Metal garage

I don’t want to throw a brand new car at night in the open air, since there is a great threat of theft, and the atmospheric effect is bad for the condition of the body. It is good if it is possible to rent a parking space or a garage in a covered parking lot. But ideally, it is better to build a metal garage with your own hands near your house.

Content

- What attracts a metal garage

- Choosing a place for a garage

- Material for construction

- The project is the basis of construction

- Local breakdown

- Do-it-yourself garage in stages

- Foundation and floor

- Assembling a metal garage

- Installation of garage doors

- How and what to insulate?

What attracts a metal garage

Garages are stone, wooden, block or metal. It is undesirable to erect wooden structures due to fire hazard, wooden structures will be folded for a long time, but without the skills and abilities in the construction business it is better not to undertake such an undertaking. But how to make a metal garage with your own hands, every car owner is able to understand. In addition, repairing metal garages is not that difficult.

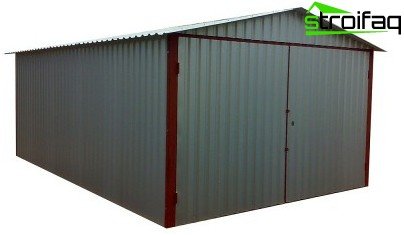

A metal garage is an economical solution to the construction problem, which does not require a powerful foundation and significant costs

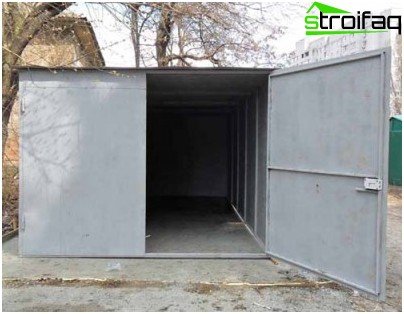

Prefabricated metal garages have their advantages, which include: high fire resistance, the relative cheapness of the material, protection from vandals. A metal garage is not considered a capital building, and therefore no documentation is required for its construction.

A metal garage for a car can be built quickly enough. In this case, it will not be necessary to fill the solid foundation and masonry of the brick walls of the garage – you just need to assemble the tiled floor together, build the simplest supporting base and garage frame from metal. The metal garage is collapsible, although it is simple in design and construction, but some details still need to be done in stages.

Such garages are welded and frame. The first buildings are durable and more stable, but the second buildings are faster and easier to build, they can be disassembled and transported to a new place if necessary. The choice of variety depends on how long, for what and where it is planned to build a garage.

Choosing a place for a garage

The crucial stage of construction is the choice of a place for the construction of a garage. The building should be located at some distance from the house and at the same time not adjacent to the windows. Do not build a garage in lowlands, flooded by melt and rainwater.

Entrance to the garage should be free and convenient, the building itself should not block the windows of residential buildings

Access to the garage should be convenient. The area of construction depends on the brand of the car, the most common are sizes 3.6 by 7 meters. When planning dimensions, it is recommended to consider not only the dimensions of the car, but also a place for spare tires, tools, a pump and other accessories.

Material for construction

To build a metal garage with your own hands, you will need such materials: metal sheets, insulation, profiles, load-bearing elements – round or profile pipes, fasteners, lining, ingredients for concrete.

Metal sheets are preferably galvanized, protected from rust. The best material for a metal garage is professional flooring. It is reliable and durable, but has one drawback – the relative high cost. Primed sheet is much cheaper, but it is unstable to temperature extremes and precipitation, and therefore will not last long.

The project is the basis of construction

The construction begins with a metal garage project. It does not have to be a roll of drawings, but the structure must be drawn and described on paper. At the design stage, it is worth identifying the tasks that the metal garage will solve: will the garage serve solely as a parking place for the car, or is it supposed to carry out repair work, is it necessary manhole.

The project of a metal garage should take into account the dimensions of the car with a view to the prospects of acquiring a larger car

It is also necessary to determine the size of the garage, based on the characteristics and area of the site on which it is planned to place the building, as well as on the tasks that the owner expects to solve from him. For parking a car, a garage measuring 3 by 5.5 meters will be enough, of course, if the car is not a “hammer”. Of course, the size of the building should be increased if some equipment is located in it..

Local breakdown

At this stage, the drawing of the metal garage should be transferred to the real area. To do this, you need a dozen pegs that have a length of 40 centimeters. You can take pieces of reinforcement, the diameter of which reaches 10 – 12 millimeters, a small sledgehammer or heavy hammer, tape measure – at least 5 meters in length, and also a nylon cord – 30 – 40 meters.

A monolithic foundation is poured if it is not intended to construct a viewing hole and a cellar

For reference to the terrain of the garage, you must at least know the point at which one corner will be located. And, of course, the placement of the garage in space relative to this point. The garage can be attached to the existing line of garages. Other accommodation options are possible – the garage can be erected standing separately.

Do-it-yourself garage in stages

Fundamentally, the construction technology of this building is not much different from the construction standards of any type of structure.

Foundation and floor

Making metal garages is always worth starting with the floor. At the corners of the site, it is customary to dig in the support racks. If you intend to equip a viewing hole, then you need to dig it in advance. The space inside the racks must be filled with concrete. The thickness of the slab-type pillow made of concrete for a metal garage should not be large – approximately 10-15 centimeters above ground level.

The garage is located at a certain elevation so that liquid precipitation and melt water do not get inside the building

It is necessary to make the elevation of the foundation so that water does not fall into the garage. Concreting the floor in a metal garage is much easier than pouring the floor in a stone building. The floor must be absolutely even, without cracks and bulges. Do not forget that in the direction where the gates will be located, it is necessary to make a congress. According to statistics, a minimum of 2 to 3 meters of cubic concrete will be required to fill the floor.

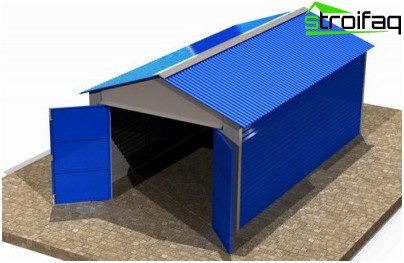

Assembling a metal garage

First you have to make a frame. Vertical racks are interconnected by profile slopes along the bottom, top and center. The frame is best welded, although connections with fasteners are allowed.

Metal garage frame

The ceiling should be given special attention. In a metal garage, the roof should be gable, so you need to build triangular profiles over the frame upper ceiling. After the construction of the frame, the metal garage should be sheathed with metal sheets that can be welded or screwed to the frame with screws. Prefabricated metal garage in the latter case, quickly and easily disassembled.

Installation of garage doors

This stage is the most time-consuming and responsible part of the work, however, you can purchase ready-made gates. The frame is usually made of angle metal, welded to the racks of the garage and sheathed with a sheet. Preferably, the width of the gate should be 2.5 meters or more. Particular care must be taken to locks. It is recommended to embed two – the main lock and the lock that blocks access to the opening for the key of the main lock.

Gates of a metal garage – the simplest type of swing

How and what to insulate?

So, the garage is built! Now it’s worth learning how to insulate a metal garage. Buildings made of metal are able to heat up very quickly in the sun, but then also cool quickly in frost, which is why the problem of insulation is acute. Many motorists with the onset of winter ask this question. Warming is carried out as in a classic garage. Polyfoam, glass wool and other similar heaters will come to the rescue.

Mineral wool is best suited for thermal insulation. Its main advantages are low thermal conductivity and fire resistance. Foam is used as insulation for the sake of cheaper construction, but it is worth remembering that this material is combustible. Although modern brands of foams are characterized by excellent self-extinguishing.

Thermal insulation will allow you to maintain the mode necessary for storing a car

The insulation material is usually covered with a casing. There are several types of cladding. For example, plain steel coated with standard primer. The professional flooring made on a steel basis with a zinc coating acts as a more reliable option during construction. As cladding, PVC, DPS, fiberboard or wood are often used..

Arrangement – create conditions

There are some more details in the construction of a metal garage. This primarily relates to ventilation, which is necessary to prevent accumulation of moisture on the surfaces of the building, as well as to remove fumes and harmful gases. The best option is the supply and exhaust ventilation.

Garage arrangement: with proper organization in the garage you can store a lot of things and they will not interfere with work

If it is planned that the car will warm up in the garage, then it is worth making a hole in the wall, letting the rubber tube through, pull one end out, and secure the other to the muffler of the car. If desired, electricity can be drawn into the garage, shelves and lockers can be placed along the wall. It is better to paint the roof and the outer walls of the garage with light paint, because this way they heat less in the sun.

Many useful ideas on garage arrangement you will find on our website.

Now the installation of the metal garage is finished! The frame structure will reliably protect the “iron horse” from bad weather, extend the useful life of the machine and protect it from theft.