material. This is to prevent heat loss through the inter-panel slots. Felt with polyethylene or foil gasket is very suitable for this purpose..

The main advantage of a panel ceiling is its efficiency. Indeed, for the manufacture of panel boxes, you can use the scraps of lumber remaining during the construction of the bath.

But the disadvantages include the large weight of the finished shields. If any other ceiling of the bath can be done by one person with their own hands, then panel overlap requires the participation of several builders. More experienced people first install empty boxes, and then, already in place, fill them with insulating layers and cover them with an attic flooring.

Tip: during the operation of the bath room, water may accumulate on the upper ceiling lining. To avoid this, the ceiling should be upholstered with a slight slope of approximately 5 °.

Phased device description

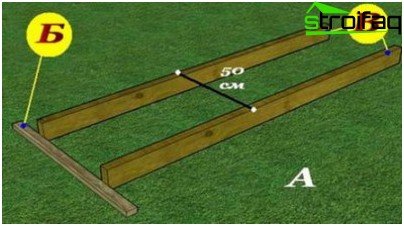

So, how to make a ceiling in a bath from panel panels? The device of such a ceiling begins with the assembly of structural elements. Two bars of the panel are stacked at a distance of 500 mm from each other, while their ends should be abutted in a flat rail, pre-laid on the site.

Two bars are installed at a distance of 50 cm from each other and are aligned along the rail

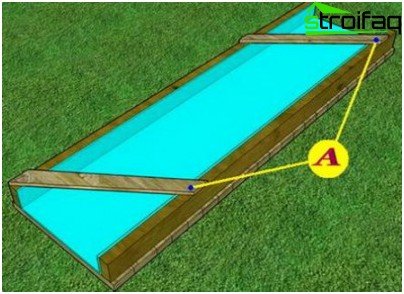

600 mm long boards are attached on top using self-tapping screws or ordinary nails, so that a protrusion equal to 50 mm is obtained on both sides. This gap is necessary for the subsequent placement of steam and heat-insulating material between the boards.

After all the boards are attached, the panel is turned over and a vapor barrier is attached to it using a stapler or thin rails. To move the shield to the bath, the bars must be fastened together with two slats obliquely, this will help to avoid distortion of the structure during transportation. Subsequently, these jibs are removed.

Before moving the panel panels, it is necessary to fasten the supporting bars to each other with oblique rails.

Before installing the panels on the walls, a sealant, such as jute, must be placed under them. After placing all the boards on the vapor barrier, thermal insulation is laid and then waterproofing.

Important: the panels are interconnected only with the help of boards, in no case can you use a screed or fastening to the upper beam of the log house.

The insulation is laid at the junction of the panels with each other. Sheathed ceiling of shields as follows:

- A solid board with a length equal to the width of all stacked panels is fastened with screws to their bars.

- Then several short boards are attached to them, and then again a solid board.

- Joints of short boards are closed by means of an overhead rail.

Hemp Priorities

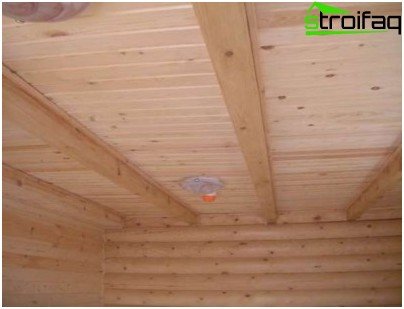

The false ceiling is a covering of ceiling beams with a lining. Further, insulating layers are laid on the boards, that is, steam, heat and waterproofing, and in this order. After the location of the waterproofing, the ceiling is completely sheathed with boards from the attic.

False ceiling is made of lining or trim board

This type of flooring is ideal for building a bathhouse with an attic, since all insulation layers are reliably protected on both sides by a plank flooring. It is easily mounted independently by one person, but it is expensive because it is necessary to purchase massive beams and solid boards for lining spans.

False ceiling device

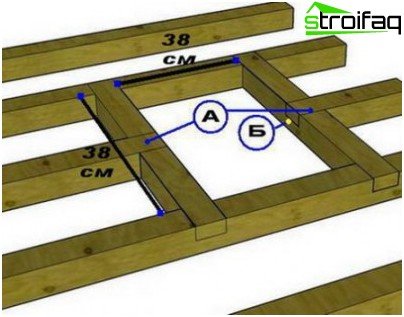

Before proceeding with the installation of this type of ceiling, it is necessary to prepare a sufficient number of edged boards (lining). First, beams are laid, and then a hole for the chimney is formed. To do this, grooves are made in the cross-pieces in the center into which the central floor beam is placed. We fix the entire structure with nails. Typically, the opening for the chimney has dimensions 380×380 mm.

For the installation of the chimney, it is necessary to perform the grooves (A) in the cross members and install the central floor beam (B) in them

Now you can proceed with the installation of the ceiling panel. To do this, the vapor barrier layer is attached to the floor beams using a stapler, and before that all the ends are treated with a special antiseptic. We lay the material so that it has a lap on the walls of at least 150 mm.

Next, we take one edged board and with the help of a planer we plan the spike for a tight fit to the wall of the bath. Now we place the next board with a spike in the groove of the first board and connect them tightly, gently tapping with a mallet along its entire length. Similarly, the whole ceiling is going.

After the shield is assembled on the vapor barrier, insulation is laid out, and then waterproofing, which is covered with a deck of boards attached to the floor beams using long nails.

Tip: it is better to choose nails for mounting the ceiling in the baths with a wide hat and always galvanized. Their length should be at least two times the thickness of the attached board. Instead of nails, you can use screws of the same length.

So, before you make the ceiling in the bath, you need to decide on the choice of its type. Each design has its own advantages and disadvantages, but most often in the baths, hem and panel ceilings are used. Panel ceilings are difficult to install, and it is this fact that usually plays a decisive role in the selection. In addition, the false ceiling is characterized by durability and increased strength..