Warming and thermal insulation of the bath

Vigorous steam and healing heat are the advantages of a well-insulated bath, which performs hygienic and healing functions at the same time. Competently made comprehensive thermal insulation of the bathhouse, thorough observance of technology and the correct selection of insulation for all building structures will help to create and maintain the advantages of bath houses. Good insulation, working on the principle of a thermos, will provide the conditions required for the adoption of hygiene procedures, will form a “healthy” atmosphere. An important argument in favor of warming bath rooms is to extend the life of the building and bath equipment, as well as reduce fuel consumption.

Content

- Requirements for thermal insulation of the bath

- The ideal result is symbiosis

Almost all types of existing building materials are used to build a bathhouse on a suburban area. Baths are built from timber, foam concrete blocks, prefabricated prefabricated frame structures, bricks, logs. A lot of variety in the projects of bath facilities. Responsible owners are now not enough standard three branches, which include:

- washing room,

- steam room,

- comfortable lounge.

Often, owners of suburban land tend to erect on their territory a real bath complex with shower, billiard room, bedroom on the second floor, to equip a Russian steam or Scandinavian sauna. Naturally, in each case, the warming of the bath is carried out according to a special scheme, focused on the specifics of the operation of the building, the area, number of storeys and the number of rooms, as well as on the material selected for construction.

A presentable two-story bath with many functional rooms will be able to replace a country house in a suburban area

Requirements for thermal insulation of the bath

The special operating conditions of the bath houses determine the set of requirements for insulation material.

The insulation selected to optimize the insulation qualities of the bath should:

- work well in conjunction with building and finishing material, increasing thermal performance, do not affect their specific advantages;

- differ in stable strength, not decreasing from temperature changes, from the excess of fumes, from exposure to high temperature;

- to prevent the formation and accumulation of condensate, the occurrence of destructive factors of biological origin;

- have minimal moisture absorption and high insulating parameters;

- have certificates confirming the safety of use according to sanitary-hygienic and fire criteria;

- do not emit toxic substances under conditions of high-temperature operation;

- provide ease of installation and the ability to perform thermal insulation of the entire structure without gaps and gaps that increase heat loss.

The ideal result is symbiosis

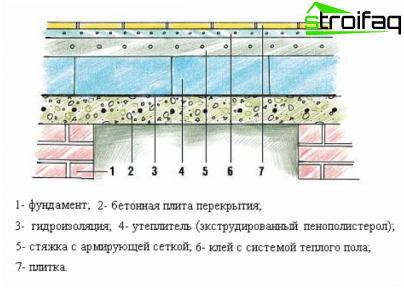

Effective insulation of the bathhouse involves the use of several heat-insulating materials. They are used to equip walls, roofs, floors, ceilings, and perform internal and external thermal insulation. Many owners decide to equip the bath with a “warm floor” system, which requires the use of special insulation. A number of combustible insulating materials is incompatible with wooden rafter structures and wooden walls, but it works perfectly in conjunction with foam concrete blocks or bricks. In general: to equip a bath with a good energy-saving layer, it will require the use of several types of heat-insulating products and the use of different technologies.

The layout of the bath floor with a polystyrene foam insulation

Range of materials for insulation

Insulators for baths supplied by manufacturers to the market have a different state of aggregation. Amorphous fillings, which are granules of different sizes, light extrusion products, small blocks, randomly located or strictly directed fibers connected to a fabric-like material, can take part in the arrangement of the bathhouse structure. In the process of insulation, special mats, plates with increased rigidity, rolled material are used. There is even a liquid insulation for the bath, which after applying and drying the suspension turns into a polymer elastic coating.

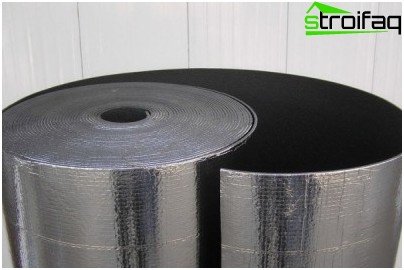

Often, aluminum foil is used to warm the bath rooms, which simultaneously performs the function of a thermal energy reflector along with insulation. It is suitable for the steam room and for the washing compartment. Protective structures and a heat-insulating layer can serve as a plastic film, kraft paper, which can only be used in the arrangement of facilities for recreation. To protect wooden structures, a kind of “folk” mixture is suitable, consisting of sawdust with a clay binder. You can purchase a special finished composition with similar properties.

Note. Roofing material or roofing material that emit harmful toxic components when heated is not recommended for interior design.

Metal foil – a heater combining the functions of a heater and a reflector of thermal energy

The assortment of thermal insulation materials includes heaters of organic, mineral and artificial origin. Each of them has positive qualities and negative sides..

Heaters of natural origin

For many centuries, baths in Russian villages were insulated with moss, hemp, hemp, linen tow, woolen felt. The materials providing excellent natural air exchange are still preferred by many now. Construction red moss, used for caulking of joints between crowns, does not rot, contains bactericidal substances. The same qualities are possessed by cuckoo flax and sphagnum moss, added to the composition of tow and flax fiber. Their disadvantages include:

- high price;

- the duration of the insulation work;

- probability of damage by moths, mice, birds.

In order to control pests, this type of cannabis can be treated with chemicals, but environmental priorities in such cases are reduced to zero.

Natural insulation for a bath from a log, caulking for walls will have to be periodically updated, as birds can “pull it off”

Heaters made from flax and jute are resistant to decay. Jute felt, linen batting and a mixed linen jute fabric provide excellent compaction, due to their elasticity they close well the seams, they are affordable. Flax jute products have excellent qualities in which the fragility of jute is balanced by the flexible elasticity of flax. This is an effective insulation for the walls of the bath made of wood, it is suitable for work on the inside and outside of the building. Using these materials, the grooves and gaps of the building are insulated after the construction of the roof structure. Re-caulking is performed after the wood has dried out after about a year.

Organics for warming the bath

Thermal insulation products with a base of organic raw materials are made from peat, waste from woodworking production, and reeds. Wood fiber, peat, particle board, reed slabs are not recommended to be located in the zone of frequent exposure to elevated temperatures. Despite the processing of most types of wood concrete, fiberboard with flame retardants, it is better to equip the locker room and other recreational facilities with their help. For exterior cladding, they are only suitable in regions where there is no frost more than -17 degrees.

Mineral insulation

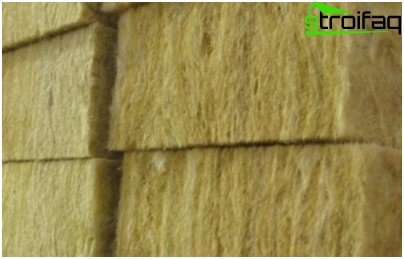

Mineral heaters are considered the most economical and practical. Their cost determines the predominance of this type of insulation in the field of industrial construction. Mineral wool of various composition and mats made of slag or stone fibers are involved in the arrangement of almost all building structures, and can be used to insulate any of the surfaces of bath houses.

Priorities of basalt, diabase, limestone, dolomite and slag wool:

- incombustibility, the ability to prevent the spread of fire;

- high insulating characteristics;

- duration of operational periods;

- lack of noticeable deformation during prolonged use in any conditions of complexity;

- water repellent.

Special mats made of stone wool facilitate the process of insulation, reduce the time of work. In addition to simple and convenient installation, stone and slag material has another significant advantage: rodents will not spoil it. Therefore, any stone and basalt insulation for the bath most often equips the floor and the lower floor, which is also dictated by the weight of the products.

Basalt cotton wool is one of the most popular types of material for thermal insulation of a bath, it is necessary to use it with a waterproofing layer, since when wet, the insulation qualities deteriorate

Technical characteristics and operational advantages of mineral cotton insulation practically coincide with the performance of glass wool. However, a more flexible glass wool is more convenient to install. True, it has a lower limit of resistance to high-temperature effects, but it is unlikely that anyone in the bathhouse will want to test the material at + 450 ° C, and no one will probably steam in such conditions.

Polymer heaters for baths

Lightweight, practical and easy to install, synthetic heat-insulating materials are resistant to moisture and high temperature. Those who wish to make thermal insulation can use three types of insulation materials made on the basis of plastics, these are:

- foams with a cellular and foamy structure;

- cellular plastic heaters;

- poroplasts.

Insulating polymers such as polyurethane foam, extruded or extruded polystyrene foam are distinguished by an excellent combination of low bulk density and high heat-shielding properties. They do not absorb moisture, are characterized by high strength and long-term excellent service. Variants of these products currently presented by industry contain flame retardants as additives. They do not burn, they tend to prevent the spread of fire, they themselves die out when a random spark hits the surface. Non-combustible plastic heaters are suitable for arranging floors, performing external cladding of the bath with insulation.

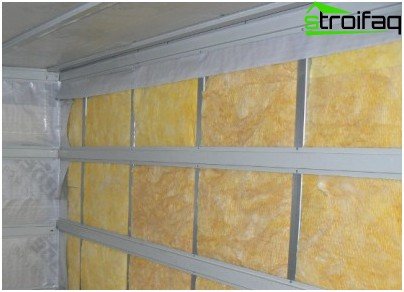

Among the foamy insulating materials, foam glass is not the last place, which embodied the best qualities of stone wool and foam. Durable, non-combustible, waterproof insulation is easy to “cut” with a saw or knife, attached to surfaces. Thermal insulation with polymeric materials should be carried out in conjunction with the mandatory use of a vapor barrier layer, without which condensation can accumulate on the insulation.

Thermal insulation of the walls of the bath coated with vapor barrier material

Thermal insulation baths: stages

All types of work to improve the insulating characteristics of the bathhouse are divided into the performance of internal and external insulation. They begin to equip the surface with a layer of insulation during the construction process. The work is carried out in the following sequence:

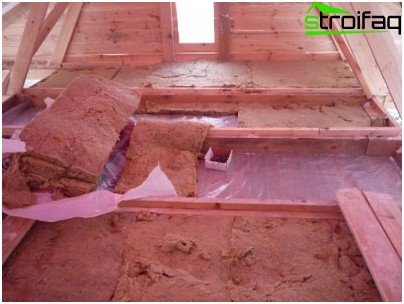

- Thermal insulation of the foundation and floor, for which stone or slag wool, expanded clay or other amorphous insulation material, expanded polystyrene, any kind of synthetic insulation in the form of mats or panels can be used;

- Insulation of the surfaces of load-bearing walls from the inside and partitions. Premises operated in different temperature and humidity conditions are equipped with various types of insulation;

- Insulation of the ceiling surface. Effective insulation for the ceiling of the bath hides from the side of the subsequent cladding with a layer of vapor barrier material. To ensure thermal insulation, there is a large selection of materials equipped on one side with a metal foil that improves insulation performance, insulation strength and has the effect of reflection of heat waves.

- Roof thermal insulation works that predetermine the use of heat and waterproofing materials.

Proper thermal insulation of the ceiling of the bath will protect from condensation, extend the operational life of the bathhouse

The final stage of the insulation of the bathhouse building is the thermal insulation of the external load-bearing walls and decoration with a lining or block house, plaster, cladding panels, facing bricks, cladding stones, etc. They not only perform the function of a respectable finish, but also increase the thermal insulation parameters in turn.

Properly made thermal insulation of the bathhouse will provide comfortable conditions for hygienic procedures, will reduce the costs necessary to form the required temperature and humidity conditions. Insulation will protect building materials and heating equipment from premature wear. The key to successful work and long service life of the thermal insulation system will be the competent selection of heaters.