How to lay a slab foundation with your own hands

To date, the slab foundation can rightly be called the most common basis for buildings. This is easily explained. Thanks to the robust one-piece construction, performed under the entire area of the structure, he is not afraid of soil movement, because the stove moves with the house. That is why the second name of such a base is monolithic floating foundation.

Content

- Monolithic foundation slab casting background

- Schematic arrangement of the slab foundation

- Advantages of the slab foundation over other types

- How to make a slab foundation with your own hands

Monolithic foundation slab casting background

The base of slabs is the best way out of the difficult situation of erecting structures on problem soils, for example, heaving or subsidence rocks. The construction of the tile foundation is shown with the predominance of moist soil on the site with elevated levels of groundwater standing. The slab foundation is considered ideal for creating waterproof protection for basements and basements.

A slab foundation is needed:

- with soils with low bearing capacity (quicksand, water-saturated sands, bulk soils) and a large load on the base of the house;

- if desired, reduce the possibility of uneven soil compression and sedimentation of the structure;

- if there is pressure groundwater at the construction site.

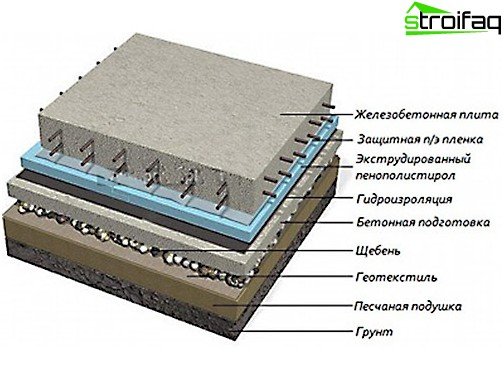

Schematic arrangement of the slab foundation

Visually, the foundation of the slabs is a solid or lattice reinforced concrete slab penetrated by reinforcement. The thickness may vary, depending on the calculation..

The slab foundation consists of the following components:

- drainage pillows;

- waterproofing. It is recommended to arrange not only on the final screed, but also on top of the drainage pillow;

- insulation;

- reinforcing mesh;

- concrete. The minimum value is brand M15 and frost resistance F 75.

Slab foundation: device, arrangement of structural components

The listed components may vary depending on the soil and type of climate. For example, if the climate is close to average, then the insulation can be used only on the side parts of the base.

If construction takes place on loose soils, it is necessary to increase the reliability of the foundation, supplementing it with reinforcing ribs.

Reinforcement base made of grills for pouring slab foundation

For light installations, such as a garage, you can use the economical option – to build a base of grilles with cells 1.5 x 1.5 m.

You need to know!

The thickness of the foundation depends on the weight of the building. For reference: the thickness of the basis of a small house usually does not exceed 25-50 cm.

Advantages of the slab foundation over other types

1. Low cost and ease of manufacture and installation.

2. Good bearing capacity due to the large area of contact with the ground.

3. The general, not subject to local deformation, platform guarantees the integrity of the walls of the house. In the cold period, the structure does not form bends and dips, because it rises and falls evenly. This valuable property is explained by the fact that the foundation is a rigid platform on which walls and columns are located..

4. The ability to use the slabs as a “draft” of the basement floor. In this situation, you can not use additional devices for the ceiling on the basement, which saves a lot of money.

5. The ability to build foundation slabs in complex soils, bypassing earthmoving. This will reduce the costly and time-consuming work in conditions of a high level of groundwater, frozen soil, etc..

How to make a slab foundation with your own hands

Before proceeding with the manufacture of the foundation for the house, you need to calculate the slab foundation. It is at this stage that many developers who want to complete the entire amount of work on their own make irreparable errors.

It is important!

If you do not have a building education, it is unlikely that it will be possible to calculate correctly. many factors need to be taken into account: possible rolls, deformations, shrinkages, load distribution on the entire surface of the plate, etc. Therefore, it is better to contact design specialists who will do everything quickly and efficiently.

The process of pouring concrete over an installed reinforcement cage

The slab foundation: step-by-step manufacturing technology

1. Marking of the construction site and removal of soil.

2. The installation of flooring made of geotextiles in order to create barriers that prevent the passage of sand into clay.

3. The formation of a sand cushion, which consists in filling the site with a mixture of crushed stone and sand, tamping by hand or using a vibrating plate. Sand should be compacted in layers of 10 cm.

4. Laying communications.

5. Production of concrete preparation – screed cast from cement (M-100). Screed thickness – 10 cm. Waterproofing materials are laid on the concrete slab obtained, their joints are soldered with a propane torch or blowtorch. The size of the waterproofing should be larger than the size of the future foundation, which will make it easy to wrap the edges of the flooring up.

6. Thermal insulation made of extruded polystyrene foam is laid on top of the waterproofing layer. The stage is not mandatory, but, in the future, providing a warm floor of the basement, will save on heating the home.

7. On the resulting “sandwich” is mounted fittings. The frame consists of two grids (rods 12-16 mm) with a cell size of 20×20-30-30 cm. The first grid is mounted in the lower part of the foundation (at a distance of no more than 5 cm from polystyrene foam), the second in the upper (below the upper plane of the foundation on 5 cm).

8. A carefully fixed formwork is laid around the perimeter of the slab. Concrete is poured with ramming it manually or with the help of deep vibrators. The surface of concrete is smoothed and smoothed.

9. The concrete slab is covered with a film and settles for 4 weeks. In the first week you should moisten the foundation every day with water.

10. After concrete is fixed, the lateral waterproofing margin is folded up and soldered to the ends of the foundation.

The slab foundation should now dry

Once the solid foundation is ready, you can proceed to further work on building the house of your dreams – cozy, beautiful and reliable. Remember, the correct organization of the process of erecting the foundation of a building is a sure guarantee of stability even on the most “moody” soil.