How to caulk a log house

Now houses and saunas from a log house have become increasingly popular. The secret of such success is simple – wood is an ideal heat-insulating material, and the log building looks unusual and very respectable. And with the return of fashion to all-natural, the ratings of log cabins generally reached unprecedented heights. But even such a warm and reliable material as a log needs to be insulated, so many owners of such real estate have a reasonable question: “How to caulk a log house?” Let’s take a look at this “bone-in” topic..

Content

- Why do you need to caulk a log house?

- Modern caulking materials

- Jute – the most popular option

- Flax

Why do you need to caulk a log house?

The caulking of the log house is a very important stage of construction, the neglect of which can significantly impair the thermal insulation of the building. The thing is that when laying the logs between them, voids and gaps form, which must be “destroyed” in some way.

In addition, the log cabin will settle over time, which will necessarily cause the appearance of new cracks. Through them, that warm home air will “run away” to the street. It’s okay even in the summer, but in winter the consequences can be much sadder – the heated air when it enters the cold atmosphere instantly turns into hoarfrost, which settles on the logs. And as you know, hoarfrost always carries with it problems associated with humidity and dampness, which, in turn, will cause decay..

Modern caulking materials

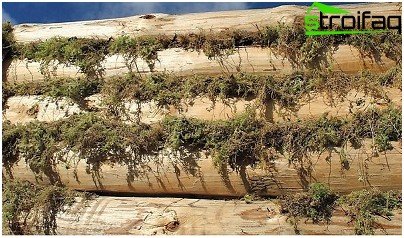

In ancient Russia, hemp, moss sphagnum and felt were used for caulking.

Today, these materials are also in demand, however, increasingly for primary insulation.

So in the old days they insulated houses. Moss-sphagnum – funny and ridiculous, but effective

Jute – the most popular option

Jute is a natural insulation of plant origin, which “comes” to Russia from Kazakhstan, China and India. The fiber of this plant is appreciated for its strength, high spinning qualities and low hygroscopicity..

Jute fiber is delivered predominantly in the form of a special tape with uniform density and equal width.

Very often, manufacturers impose jute felt on the buyer, citing the fact that he has exactly the same characteristics as pure jute. However, this is not true. Such material is much more prone to getting wet, which means that it will begin to rot much faster. In addition, it has low strength indicators, which affects its heat-insulating properties, and the mole simply adores it.

Flax

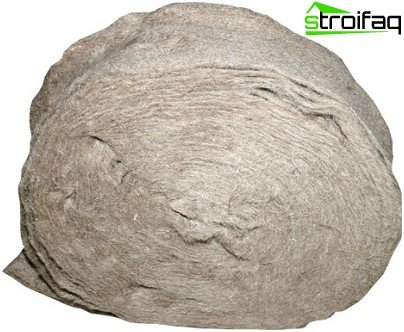

Flax flax is obtained from flaxseed waste. It comes in the form of a long ribbon twisted into a roll. This material consists of fine flax dust, which has a short fiber structure. The density of such a heater is not less than that of jute, but its structure is much more elastic and stiff.

Roll of flax, before laying the material will need to be cut

Types of caulking

There are two types of caulking: “stretching” or “knitting”.

Method of caulking “stretch”

This caulking method is used if the gaps between the logs are narrow and almost invisible.

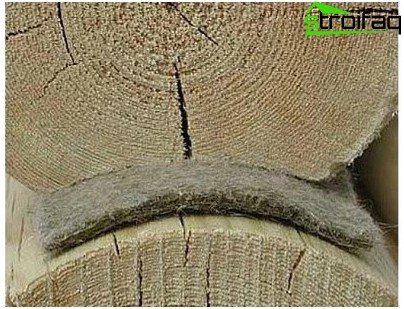

During work in this way, a strand is formed from the insulation, which is placed in the slot across the fibers, and then gently push it inside with a spatula, but the edge of the material (4-5 cm) should remain outside. Next, a thin roller is made from tow, which is then wrapped in the remaining free edge of the insulating material. It remains only to hammer this roll with a chisel.

The process of driving flax in the slit of the log house

Method of caulking

This method is advisable to use when the cracks and voids between the logs are wide and deep.

For a caulking house of a log house the long thin ropes, which are wound into a ball, are twisted from tow to a set. Then, gradually unwinding it, the tow is hammered into the cracks using a caulking chisel. Since the dimensions of the slots are different everywhere, you will have to gain the required thickness of the rope by turning it or simply twisting the loops.

And first, the insulation is clogged in the upper part of the gap, and then in the bottom. To make the seam look more or less “decent” and even, at the end it can be sealed with a special tool – a road builder.

Important: loosely clogged tourniquet will soon be pulled by birds, so treat this stage of the caulking process with all responsibility.

Caulking

Secrets and subtleties of caulking

There are many nuances in the caulking affair, however, you should not be scared of this, because, as they say: “Eyes are afraid, but hands do”.

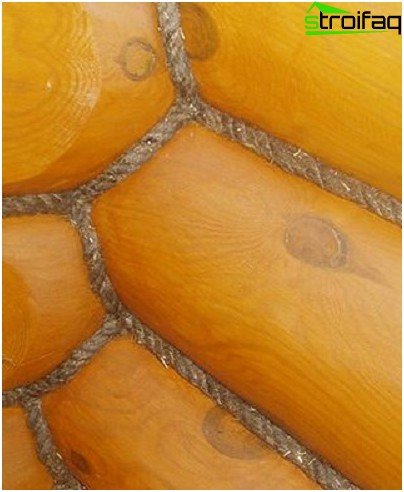

- firstly, the first stage of caulking begins during the laying of logs. It is then that a layer of heat-insulating material is placed on each log. If it is flax or jute, then it is fixed with a construction stapler, but it should be noted that the insulation should protrude from the grooves by about 4-5 cm on both sides of the log house.

Securing the insulation with a stapler

Here is the insulation laid under a log

- secondly, to qualitatively caulk a log house, you will have to carry out at least two caulking procedures. The first – immediately after the assembly of the log house, and the second – after about one year, it is then that the insulation will partially shrink and some of the cracks will again become visible. Five years later, when the log house has completely settled down, caulking can be repeated again to finally fix the effect of thermal insulation.

- thirdly, for a greater effect, caulking must be done on both sides of the log house, that is, on the external and internal.

Important: the caulking process leads to a slight raising of the log house, which sometimes can be 6-7 cm. Therefore, it is important to carry out the procedure before the final finishing work.

- fourthly, all work related to caulking should be carried out strictly along the perimeter of the log house from bottom to top, since when laying insulation, the height of the log house increases, as mentioned above. If you caulk each wall individually, then most likely, in the end you will get a building in the style of “at random”.

Important: the log house should be caulked in strict sequence: first, the external cracks are clogged around the entire perimeter of the lower rim, then we go inside the house and do the same job. Then again we go to the street and caulk the cracks of the second crown, after that we return to the house, etc. If you neglect this recommendation and carry out work first on the street. and then inside the building, then the walls will deviate vertically.

Well, now you know how to properly caulk a blockhouse and do not make mistakes that can lead to sad consequences. Warm yourself according to the rules, and then your home will always be cozy and welcoming.