Foundation insulation

The foundation, as well as the walls, floor and roof of the house, is subject to freezing, because the concrete from which it is erected, very easily conducts cold. According to the good old tradition, many homeowners prefer to insulate the foundation with polystyrene, but this option is acceptable only if there is no threat of flooding the base of the house or the owner of the cottage is limited in finances, because polystyrene can perhaps be considered the most affordable heat-insulating material. Among the huge variety of synthetic materials for thermal insulation, insulation from extruded polystyrene foam, which has no analogues anywhere in the world, is still considered the best. Despite the higher price (when compared with conventional polystyrene foam), insulation with extruded polystyrene foam is more practical and reliable..

Content

- Foundation insulation – to be or not to be?

- Thermal insulation of the foundation with polystyrene foam

- Foundation insulation with polyurethane foam

- The method of warming the foundation with foam

Foundation insulation – to be or not to be?

Very often in the spring, many owners of country houses find cracks on the foundation that appear as a result of skewed structures or deformation caused by heaving of the soil. Of course, it is possible to eliminate these defects, but the cost of such work is quite high. The reason for the distortion of the structures and deformations of the foundation is actually simple. As a result of winter cold weather, soil saturated with moisture undergoes frost frost.

Water, freezing, increases in volume and leads to bloating under the foundation of the building, and this, in turn, leads to the fact that concrete slabs begin to be pushed out of the soil. As a result of such changes, cracks and distortions appear. In addition to heaving, spring snowmelt can also lead to deformation of the foundation. During this process, the soil becomes softer and more plastic, which causes subsidence of the foundation.

Part of these troubles can be avoided if you lay the foundation on a sand cushion about 10 cm thick and use non-porous soil for backfilling, for example, all the same sand. The cost of such work is relatively low, but, as already noted above, these measures will only partially solve the problem. And in order to completely eliminate the possibility of cracks and deformations of the foundation, care must be taken to insulate the foundation with any heat-insulating material, in particular polystyrene foam or polystyrene.

Thermal insulation of the foundation with polystyrene foam

The very works of thermal insulation of the foundation are very simple and even the most remote person from construction will be able to cope with them..

So, around the perimeter of the house remove a layer of soil about 0.5 meters thick and about 1.5 meters wide. Sand of 20 centimeters is poured into the resulting trench and carefully stamped with feet or improvised means. After that, plates of expanded polystyrene are laid on the sand cushion in the entire width of the trench. For reliability, they are glued using bitumen mastic, petroleum bitumen or other adhesives.

The joints between the sheets must be filled with mounting foam or cold bituminous mastic, so that in case of penetration of moisture to the foundation, it does not get inside. When all the work on laying the thermal insulation is finished, you can fill the polystyrene plates with sand. The sand layer should be at least 30 cm. The price of the issue is relatively low, because you can dig a trench yourself, and the insulating materials themselves are not so much.

Expanded polystyrene is a lightweight effective material for warming the foundation

Expanded polystyrene plate, reducing the weight of the supporting structure

Important: the heat loss in the corner zones is much higher, so the polystyrene foam layer in the corners of the house should be 1.5 times larger than along flat surfaces.

Insulation of the foundation with polystyrene foam around the perimeter of the building not only prevents freezing of the soil and prevents the occurrence of deformations and cracks in the base of the house, but also contributes to the thermal insulation of the basement, if any.

This technology of insulation can also be used for thermal insulation of basements, because if you have a desire to convert a cold basement, for example, into a warm gym, it is not necessary to remove the entire soil layer adjacent to the foundation and paste it with insulation to the full height, it will only be enough to do polystyrene insulation as described above.

Foundation insulation with polyurethane foam

Polyurethane foam is a modern heat-insulating material that is ideal for warming foundations, basements and ground floors. It has a number of advantages:

- strong and safe;

- has a low coefficient of thermal conductivity;

- possesses excellent waterproofing characteristics;

- environmentally friendly;

- durable

- not combustible;

- when spraying does not leave cracks and joints;

- quickly applied to walls and foundations;

- does not require any special mounts.

The technology of spraying polyurethane foam completely eliminates the possibility of marriage during installation and allows you to achieve a perfectly smooth coating without gaps. joints and irregularities. When spraying polyurethane foam, the foam as it grows together with the surface of the foundation, filling with itself all the voids.

Thus, a strong, solid, sealed plate is formed, and due to the absence of an air gap, a closed cellular structure of the foam and its low permeability, the possibility of condensation inside the insulation is reduced to zero.

Polyurethane foam spraying technology eliminates cracks and untreated areas

A monolithic layer of insulation coating – a guarantee of reliable protection

Of course, the insulation of the foundation with polyurethane foam is one of the most effective methods of thermal insulation, but at a cost it exceeds both polystyrene foam and polystyrene.

The method of warming the foundation with foam

Polyfoam is the cheapest heat insulating material. It has a porous structure, low coefficient of thermal conductivity and vapor permeability, as well as low density. You need to use polystyrene only if your house is standing on a hill and the threat of flooding the foundation does not threaten you.

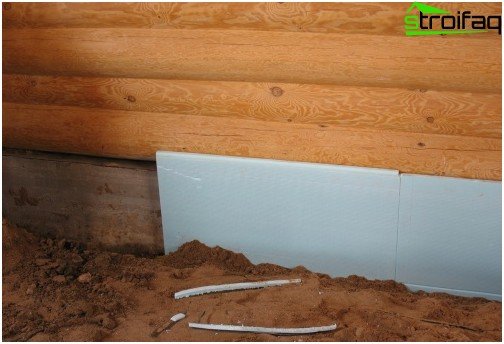

As in the case of polystyrene foam, the base insulation should be started with polystyrene foam from trenches that need to be dug around the entire perimeter of the building to a depth of about 50-60 cm. After this, the polystyrene sheets are glued with bitumen mastic for waterproofing, and then dusted with sand.

Foam base insulation – an easy operational method that does not require professional skills

Polyfoam can insulate not only the foundation, but also the basement, floors and walls of the house.

Important: you need to install any insulation 6-7 days after the end of the waterproofing of the foundation. If thermal insulation is started earlier than this, solvents contained in the waterproofing composition may damage the structure of the expanded polystyrene or foam.

Thermal insulation of the foundation is an important step on the path to your own coziness and comfort, therefore you should not neglect it, but you need to take this process with all responsibility.