How to make a foundation for a garage with your own hands

Even a person who does not understand the construction business understands that any building must have a solid foundation. At the same time, it does not matter at all whether you are building a two-story spacious house or a garage for a car, the foundation must be reliable and durable. Let’s look at how to make a foundation for a garage so that during construction and operation there are no problems. To independently carry out this process, you need to know all the important steps.

Content

- Geological survey – an important preliminary stage

- Garage foundation tools

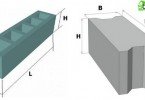

- 1. Reinforced concrete blocks

- 2. Fixed formwork for pouring a monolithic base

- 3. Removable formwork – the most common way

Geological survey – an important preliminary stage

Soil sampling from wells

Before building a foundation under do-it-yourself garage it is necessary to conduct geological research. They will give an idea of the depth of groundwater and the composition of the underlying strata. This process consists of sampling from small wells at the site of future construction. The following is an analysis of the samples taken..

On soils that are oversaturated with water or poorly absorb moisture, a drainage system is mandatory.

Inexperienced owners, making the foundation under the garage with their own hands, skip this stage of preparation. But in vain. Such irresponsibility leads to undesirable consequences. In winter, the water in the ground freezes and expands, and thaws in spring. This leads to deformation of the foundation, and maybe the garage itself.

Based on the results of soil research, choose the type of foundation and the depth of laying

Therefore, in no case do not neglect this stage of construction. Well, here is the composition of the soil determined. The next stage, the calculation of the foundation for the garage, it is advisable to entrust the specialists.

But if you decide to do everything yourself, know that the depth of the foundation for the garage depends on the type of soil. Approximately it looks like this:

- Rocky. Very dense, requiring great effort during processing. But on the other hand, a garage can be built immediately on a level site without digging a trench.

- Gravel. The depth of the foundation should not be lower than the freezing depth.

- Clayey. Depth of foundation is below freezing depth.

- Sandy. Foundation Depth: 40-70 cm.

- Sandy loam. Depth of foundation not less than 2 m.

- Peat bogs. It is impossible to build on such soils, you need to make a peat to the mineral base (completely remove the peat layer and replace it with gravel and sand).

Garage foundation tools

Reinforced concrete blocks

For this method, in addition to the blocks themselves, lifting equipment and a hired team of builders will be needed. Without this, you will not be able to independently install heavy reinforced concrete structures in the trench. This method is the most expensive..

Fixed formwork for casting a monolithic base

The main preparatory element in this case is the construction box. After completion of work, it is one of the components of the construction of the foundation. This element can be made of concrete or expanded polystyrene. In the first version, reinforcement is laid between two concrete slabs and poured with concrete.

In the second, polystyrene sheets are used instead of reinforced concrete slabs. This method provides additional insulation of the foundation and is very easy to perform. Even the person who is not knowledgeable in construction will be able to put together and fasten the necessary elements. Homemade fixed formwork is difficult to manufacture and not everyone can do it right. Therefore, rarely does anyone resort to this method.

Removable formwork – the most common way

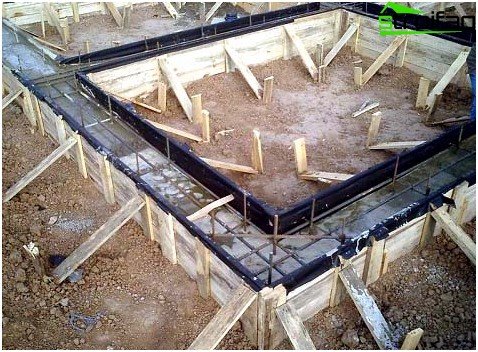

Trench for the installation of a monolithic strip foundation (or pile with a buried grillage)

Garage foundation steps

Let’s take a closer look at how to make a foundation for a garage using removable formwork. First, a plan for future construction is outlined in the selected area. Necessary tools: wooden stakes, tape measure, rope. Stakes are driven into the corners of the proposed structure, between which a rope is stretched.

Moreover, the width of the foundation is greater than the width of the wall by twenty centimeters. But the depth of the foundation for the garage depends on the composition of the soil. The bottom of the dug trench is covered with sand (5 cm) and crushed stone (10 cm). This process is done in several stages, after each layer is carefully pressed.

Installation of formwork for pouring the foundation

Garage foundation formwork

Some believe that building a foundation for a garage is a difficult task because of the installation of formwork. But they are wrong. This process is laborious, but doable. Formwork is a box, the basis for pouring concrete, which is removed after the mortar hardens. It consists of wooden panels tightly fitted to each other so that there are no gaps through which the solution can flow. All boards must be installed evenly (use a level for this) and firmly. To do this, install supports on the outside..

Reinforcement gasket

An iron net is made of iron rods 10-12 mm thick. To do this, 2 rods are placed 5 cm above the bottom of the pit at a distance of 5 cm from the formwork, short rods are laid across which. The distance between the short rods is 40-50 cm. The “mesh” is fastened at the intersections by a special wire or by welding. Vertical bars are also attached here. After 20-30 cm, the following short rods are welded to them. The result should be a lattice.

Pouring concrete formwork

Leveling and tamping of cement is carried out after pouring until the mortar has hardened.

After the preparatory work, one question remains: how to fill the foundation under the garage? This step should be performed at a time. Otherwise, joint seams may form. One person will not be able to perform this operation correctly and quickly, so it is advisable to have assistants. During concrete pouring, waterproofing is done at the level of the “base” of the foundation. For this purpose, roofing material is used..

After pouring the foundation, it must be maintained in compliance with the temperature and humidity conditions and protected from direct sunlight and wind. Therefore, in the summer, the structure is covered with moisture-intensive materials (dense fabric, burlap, matting) and periodically irrigated with water. On rainy days, the surface is covered with waterproofing material, protecting it from excessive moisture. The top of the foundation is leveled until the concrete has frozen. Formwork is removed only after the mortar is completely solidified.

Do not remove the formwork panels until the mortar completely hardens.

Since concrete hardens for quite a long time, it is advisable to produce the foundation for a garage a couple of months before the construction of the walls. The foundation is an underground structure that must withstand the load from the structure. The main requirements put forward for these structures – resistance to external influences, stability and durability, subject to technological rules, will be “on top”.