The fastest way to build the foundation of a building is a foundation of blocks. This method, although it has some disadvantages, is still much more profitable in terms of saving time than, for example, the construction of a monolithic foundation. Of course, any builder will say that working with a solid, even surface is much more convenient, but in order for concrete to reach the desired condition, you will have to wait almost a month, which is neither profitable to the builders or the customer. But the block foundation makes life much easier and makes it easy to fit into the already tight deadlines of our short spring or autumn.

Content

- The first stage is the selection of concrete products

- Classification of concrete blocks

The first stage is the selection of concrete products

Before proceeding with the construction of the foundation, you need to choose high-quality concrete blocks, because the strength of the entire building structure will depend on this.

- The very first (and most important) selection criterion is the boundary load, which will be on the foundation of the future structure. This indicator for each product, subject to the technological process at the plant, has its own numbers.

- We pay attention to the indicator of frost resistance of the blocks. The higher it is, the more severe the conditions your foundation will be able to withstand..

- Look at the presence of granite crushed stone in concrete, which increases the resistance of the house base to acid soil.

- Decide on the size of the blocks. So, for the construction of small objects (cottage, garage, bathhouse), lightweight concrete blocks are used, and for larger buildings it is better to use large products, which will work much faster.

Classification of concrete blocks

If you wondered how to make a foundation of blocks, then you should know that these same blocks are of two types: pillow and wall.

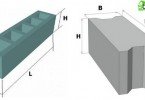

The first in the section form a trapezoid, which helps to decently increase their supporting area. Such blocks are most often used for laying the bottom row of the foundation, which will provide strength and maximum stability of the entire structure. And the latter are in the shape of a quadrangle and can have side cutouts for a more tight fit with each other. Their purpose is the formation of the underground and ground parts of the foundation of the future building.

Thus, the construction of a foundation from blocks implies the use of both wall and pillow concrete blocks. But there is one nuance that should be taken into account in order to facilitate further work – it is desirable that the blocks have technological holes and slots for laying communications, otherwise you will have to hammer them yourself in concrete, and this is very problematic.

There are three types of blocks:

- FBP – U-shaped concrete blocks

- FBV – blocks with cutouts for utilities

- FBS – solid blocks without holes.

All of them have a sufficiently large weight, therefore, for their transportation and installation, the use of lifting equipment will be required, which can cause serious costs. But there is still a way out – you can build a foundation of blocks measuring 20 * 20 * 40 cm, which are designed specifically for the construction of small buildings. Such products are made from concrete, and from lightweight materials, for example, expanded clay concrete. Such a “light” base can withstand the weight of a bathhouse or a single garage without problems, as well as ensure the strength of the structure and its simultaneous insulation. In addition, claydite concrete blocks are much cheaper than other analogues, but there is one point that must be taken into account when purchasing products – their density, which should have a coefficient of at least 1500 – 1800 kg / cubic meter. Unfortunately, it is impossible to verify this indicator “by eye”, therefore the only advice that can be given in this case is to buy blocks only in a trusted place and from a reliable manufacturer.

The second stage – marking the soil

At this stage of construction, it is necessary to mark the soil: to outline the boundaries of the future construction and foundation. This is best done with metal pegs, a rope and a building meter.

Important: when marking, it is worth considering that the width of the foundation should be greater than the width of the wall.

After the marking work is completed, you can begin to prepare the soil for the construction of the foundation, and for various types of foundations of the future house or other structure, various earthworks are carried out. So, for a columnar foundation, it is necessary to dig holes around the perimeter of the marking and inside it a depth of about one and a half to two meters, and for the strip type the top layer of soil is removed and a trench is excavated, which should be several centimeters wider than the blocks.

The marking is carried out taking into account the width of the foundation exceeding the width of the wall

Important: the depth of the trench depends on the type of soil: for sandstones with an aquifer depth of more than 2 meters, it will be enough to dig a trench 30-40 centimeters deep, and in other cases you will have to go deeper into a more decent distance.

Third stage – construction

If the first two stages are preparatory, then the third stage is the main stage of construction, which must be taken with all responsibility.

The technology of erecting a foundation construction of blocks

The technique of building any type of foundation from blocks is about the same.

- All elements of the foundation are fastened together by ordinary cement mortar, which is prepared immediately before masonry. During construction of the foundation, water or cement should not be added to the solution, since excesses of one or the other can weaken the contact.

- Blocks are stacked on top of each other like brickwork. Minimum deviations of the block rows from the horizontal are allowed no more than 15 mm per 10 meters of masonry.

- All joints and seams should be filled with the solution to the maximum so that there are no gaps or gaps..

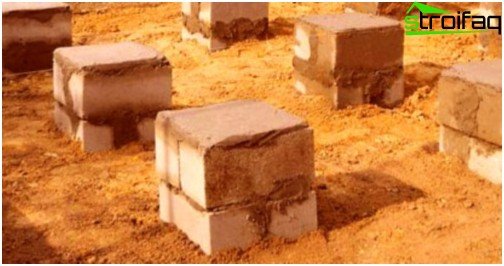

Column type base for home

This type of foundation can be attributed to the cheapest options for erecting the foundation of the future building. It represents a certain number of supporting tables, dug deep into the ground. These cabinets are located around the perimeter of the marking and inside it. They use a columnar foundation for light buildings, such as wooden baths, garages or country houses. By the way, it is built quite quickly and simply (in one day you can manage to finish all the work related to the foundation).

Along the perimeter of the future structure, pedestals are installed in prepared pits with a height of at least 40 centimeters. The number of pedestals depends on the size and weight of the building. But, before you start installing concrete poles, you need to pre-prepare the pits. To do this, we ram the bottom with a suitable tool for this (you can even take an ordinary long stick), then we fill in gravel (about 10-12 cm) and sand (5-7 centimeters). We level the surface of the sand and install the first row of blocks, fixing them with cement mortar.

Build such do it yourself foundation of the blocks is quite simple, but there is one nuance that must be taken into account. The fact is that the slightest inaccuracy or error can cause distortions, which will then be problematic to correct (the cement has already hardened), therefore, when erecting a columnar foundation, you need to carefully monitor the level of the pedestals using a rope stretched between the supports.

Column foundation – an economical solution, the efficiency of construction

Round concrete pedestals are installed around the perimeter of the building.

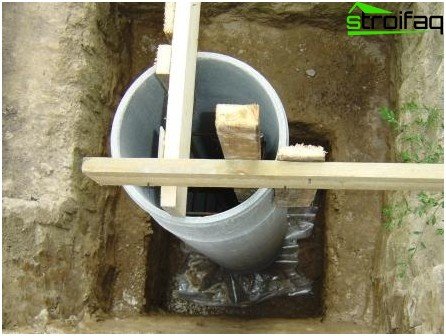

Block footing

The strip foundation for a house of blocks is ideal for the construction of buildings of brick or cinder blocks. It is a concrete strip located under all supporting structural elements..

In both the first and second cases, it is best to use expanded clay concrete blocks to build the foundation, since they are much lighter (about 30 kg) than ordinary concrete, and their size allows you to work without much stress and difficulty.

The strip foundation from the foundation blocks is erected according to a scheme similar to the column foundation construction scheme, only the filtering “pillow” of crushed stone and sand is placed in trenches. For the bottom row, pillow blocks are used, and they need to start laying from the corners and places of intersection of future walls. Having installed the corner elements, you need to check the correctness of the installation with the help of the level and only after that you can proceed to further laying, focusing on the rope that is pulled between the first blocks. After finishing the installation of the bottom row, it is necessary to lay a waterproofing layer, which will prevent the penetration of moisture to the foundation.

Next, using metal pins, mark the places for the lighthouse wall elements of the second row, cover the bottom row with cement mortar and install the next row of blocks.

The installation of concrete blocks is carried out similar to brickwork

The construction of the strip foundation of concrete blocks

Disadvantages of foundations of foam concrete elements

Of course, the construction of a foundation of blocks has a lot of advantages, among which, in the first place, of course, the installation speed. But this advantage is also a disadvantage, because the cost of a prefabricated foundation is almost 30% higher than monolithic. In addition, the issue price may increase by another 20-25% if you choose large blocks for construction, transportation and installation of which requires additional costs.

Another fat minus is the intermediate seams through which moisture or rot can penetrate. A sad outcome can only be prevented by careful waterproofing..

Now you know how to build a foundation from blocks, you know the nuances of this process and its shortcomings, it remains only to begin. Good luck!