Do it yourself garage frame

For many, a car is much more than just a means of transportation. This is a reliable assistant and a faithful life companion who needs care and care. The problem of proper storage deserves special attention, because the “caravan” must meet a number of requirements. Previously, its construction could hardly be called a simple task, but modern construction technologies made it possible to build a frame garage with your own hands in the shortest possible time, while spending a minimum of money.

Content

- Garage Construction Requirements.

- What is a frame garage?

- How to build with your own hands?

- Preparatory work.

- Foundation laying is an important stage.

- Assembling the frame for the garage.

- Making the roof by the rules.

- Go to the wall cladding.

- Installation of garage doors.

- Internal rational arrangement.

Garage Construction Requirements

In order for the garage to be durable and to cope with the duties assigned to it to store your car flawlessly, you need to know what qualities it should have:

- the strength of the structure for effective protection against external influences;

- low thermal conductivity, which is necessary to ensure optimal temperature conditions and reduce the cost of heating the room;

- simplicity of design, allowing to carry out the whole range of work independently;

- low cost;

- minimum deadlines.

What is a frame garage?

Frame construction has recently become extremely popular. Lightweight construction (LMK), made most often of wood, is placed on a light base. But this does not mean that the construction will be fragile: in terms of durability, the frame garage can successfully compete with analogues from foam blocks and metal.

Frame garage has many advantages

Wonderful technology was donated by the Swedes, so such facilities are also called Swedish. The invention was immediately appreciated, as he has a lot of advantages.

Simplicity and maximum speed are the main advantages. Due to the fact that the components are connected by bolts and screws, installation work can be carried out at any time of the year. The forces of 2 installers are more than enough to build a frame garage in a few days.

It is also important that the need for rental of specialized construction equipment disappears as unnecessary. To worry about the clutter of construction waste with the site is also unnecessary – it simply will not be.

How to build with your own hands?

Before proceeding with the construction, it is necessary to develop a project of a frame garage that reflects the sequence of stages and calculation of the required materials. Next, you need to think about the location. If you have a 10×10 meter platform at your disposal, consider the first step.

It is important! The project plan can be ordered from professional designers or downloaded on one of the many online sites.

Preparatory work

To start the frame construction of the garage you need with the preparation of the territory. The site is cleared of vegetation, leveled and rammed. For the future foundation, a gravel-sand cushion is created, which is leveled with a vibrating plate to obtain a smooth surface.

Sand and gravel preparation

Foundation laying is an important stage

As you know, the foundation is the foundation of any structure, providing strength. The choice of the type of foundation depends on various factors: the design of the garage, soil features, economic feasibility. Most often, this role is played by a monolithic concrete slab, serving at the same time as a floor, which can be faced with any materials. Concrete slab – a kind of “floating” base, perceiving loads evenly, which helps to avoid deformation of the structure.

A shallow trench is dug around the perimeter of the surface, after which the formwork is installed.

It is important! Please note that the formwork is installed on three sides of the future garage.

Of great importance is the quality of concrete poured into the formwork; products without a certificate should not be purchased. To give the plate strength, it is provided for the installation of monolithic stiffeners and reinforcement with two reinforcement meshes.

Foundation garage frame

We leave the resulting foundation for 3 weeks.

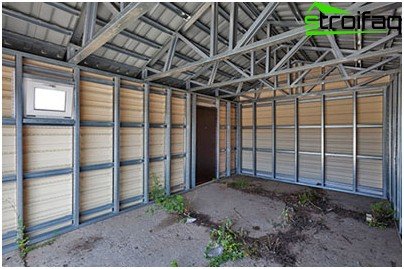

Assembling the frame for the garage

After the foundation has completely frozen, the construction of a frame garage with your own hands involves the construction of a “skeleton”. The lower harness is made of 100×50 boards pre-treated with an antiseptic.

For corner posts and gates, bars of 100×100 size are used, for the remaining parts – floor beams and rafters – 100×50. Between the racks of the lower harness they withstand a step of 120 cm. In the lower harness, the grooves for the racks can be omitted, then the fastening will be carried out using self-tapping screws and nails. By the way, this method is much simpler..

To give the frame strength, braces should be installed in the corners. Do not forget to provide space for windows and gates..

Garage wooden frame

If a building with a width of more than 4 meters is planned, it is better to make ceiling beams from 50×100 boards, which are much stronger. Longitudinal elements are made of bars of at least 50×50. This stage in time will take several days.

Making the roof by the rules

Further, the construction of a garage using frame technology goes into the next important stage – the arrangement of the roof. To do this, you need 100×25 boards, which will be sheathed with corrugated roofing material. Bitumen sheets laid directly on the crate will do a wonderful job with this role. It’s not necessary to insulate the attic of the garage, they will be quite enough.

Many prefer corrugated or metal tiles for roofing – you do not need to adjust the sheets, and large dimensions significantly accelerate the progress of work. Fasten materials with simple electric tools.

Spillway – an important detail of the roof

A mandatory component of the roof is a spillway, which can be made from a halved plastic sewer pipe. In any case, polymer protection is required to prevent rust..

Go to the wall cladding

For external cladding, the lining of the “C” class is best suited, on which a windproof layer consisting of vertical beams 25×30 and a dense glassine is fixed.

It is important! The recommended step when installing vertical bars is 30 cm. Do not forget about the processing of wooden parts with an antiseptic.

Inside the garage is insulated with mineral wool and cheaper lining. The outer cladding is made of siding. Double-glazed windows are inserted into pre-arranged openings.

Installation of garage doors

Garage door can be any: sectional, sliding, sliding, but most often, especially when building on their own, swing gates are found. They are easy to manufacture, reliable and light..

Dimensions will depend on the dimensions of the car, the standard version is 2.5 meters. From the metal corner (65 mm), the inner and outer gate frames are made, which are fastened together by metal strips. If you want to use the top of the frame as a jumper, then you need to completely sew it up with metal.

The sash frame is made of a metal profile (40×25); after assembly, the frame is sheathed with 2 mm thick sheet steel. The metal pins inserted into the tubes will serve as a deadbolt, you can use the deadbolt, closing on the principle of a milk can.

Gates should open easily

In the manufacture of gates, it is important to provide corrosion protection. The metal is processed with sandpaper and a file, covered first with linseed oil, and then with paint.

Internal rational arrangement

That’s all. The task, called how to build a frame garage, is almost solved, it remains only to think about the internal arrangement. The ceiling is lined with lining, a layer of paper and insulation is laid on top of it. A 25 mm thick board is laid on the attic floor, a ladder is installed.

You should also consider heating. Widely used spiral electric heaters are not allowed. Portable industrial heating systems are also far from the best option, since their heat transfer is low. The most effective means is water heating with an individual heat source. The principle of operation is based on the difference in the weight of hot and cold water, due to which a unidirectional channel of hot liquid appears. Water heated in the boiler rises to the upper part, enters the convector, where it gives off heat, is cooled and, descending, enters the boiler again.

As an alternative to this type of heating, you can use a 2 kW fan heater or a 500 W floodlight.

So the garage looks inside

It is important! The temperature in the garage should be at +16 degrees, this is enough for body work.

So the construction of a frame garage made of wood has ended, and now you are a happy owner of a reliable house for your car, which will protect it in any weather and provide comfortable conditions for repairs when such a need arises. Well, if you have not decided on the appearance of the future garage, the presented photo selection will help you with this.

Do-it-yourself frame garage: photos

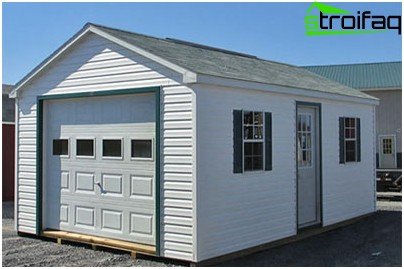

Design Option No. 1

Design option number 2

Design Option No. 3

Design option number 4

Design option number 5